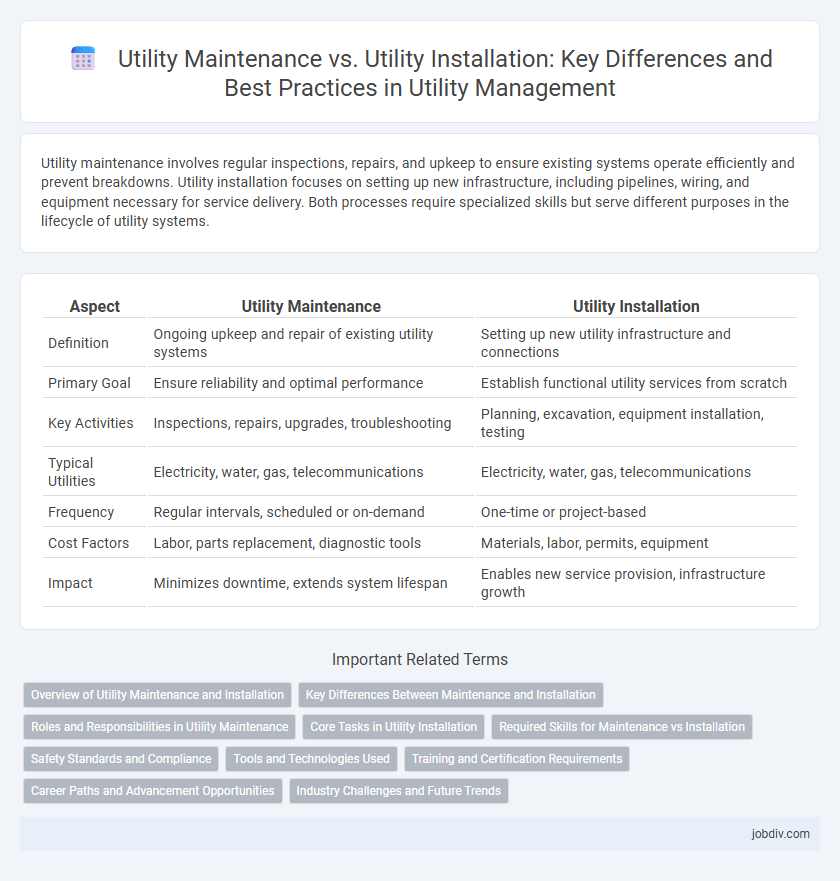

Utility maintenance involves regular inspections, repairs, and upkeep to ensure existing systems operate efficiently and prevent breakdowns. Utility installation focuses on setting up new infrastructure, including pipelines, wiring, and equipment necessary for service delivery. Both processes require specialized skills but serve different purposes in the lifecycle of utility systems.

Table of Comparison

| Aspect | Utility Maintenance | Utility Installation |

|---|---|---|

| Definition | Ongoing upkeep and repair of existing utility systems | Setting up new utility infrastructure and connections |

| Primary Goal | Ensure reliability and optimal performance | Establish functional utility services from scratch |

| Key Activities | Inspections, repairs, upgrades, troubleshooting | Planning, excavation, equipment installation, testing |

| Typical Utilities | Electricity, water, gas, telecommunications | Electricity, water, gas, telecommunications |

| Frequency | Regular intervals, scheduled or on-demand | One-time or project-based |

| Cost Factors | Labor, parts replacement, diagnostic tools | Materials, labor, permits, equipment |

| Impact | Minimizes downtime, extends system lifespan | Enables new service provision, infrastructure growth |

Overview of Utility Maintenance and Installation

Utility maintenance involves the regular inspection, repair, and upkeep of existing utility systems such as water, electricity, gas, and telecommunications to ensure efficient operation and prevent service disruptions. Utility installation encompasses the planning, design, and construction of new utility infrastructure, including laying pipes, cables, and setting up transformers or substations for expanded service coverage. Both processes are critical for the reliable delivery of essential services and require adherence to regulatory standards and safety protocols.

Key Differences Between Maintenance and Installation

Utility maintenance involves routine inspections, repairs, and upkeep of existing systems to ensure optimal performance and prevent breakdowns, whereas utility installation focuses on the initial setup and deployment of new infrastructure such as water lines, electrical grids, or gas pipelines. Maintenance requires continuous monitoring and timely response to wear and faults, while installation emphasizes planning, design, and adherence to regulatory standards during construction. Both processes demand specialized expertise, but maintenance prioritizes longevity and system reliability, contrasting with installation's goal of establishing functional utility networks.

Roles and Responsibilities in Utility Maintenance

Utility maintenance involves routine inspections, repairs, and preventive measures to ensure reliable operation of electrical, water, gas, and communication infrastructure. Maintenance teams are responsible for troubleshooting faults, performing scheduled upgrades, and adhering to safety regulations to minimize service disruptions. Effective utility maintenance demands coordination with field technicians, monitoring systems, and immediate response to emergencies to uphold public safety and utility efficiency.

Core Tasks in Utility Installation

Utility installation centers on core tasks such as trenching, laying pipes or cables, and connecting new systems to existing infrastructure. Precision in mapping and adherence to safety standards are critical during the placement of water, gas, electrical, or telecommunications lines. Proper utility installation ensures infrastructure reliability, reduces future maintenance needs, and supports urban development efficiently.

Required Skills for Maintenance vs Installation

Utility maintenance demands strong diagnostic skills, proficiency in troubleshooting, and knowledge of safety protocols to keep existing systems operational. Utility installation requires expertise in reading blueprints, handling tools for physical setup, and understanding regulatory compliance to ensure proper system deployment. Both roles necessitate technical knowledge, but maintenance prioritizes problem-solving and system longevity, while installation emphasizes precise construction and initial system integrity.

Safety Standards and Compliance

Utility maintenance ensures ongoing adherence to safety standards by regularly inspecting and repairing existing infrastructure to prevent failures and hazards. Utility installation demands rigorous compliance with current safety codes and regulations during the construction phase to guarantee system integrity from the outset. Both processes prioritize regulatory compliance to protect workers, users, and the environment from potential safety risks.

Tools and Technologies Used

Utility maintenance relies heavily on diagnostic tools such as thermal imaging cameras, ultrasonic leak detectors, and smart sensors to monitor system performance and prevent failures. Utility installation involves advanced machinery including trenchers, directional boring drills, and cable pulling equipment to ensure efficient and accurate infrastructure deployment. Both processes increasingly integrate IoT technology and GIS mapping software to enhance precision and real-time data analysis.

Training and Certification Requirements

Utility maintenance demands specialized training in equipment diagnostics, safety protocols, and preventive measures to ensure system reliability and minimize downtime. Utility installation requires certification in construction standards, electrical or pipeline systems, and compliance with regulatory codes to guarantee proper setup and long-term functionality. Both fields prioritize continual education to stay updated with evolving technologies and industry best practices.

Career Paths and Advancement Opportunities

Utility maintenance careers focus on repairing and upgrading existing infrastructure, requiring strong problem-solving skills and technical expertise in diagnostics. Utility installation roles emphasize the construction and setup of new utility systems, offering opportunities for specialization in trenching, piping, or electrical wiring. Advancement in maintenance often leads to supervisory or technical specialist positions, while installation careers can progress into project management or estimator roles within utility companies.

Industry Challenges and Future Trends

Utility maintenance faces challenges such as aging infrastructure, increasing demand for reliability, and the need for rapid response to outages, requiring advanced monitoring technologies and predictive analytics. Utility installation encounters difficulties including regulatory compliance, environmental considerations, and integration of renewable energy sources, demanding innovative construction methods and smart grid integration. Future trends emphasize automation, digital twins, and AI-driven optimization to enhance both maintenance efficiency and installation precision in the utility sector.

Utility Maintenance vs Utility Installation Infographic

jobdiv.com

jobdiv.com