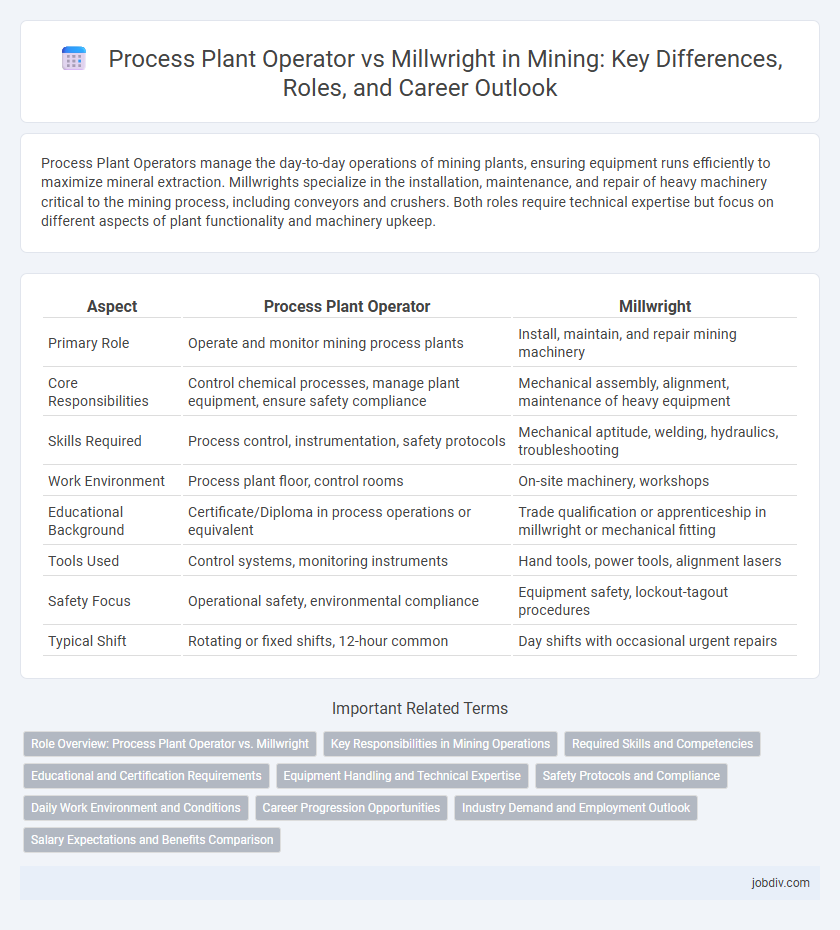

Process Plant Operators manage the day-to-day operations of mining plants, ensuring equipment runs efficiently to maximize mineral extraction. Millwrights specialize in the installation, maintenance, and repair of heavy machinery critical to the mining process, including conveyors and crushers. Both roles require technical expertise but focus on different aspects of plant functionality and machinery upkeep.

Table of Comparison

| Aspect | Process Plant Operator | Millwright |

|---|---|---|

| Primary Role | Operate and monitor mining process plants | Install, maintain, and repair mining machinery |

| Core Responsibilities | Control chemical processes, manage plant equipment, ensure safety compliance | Mechanical assembly, alignment, maintenance of heavy equipment |

| Skills Required | Process control, instrumentation, safety protocols | Mechanical aptitude, welding, hydraulics, troubleshooting |

| Work Environment | Process plant floor, control rooms | On-site machinery, workshops |

| Educational Background | Certificate/Diploma in process operations or equivalent | Trade qualification or apprenticeship in millwright or mechanical fitting |

| Tools Used | Control systems, monitoring instruments | Hand tools, power tools, alignment lasers |

| Safety Focus | Operational safety, environmental compliance | Equipment safety, lockout-tagout procedures |

| Typical Shift | Rotating or fixed shifts, 12-hour common | Day shifts with occasional urgent repairs |

Role Overview: Process Plant Operator vs. Millwright

Process Plant Operators manage and monitor equipment in mining facilities to ensure efficient mineral processing, controlling variables such as flow rates, pressure, and temperature for optimal output. Millwrights specialize in installing, maintaining, and repairing heavy machinery used in mining operations, including conveyors, crushers, and grinding mills, ensuring minimal downtime. Both roles are critical for operational continuity, with Process Plant Operators focusing on operational control and Millwrights on mechanical integrity.

Key Responsibilities in Mining Operations

Process Plant Operators manage the control and optimization of mining equipment and chemical processes to ensure efficient mineral extraction and processing. Millwrights specialize in installing, maintaining, and repairing heavy machinery and mechanical systems crucial to the continuous operation of mining plants. Both roles are essential for maximizing equipment uptime, safety compliance, and production output in mining operations.

Required Skills and Competencies

Process Plant Operators must have strong knowledge of chemical processes, mechanical systems, and safety regulations, with skills in monitoring equipment and controlling process parameters. Millwrights require advanced mechanical proficiency, including precision in assembling, installing, and maintaining heavy machinery, along with problem-solving abilities for troubleshooting complex equipment. Both roles demand attention to detail, physical stamina, and adherence to safety standards, but Process Plant Operators emphasize process control, while Millwrights specialize in mechanical repair and installation.

Educational and Certification Requirements

Process Plant Operators typically require a high school diploma or equivalent, with many employers favoring certifications such as the Certificate III in Process Operations to demonstrate proficiency in plant control systems and safety protocols. Millwrights generally need a technical diploma or an apprenticeship in industrial mechanics, often supported by trade certifications like a Red Seal endorsement, reflecting their expertise in machinery installation, maintenance, and repair. Both roles may require additional site-specific training and safety certifications such as first aid or confined space entry to comply with mining industry standards.

Equipment Handling and Technical Expertise

Process Plant Operators in mining are responsible for monitoring and controlling equipment to ensure continuous and efficient operation, requiring expertise in process control systems and equipment diagnostics. Millwrights specialize in the installation, maintenance, and repair of heavy machinery, demonstrating advanced mechanical skills and knowledge of hydraulic, pneumatic, and electrical systems. Both roles demand technical proficiency, but Process Plant Operators focus more on operational control and data analysis, while Millwrights emphasize hands-on equipment handling and mechanical troubleshooting.

Safety Protocols and Compliance

Process Plant Operators and Millwrights both adhere to strict safety protocols to mitigate risks in mining environments, emphasizing the use of personal protective equipment (PPE) and comprehensive hazard assessments. Operators focus on monitoring and controlling plant systems to maintain regulatory compliance with OSHA and MSHA standards, while Millwrights prioritize safe installation, maintenance, and repair of machinery to prevent equipment-related accidents. Both roles undergo regular safety training and audits to ensure alignment with industry safety procedures and environmental regulations.

Daily Work Environment and Conditions

Process Plant Operators in mining typically work in control rooms or plant floors, monitoring equipment and ensuring the smooth operation of processing systems under variable temperature and noise levels. Millwrights are often exposed to more physically demanding conditions, performing mechanical maintenance and installations directly on heavy machinery and equipment, frequently outdoors or in confined spaces with exposure to dust and vibrations. Both roles require adherence to strict safety protocols, with Process Plant Operators facing sedentary, high-concentration tasks and Millwrights engaging in hands-on, labor-intensive work environments.

Career Progression Opportunities

Process Plant Operators in mining typically advance by gaining expertise in plant control systems, moving towards supervisory roles or specialized technical positions such as process engineering. Millwrights have career progression opportunities that often involve becoming lead millwrights, maintenance supervisors, or transitioning into instrumentation and electrical trades within plant operations. Both career paths benefit from continuous training and certifications, but Process Plant Operators tend to progress into operational management roles, while Millwrights focus on technical leadership and maintenance strategy development.

Industry Demand and Employment Outlook

The mining industry shows strong demand for Process Plant Operators due to increasing automation and the need for skilled operators to manage complex processing equipment efficiently. Millwrights are also in high demand because of their expertise in installing, maintaining, and repairing heavy machinery critical to mining operations, with employment growth projected to remain steady. Both roles offer significant employment opportunities, but Process Plant Operators may experience faster growth linked to advancements in mineral processing technologies.

Salary Expectations and Benefits Comparison

Process Plant Operators in mining typically earn an average annual salary ranging from $65,000 to $90,000, with benefits including performance bonuses, health coverage, and retirement plans. Millwrights command a slightly higher salary bracket, often between $75,000 and $100,000 per year, reflecting their specialized skills in equipment maintenance, alongside enhanced benefits such as overtime pay, apprenticeships, and certification sponsorships. Both roles offer job stability and opportunities for wage increases tied to experience and certifications within the mining industry.

Process Plant Operator vs Millwright Infographic

jobdiv.com

jobdiv.com