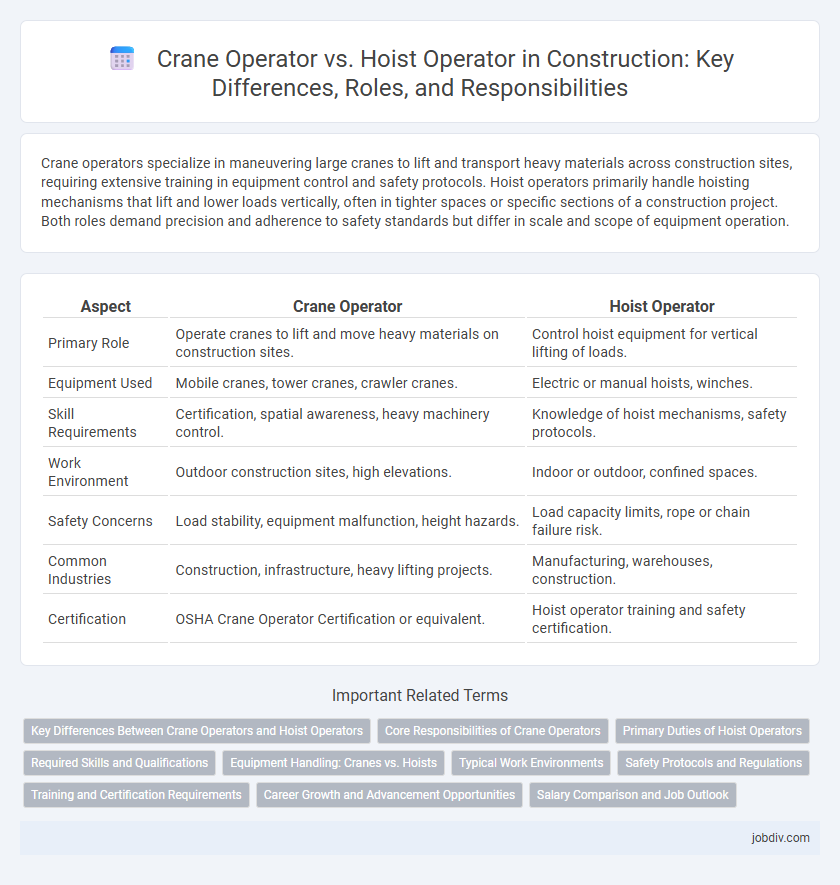

Crane operators specialize in maneuvering large cranes to lift and transport heavy materials across construction sites, requiring extensive training in equipment control and safety protocols. Hoist operators primarily handle hoisting mechanisms that lift and lower loads vertically, often in tighter spaces or specific sections of a construction project. Both roles demand precision and adherence to safety standards but differ in scale and scope of equipment operation.

Table of Comparison

| Aspect | Crane Operator | Hoist Operator |

|---|---|---|

| Primary Role | Operate cranes to lift and move heavy materials on construction sites. | Control hoist equipment for vertical lifting of loads. |

| Equipment Used | Mobile cranes, tower cranes, crawler cranes. | Electric or manual hoists, winches. |

| Skill Requirements | Certification, spatial awareness, heavy machinery control. | Knowledge of hoist mechanisms, safety protocols. |

| Work Environment | Outdoor construction sites, high elevations. | Indoor or outdoor, confined spaces. |

| Safety Concerns | Load stability, equipment malfunction, height hazards. | Load capacity limits, rope or chain failure risk. |

| Common Industries | Construction, infrastructure, heavy lifting projects. | Manufacturing, warehouses, construction. |

| Certification | OSHA Crane Operator Certification or equivalent. | Hoist operator training and safety certification. |

Key Differences Between Crane Operators and Hoist Operators

Crane operators control large, mobile lifting equipment to move heavy materials vertically and horizontally across construction sites, while hoist operators manage hoisting devices primarily designed for vertical lifting in confined or fixed locations. Crane operators require robust skills in maneuvering complex machinery with extended reach, often involving varying load capacities and site navigation, whereas hoist operators focus on precise load control within a limited range, frequently in indoor or scaffolded environments. The distinct operational scopes and equipment complexity differentiate crane operators' broader mobility and versatility from hoist operators' specialized lifting functions.

Core Responsibilities of Crane Operators

Crane operators are responsible for safely lifting, moving, and positioning heavy materials and equipment on construction sites using tower cranes, mobile cranes, or overhead cranes. They conduct pre-operation inspections, communicate with ground personnel, and adhere to safety protocols to prevent accidents and ensure project efficiency. Precision, situational awareness, and credentialed expertise are critical to managing load weights and coordinating with riggers during complex lifting tasks.

Primary Duties of Hoist Operators

Hoist operators are responsible for controlling and maneuvering hoists to lift, lower, and position materials or equipment safely on construction sites. They ensure precise load handling by monitoring hoist capacity, maintaining clear communication with signal persons, and adhering to safety protocols to prevent accidents. Their primary duties include inspecting hoist machinery for defects, performing routine maintenance, and coordinating with other operators to facilitate efficient material movement.

Required Skills and Qualifications

Crane operators must possess certifications such as NCCCO or state-specific licenses and demonstrate proficiency in operating various crane types, understanding load charts, and executing precise load handling. Hoist operators require knowledge of rigging techniques, safety protocols, and mechanical skills to manage hoist systems effectively, often needing certifications in rigging and hoisting safety. Both roles demand strong spatial awareness, communication skills, and adherence to OSHA regulations to ensure safe and efficient lifting operations on construction sites.

Equipment Handling: Cranes vs. Hoists

Crane operators specialize in maneuvering large cranes to lift, move, and position heavy materials across construction sites, utilizing equipment like tower cranes, mobile cranes, and overhead cranes. Hoist operators manage hoisting devices that lift or lower loads vertically, often using chain or wire rope hoists designed for precise material placement in confined or indoor spaces. Understanding the distinct operational controls and safety protocols for cranes versus hoists is essential for optimal equipment handling and site efficiency in construction projects.

Typical Work Environments

Crane operators typically work on large construction sites, shipyards, or industrial facilities where heavy lifting and precise load placement are required. Hoist operators often work in smaller-scale environments such as warehouses, manufacturing plants, or maintenance areas, focusing on lifting materials vertically within confined spaces. Both roles demand a high level of safety awareness and coordination with site personnel to ensure efficient and secure material handling.

Safety Protocols and Regulations

Crane operators and hoist operators must adhere to strict safety protocols and regulations outlined by OSHA and ANSI standards to prevent accidents on construction sites. Crane operators require certification through programs like NCCCO, emphasizing load capacity awareness and swing radius control, while hoist operators focus on load stability and proper attachment techniques. Both roles demand continuous safety training, regular equipment inspections, and compliance with site-specific hazard assessments to ensure operational safety.

Training and Certification Requirements

Crane operators require specialized training and certification from accredited organizations such as NCCCO or CIC, focusing on safe crane operation, load handling, and signaling protocols. Hoist operators undergo training emphasizing hoist-specific equipment operation and safety standards, often mandated by OSHA or local regulatory bodies. Certification for hoist operators may vary but commonly includes proficiency in rigging techniques and emergency procedures to ensure workplace safety.

Career Growth and Advancement Opportunities

Crane operators typically experience faster career growth due to their involvement in complex projects requiring specialized certifications and extensive technical skills. Hoist operators often find advancement opportunities within maintenance or supervisory roles, leveraging their expertise in equipment handling and safety protocols. Both paths offer growth, but crane operators generally access higher-paying positions and leadership roles in large-scale construction projects.

Salary Comparison and Job Outlook

Crane operators earn an average annual salary of $56,000, whereas hoist operators typically make around $45,000, reflecting a significant wage difference influenced by the complexity of equipment handled. Employment for crane operators is projected to grow by 6% through 2030 due to increased construction activity, while hoist operator jobs are expected to remain stable, with slower growth in industrial sectors. Demand for certified crane operators is rising, driven by stricter safety regulations and infrastructure developments, providing better long-term job security compared to hoist operators.

Crane Operator vs Hoist Operator Infographic

jobdiv.com

jobdiv.com