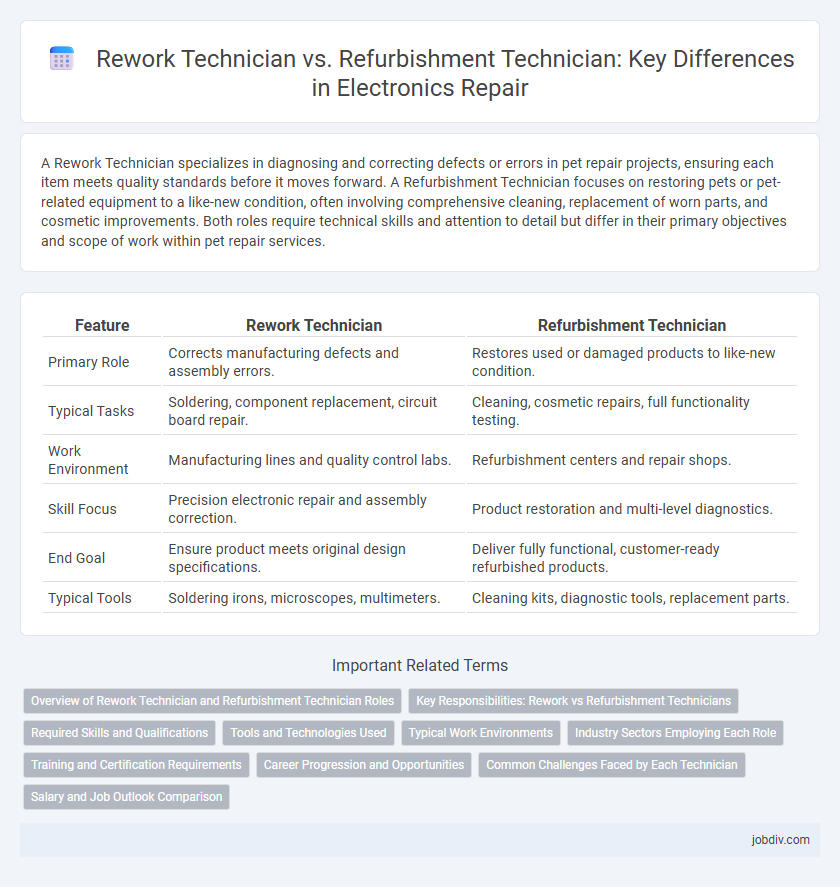

A Rework Technician specializes in diagnosing and correcting defects or errors in pet repair projects, ensuring each item meets quality standards before it moves forward. A Refurbishment Technician focuses on restoring pets or pet-related equipment to a like-new condition, often involving comprehensive cleaning, replacement of worn parts, and cosmetic improvements. Both roles require technical skills and attention to detail but differ in their primary objectives and scope of work within pet repair services.

Table of Comparison

| Feature | Rework Technician | Refurbishment Technician |

|---|---|---|

| Primary Role | Corrects manufacturing defects and assembly errors. | Restores used or damaged products to like-new condition. |

| Typical Tasks | Soldering, component replacement, circuit board repair. | Cleaning, cosmetic repairs, full functionality testing. |

| Work Environment | Manufacturing lines and quality control labs. | Refurbishment centers and repair shops. |

| Skill Focus | Precision electronic repair and assembly correction. | Product restoration and multi-level diagnostics. |

| End Goal | Ensure product meets original design specifications. | Deliver fully functional, customer-ready refurbished products. |

| Typical Tools | Soldering irons, microscopes, multimeters. | Cleaning kits, diagnostic tools, replacement parts. |

Overview of Rework Technician and Refurbishment Technician Roles

Rework Technicians specialize in correcting defects and performing targeted repairs on electronic components and assemblies to restore functionality and ensure compliance with quality standards. Refurbishment Technicians focus on restoring used or returned products to a like-new condition by thoroughly inspecting, cleaning, replacing worn parts, and reassembling equipment for resale or reuse. Both roles require technical expertise but differ in scope, with Rework Technicians addressing specific faults and Refurbishment Technicians managing comprehensive product overhaul processes.

Key Responsibilities: Rework vs Refurbishment Technicians

Rework Technicians specialize in identifying and correcting defects on individual components or assemblies, focusing on precision soldering, component replacement, and circuit board repairs to restore functionality. Refurbishment Technicians handle comprehensive restoration processes, including disassembly, cleaning, testing, and upgrading of entire devices to meet manufacturer specifications and performance standards. Both roles require detailed inspection and quality control, but Rework Technicians primarily address localized issues while Refurbishment Technicians manage complete product revitalization.

Required Skills and Qualifications

Rework Technicians require proficiency in diagnosing and correcting assembly defects, strong soldering skills, and familiarity with printed circuit board (PCB) layouts, often needing certifications like IPC-A-610 or J-STD-001. Refurbishment Technicians must excel in disassembly, cleaning, component testing, and restoring hardware to original specifications, typically demanding knowledge of electronic components and experience with testing equipment such as multimeters and oscilloscopes. Both roles prioritize attention to detail and adherence to quality standards but differ in technical focus and certification requirements.

Tools and Technologies Used

Rework Technicians primarily use precision soldering irons, microscopes, and hot air reflow stations to repair and replace specific components on circuit boards. Refurbishment Technicians rely on advanced cleaning systems, diagnostic software, and automated testing equipment to restore entire devices to functional condition. Both roles require familiarity with ESD-safe tools and surface mount technology (SMT) equipment, but Rework Technicians focus more on micro-level repairs while Refurbishment Technicians handle broader device-level restoration processes.

Typical Work Environments

Rework Technicians typically operate in manufacturing facilities, electronics assembly lines, or quality control labs where precise repairs and adjustments are made to defective products. Refurbishment Technicians usually work in recycling centers, appliance repair shops, or specialized refurbishment plants focused on restoring used or returned items to like-new condition. Both roles require controlled environments with access to diagnostic tools, testing equipment, and repair workstations tailored to specific product categories.

Industry Sectors Employing Each Role

Rework technicians are primarily employed in electronics manufacturing and automotive industries, where they focus on correcting defects and ensuring product quality during production. Refurbishment technicians find roles in consumer electronics, healthcare equipment, and aerospace sectors, specializing in restoring used or returned products to like-new condition. Both roles demand specialized skills but cater to different stages of the product lifecycle in various manufacturing and service industries.

Training and Certification Requirements

Rework Technicians typically require specialized training in soldering techniques, component replacement, and troubleshooting electronic assemblies, often holding IPC-A-610 and J-STD-001 certifications to ensure quality standards in rework processes. Refurbishment Technicians focus on restoring equipment to like-new condition, necessitating comprehensive knowledge in diagnostics, cleaning methods, and functionality testing, with certifications such as Certified Electronics Technician (CET) or relevant OEM training. Both roles demand continuous education to keep pace with evolving technologies and industry standards in repair and refurbishment sectors.

Career Progression and Opportunities

Rework Technicians specializing in detailed component-level repairs often advance to roles in quality control or process engineering, leveraging their precision skills in high-demand manufacturing environments. Refurbishment Technicians, who focus on restoring entire products to like-new condition, frequently progress toward supervisory positions in remanufacturing or product lifecycle management, benefiting from their broad technical and project coordination experience. Career opportunities for both paths expand significantly in industries such as electronics, automotive, and aerospace, where sustainable resource management and cost efficiency drive ongoing demand for skilled technicians.

Common Challenges Faced by Each Technician

Rework Technicians commonly face challenges such as identifying subtle defects in complex electronics and ensuring precise component replacement without damaging adjacent parts. Refurbishment Technicians often struggle with restoring varied used devices to like-new conditions while managing inconsistent wear and unpredictable hardware failures. Both roles require advanced diagnostic skills and meticulous attention to detail to maintain stringent quality standards.

Salary and Job Outlook Comparison

Rework technicians typically earn a salary ranging from $40,000 to $55,000 annually, with job growth projected at 5% over the next decade due to steady demand in manufacturing and electronics industries. Refurbishment technicians often command higher salaries, averaging $50,000 to $65,000 per year, driven by increasing consumer interest in sustainable and cost-effective product alternatives. The job outlook for refurbishment technicians is robust, with a projected growth rate of 7%, reflecting expanding markets in electronics, appliances, and industrial equipment refurbishment.

Rework Technician vs Refurbishment Technician Infographic

jobdiv.com

jobdiv.com