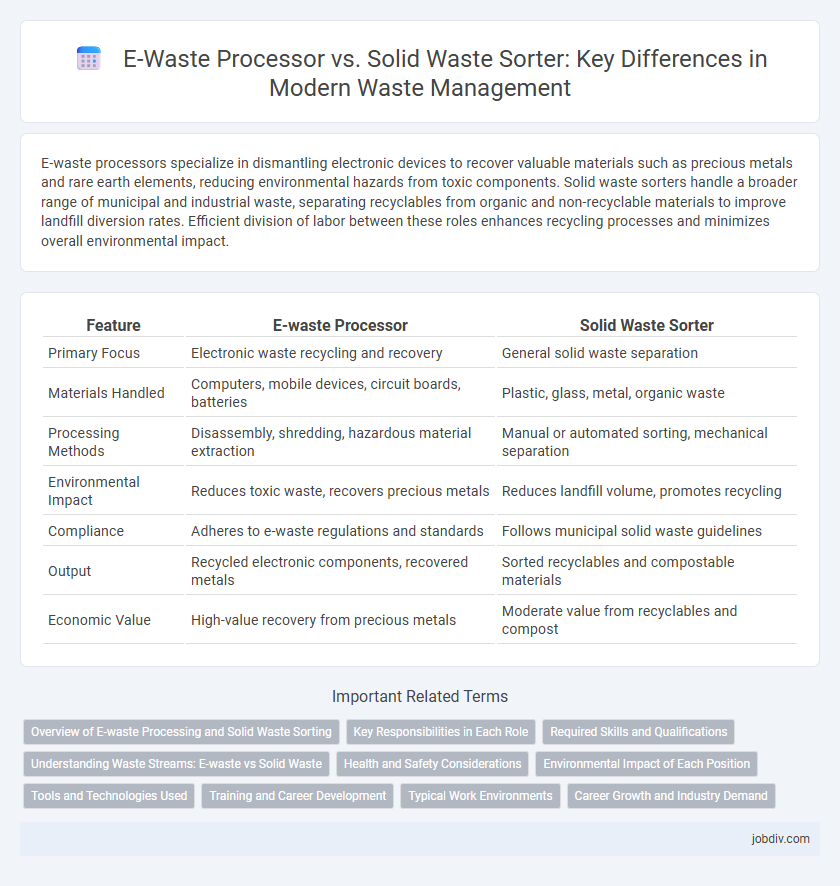

E-waste processors specialize in dismantling electronic devices to recover valuable materials such as precious metals and rare earth elements, reducing environmental hazards from toxic components. Solid waste sorters handle a broader range of municipal and industrial waste, separating recyclables from organic and non-recyclable materials to improve landfill diversion rates. Efficient division of labor between these roles enhances recycling processes and minimizes overall environmental impact.

Table of Comparison

| Feature | E-waste Processor | Solid Waste Sorter |

|---|---|---|

| Primary Focus | Electronic waste recycling and recovery | General solid waste separation |

| Materials Handled | Computers, mobile devices, circuit boards, batteries | Plastic, glass, metal, organic waste |

| Processing Methods | Disassembly, shredding, hazardous material extraction | Manual or automated sorting, mechanical separation |

| Environmental Impact | Reduces toxic waste, recovers precious metals | Reduces landfill volume, promotes recycling |

| Compliance | Adheres to e-waste regulations and standards | Follows municipal solid waste guidelines |

| Output | Recycled electronic components, recovered metals | Sorted recyclables and compostable materials |

| Economic Value | High-value recovery from precious metals | Moderate value from recyclables and compost |

Overview of E-waste Processing and Solid Waste Sorting

E-waste processing involves dismantling, shredding, and recovering valuable metals from discarded electronic devices, emphasizing the extraction of precious metals like gold, silver, and copper to reduce environmental hazards. Solid waste sorting categorizes municipal and industrial refuse into recyclables, organics, and landfill, improving recycling efficiency and reducing landfill volumes. Both processes are critical for sustainable waste management, with e-waste processing targeting electronic components while solid waste sorting addresses broader waste streams.

Key Responsibilities in Each Role

E-waste processors specialize in dismantling and recycling electronic devices, ensuring the recovery of valuable metals like gold and copper while safely handling hazardous components such as batteries and circuit boards. Solid waste sorters focus on separating recyclable materials like plastics, paper, and metals from general waste to facilitate efficient recycling processes and reduce landfill volumes. Both roles require knowledge of waste classification and adherence to environmental safety protocols but differ in the types of materials handled and processing techniques used.

Required Skills and Qualifications

E-waste processors require specialized knowledge in electronics dismantling, hazardous materials handling, and compliance with environmental regulations, alongside technical skills in circuit board and battery separation. Solid waste sorters need proficiency in manual sorting techniques, an understanding of recyclable materials, and adherence to safety protocols related to general waste handling. Both roles demand physical stamina, attention to detail, and a commitment to workplace safety standards within waste management operations.

Understanding Waste Streams: E-waste vs Solid Waste

E-waste processors specialize in handling electronic waste streams composed of discarded computers, smartphones, and other electronic devices, focusing on recovering valuable metals and components while safely managing hazardous materials. Solid waste sorters manage a broader spectrum of waste including organic material, plastics, metals, and paper, separating recyclables from landfill-bound refuse to optimize material recovery and reduce environmental impact. Understanding the distinct composition and hazards of e-waste versus solid waste is critical for applying appropriate sorting techniques and meeting regulatory compliance in waste management operations.

Health and Safety Considerations

E-waste processors face higher health risks due to exposure to hazardous substances like lead, mercury, and cadmium found in electronic components, requiring specialized protective equipment and ventilation systems to minimize toxic inhalation and skin contact. Solid waste sorters primarily handle mixed materials with variable contamination but encounter fewer chemical hazards, focusing instead on physical injury prevention through ergonomic tools, safety training, and personal protective gear such as gloves and masks. Implementing strict occupational health protocols is critical in both roles to reduce long-term respiratory and dermatological conditions and ensure worker safety in waste management environments.

Environmental Impact of Each Position

E-waste processors specialize in dismantling and recycling electronic devices, significantly reducing hazardous material release such as lead and mercury into the environment. Solid waste sorters separate general waste streams to divert recyclables from landfills, mitigating pollution and conserving natural resources. While e-waste processors handle toxic substances with higher environmental risk, their work enables safe disposal and recovery of valuable materials, whereas solid waste sorters primarily prevent landfill overflow and reduce greenhouse gas emissions from organic waste decomposition.

Tools and Technologies Used

E-waste processors utilize advanced technologies such as automated shredders, magnetic separators, and optical sorters to efficiently dismantle and recover valuable metals from electronic devices. Solid waste sorters primarily rely on conveyor belts, manual picking stations, and mechanical screening equipment to separate recyclables like plastics, paper, and metals from general municipal waste. Integration of AI-driven systems and sensor-based sorting enhances accuracy and throughput in both e-waste and solid waste processing facilities.

Training and Career Development

E-waste processors require specialized training in electronic component identification, hazardous materials handling, and advanced recycling technologies to ensure safe and efficient disposal. Solid waste sorters typically undergo training that emphasizes manual sorting techniques, safety protocols, and environmental regulations to manage mixed waste streams effectively. Career development for e-waste processors often includes certifications in electronics recycling and opportunities to advance into technician or environmental compliance roles, while solid waste sorters may progress to supervisory positions or roles in waste management logistics.

Typical Work Environments

E-waste processors typically operate in specialized recycling facilities equipped with advanced machinery designed to dismantle and recover valuable materials from electronic devices. Solid waste sorters work primarily in municipal waste management centers or transfer stations where they manually or mechanically separate recyclable materials like plastics, metals, and paper from general refuse. Both roles require adherence to strict safety protocols, but e-waste processors often face additional hazards related to handling toxic substances such as lead and mercury.

Career Growth and Industry Demand

E-waste processors specialize in handling electronic waste, a rapidly growing sector driven by the surge in digital device consumption and regulatory mandates on hazardous materials, offering robust career growth and higher wages. Solid waste sorters focus on segregating municipal and industrial waste streams with steady demand linked to expanding urbanization and sustainability initiatives, though they often face limited advancement opportunities. Professionals in e-waste processing benefit from advanced technical skills and certifications, positioning them favorably in an industry experiencing exponential growth due to increased global electronic disposal rates.

E-waste Processor vs Solid Waste Sorter Infographic

jobdiv.com

jobdiv.com