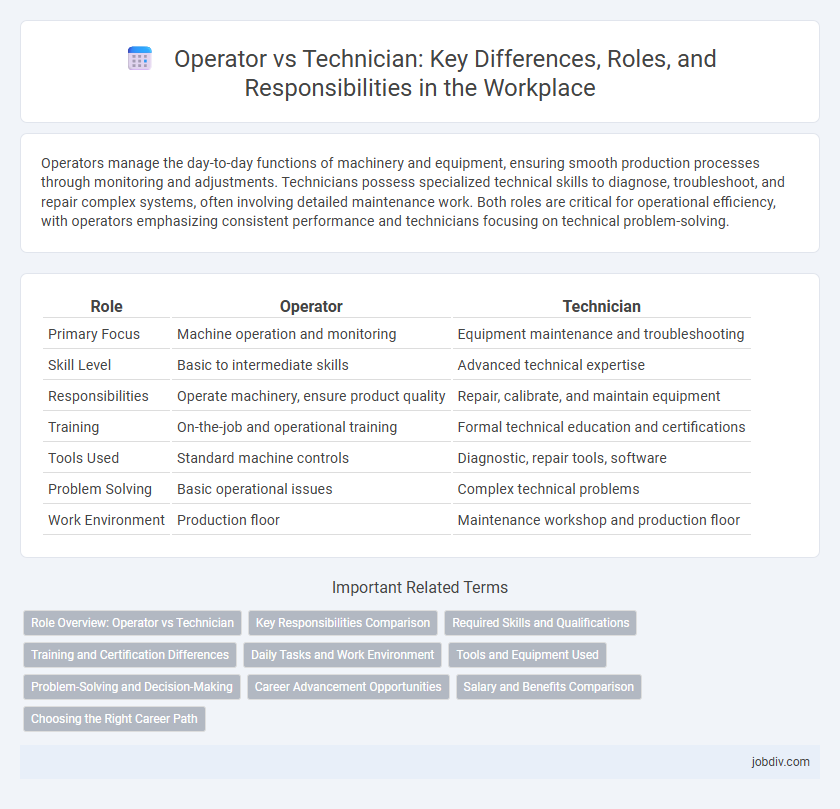

Operators manage the day-to-day functions of machinery and equipment, ensuring smooth production processes through monitoring and adjustments. Technicians possess specialized technical skills to diagnose, troubleshoot, and repair complex systems, often involving detailed maintenance work. Both roles are critical for operational efficiency, with operators emphasizing consistent performance and technicians focusing on technical problem-solving.

Table of Comparison

| Role | Operator | Technician |

|---|---|---|

| Primary Focus | Machine operation and monitoring | Equipment maintenance and troubleshooting |

| Skill Level | Basic to intermediate skills | Advanced technical expertise |

| Responsibilities | Operate machinery, ensure product quality | Repair, calibrate, and maintain equipment |

| Training | On-the-job and operational training | Formal technical education and certifications |

| Tools Used | Standard machine controls | Diagnostic, repair tools, software |

| Problem Solving | Basic operational issues | Complex technical problems |

| Work Environment | Production floor | Maintenance workshop and production floor |

Role Overview: Operator vs Technician

Operators manage and monitor the performance of machinery or systems, ensuring smooth and efficient production processes. Technicians diagnose, troubleshoot, and repair equipment, applying technical expertise to maintain operational functionality. The operator's role centers on system control and real-time adjustments, while the technician emphasizes maintenance and problem resolution.

Key Responsibilities Comparison

Operators primarily manage machinery operation, ensuring production processes run smoothly and efficiently, while technicians specialize in maintaining, troubleshooting, and repairing equipment to prevent downtime. Operators monitor system performance and adhere to safety protocols, whereas technicians conduct diagnostic tests and implement technical solutions to complex mechanical issues. Both roles require technical expertise but differ in focus; operators emphasize operational continuity, and technicians prioritize equipment functionality and maintenance.

Required Skills and Qualifications

Operators require strong machine operation skills, attention to detail, and basic troubleshooting abilities, often needing a high school diploma or equivalent. Technicians demand advanced technical knowledge, including diagnostic skills, proficiency with specialized tools, and usually hold certifications or an associate degree in their field. Both roles emphasize safety protocols, but technicians typically handle more complex systems and maintenance tasks.

Training and Certification Differences

Operators typically require training centered on equipment operation and safety protocols, often completed through on-the-job instruction and basic certifications. Technicians receive more advanced education involving technical diagnostics, maintenance, and repair, usually necessitating formal certification programs or degrees. Certification for technicians often includes specialized credentials such as ASE or HVAC certificates, reflecting a deeper proficiency level compared to operator qualifications.

Daily Tasks and Work Environment

Operators primarily manage and control machinery or production lines, monitoring systems to ensure efficient operation and troubleshoot minor issues, often working in fast-paced manufacturing or industrial environments. Technicians perform more specialized tasks, such as diagnosing complex problems, conducting repairs, and maintaining equipment, requiring technical expertise and hands-on skills in diverse settings like laboratories, field sites, or workshops. Both roles demand adherence to safety protocols, but technicians generally engage in detailed documentation and calibration activities as part of their daily responsibilities.

Tools and Equipment Used

Operators primarily use specialized machinery and control panels to manage production processes, relying on tools like PLCs, CNC machines, and automated systems for efficient operation. Technicians focus on diagnostic instruments, calibration devices, and repair tools such as multimeters, oscilloscopes, and soldering equipment to maintain and troubleshoot equipment performance. Both roles require proficiency with industry-specific software and hardware to ensure seamless equipment functionality and process optimization.

Problem-Solving and Decision-Making

Operators primarily follow established procedures and protocols to maintain equipment functionality, relying on routine problem-solving methods for immediate issues. Technicians possess advanced diagnostic skills and deeper technical knowledge, enabling them to analyze complex malfunctions and implement long-term solutions. Effective decision-making by technicians often involves interpreting technical data and troubleshooting beyond standard operating conditions, enhancing system reliability.

Career Advancement Opportunities

Operators often begin their careers handling routine tasks, providing a foundation for technical skill development, while technicians usually possess specialized knowledge that enables them to take on complex troubleshooting and maintenance roles. Career advancement for operators typically involves gaining certifications and experience to transition into technician or supervisory positions, whereas technicians can progress into senior technical roles, engineering, or management. Companies increasingly value cross-training, allowing operators to advance by acquiring technical expertise, thus broadening their career opportunities within industrial and manufacturing sectors.

Salary and Benefits Comparison

Technicians generally earn higher salaries than operators due to their advanced technical skills and specialized training, with median annual wages often 15-25% above operator pay. Benefits packages for technicians frequently include enhanced healthcare options, retirement plans, and opportunities for professional development, reflecting their heightened responsibilities. Employers value technicians for their expertise, resulting in better compensation and more comprehensive benefits compared to operators.

Choosing the Right Career Path

Choosing the right career path between an operator and a technician depends on individual skills and long-term goals, as operators primarily manage and control machinery while technicians are responsible for troubleshooting and maintenance. Operators often require strong attention to detail and adherence to protocols, whereas technicians need advanced technical knowledge and problem-solving abilities. Understanding industry demands, salary prospects, and certification requirements can help professionals make an informed decision aligned with their career aspirations.

Operator vs Technician Infographic

jobdiv.com

jobdiv.com