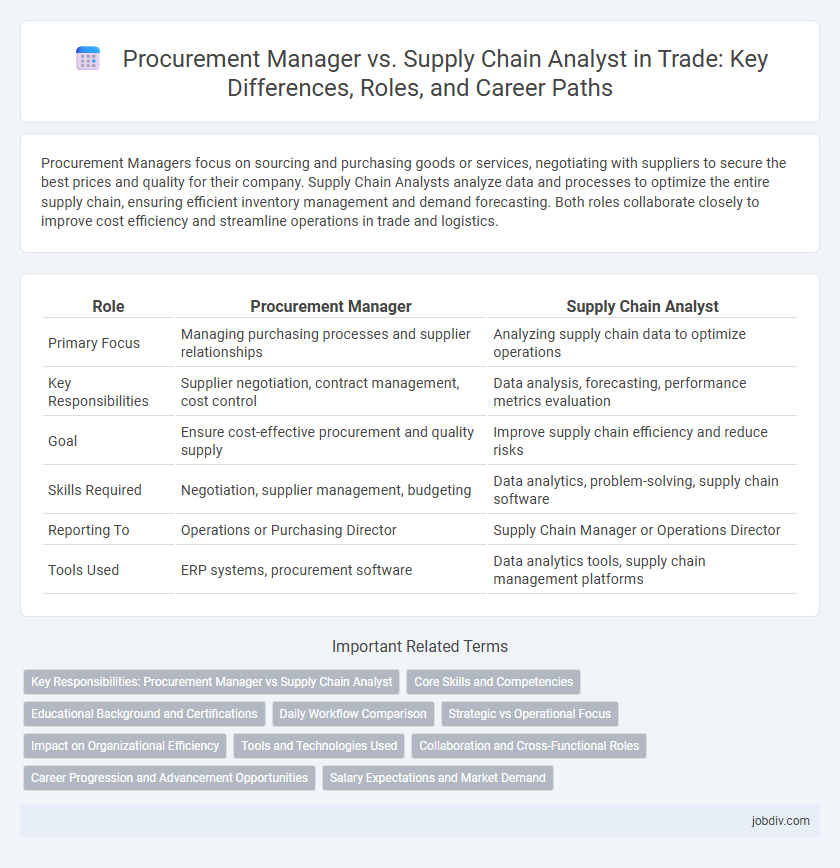

Procurement Managers focus on sourcing and purchasing goods or services, negotiating with suppliers to secure the best prices and quality for their company. Supply Chain Analysts analyze data and processes to optimize the entire supply chain, ensuring efficient inventory management and demand forecasting. Both roles collaborate closely to improve cost efficiency and streamline operations in trade and logistics.

Table of Comparison

| Role | Procurement Manager | Supply Chain Analyst |

|---|---|---|

| Primary Focus | Managing purchasing processes and supplier relationships | Analyzing supply chain data to optimize operations |

| Key Responsibilities | Supplier negotiation, contract management, cost control | Data analysis, forecasting, performance metrics evaluation |

| Goal | Ensure cost-effective procurement and quality supply | Improve supply chain efficiency and reduce risks |

| Skills Required | Negotiation, supplier management, budgeting | Data analytics, problem-solving, supply chain software |

| Reporting To | Operations or Purchasing Director | Supply Chain Manager or Operations Director |

| Tools Used | ERP systems, procurement software | Data analytics tools, supply chain management platforms |

Key Responsibilities: Procurement Manager vs Supply Chain Analyst

Procurement Managers oversee vendor selection, contract negotiations, and purchasing strategies to ensure cost-effective acquisition of goods and services. Supply Chain Analysts focus on data analysis, demand forecasting, and process optimization to enhance supply chain efficiency and reduce operational costs. Both roles collaborate closely to align procurement activities with broader supply chain objectives, driving organizational performance.

Core Skills and Competencies

Procurement Managers excel in negotiation, contract management, and supplier relationship expertise, ensuring cost efficiency and timely delivery of goods. Supply Chain Analysts focus on data analysis, demand forecasting, and inventory optimization to enhance overall supply chain performance. Both roles require strategic thinking, problem-solving skills, and proficiency in supply chain software such as SAP or Oracle.

Educational Background and Certifications

Procurement Managers typically hold a bachelor's degree in business administration, supply chain management, or logistics and often pursue certifications such as Certified Professional in Supply Management (CPSM) or Certified Purchasing Manager (CPM) to enhance strategic sourcing skills. Supply Chain Analysts generally have a strong foundation in data analysis, often earning degrees in industrial engineering, statistics, or supply chain analytics, complemented by certifications like Certified Supply Chain Professional (CSCP) or Six Sigma to optimize operational efficiency. Both roles require continuous education in procurement software, data analysis tools, and industry-specific standards to maintain competitive expertise in trade and supply chain management.

Daily Workflow Comparison

Procurement Managers focus on sourcing goods, negotiating with suppliers, and managing purchase orders to ensure timely delivery and cost efficiency. Supply Chain Analysts analyze data, track inventory levels, and optimize supply chain processes to improve overall operational performance. Both roles collaborate closely but emphasize different aspects of procurement and supply chain management for seamless trade operations.

Strategic vs Operational Focus

Procurement Managers concentrate on strategic sourcing, supplier negotiations, and contract management to optimize cost efficiency and long-term supplier relationships. Supply Chain Analysts focus on operational data analysis, demand forecasting, and inventory optimization to ensure seamless supply chain execution. Both roles are crucial but differ in their emphasis on strategic planning versus day-to-day operational management within trade operations.

Impact on Organizational Efficiency

Procurement Managers streamline vendor negotiations and contract management, directly reducing costs and ensuring timely delivery of materials, which enhances organizational efficiency. Supply Chain Analysts leverage data-driven insights to optimize inventory levels and forecast demand, minimizing waste and improving overall supply chain performance. Together, their roles drive cost savings and operational agility, significantly impacting organizational efficiency in trade-focused companies.

Tools and Technologies Used

Procurement Managers primarily utilize e-procurement platforms, supplier relationship management (SRM) software, and contract management tools to streamline purchasing processes and ensure compliance. Supply Chain Analysts rely heavily on advanced data analytics software, enterprise resource planning (ERP) systems, and supply chain visualization tools to optimize inventory levels and forecast demand. Both roles leverage automation technologies and cloud-based solutions, yet Procurement Managers focus more on supplier engagement, whereas Supply Chain Analysts emphasize data-driven decision-making.

Collaboration and Cross-Functional Roles

Procurement Managers and Supply Chain Analysts collaborate closely to optimize sourcing strategies and enhance operational efficiency. Procurement Managers focus on supplier negotiations and contract management, while Supply Chain Analysts analyze data to forecast demand and identify cost-saving opportunities. Their cross-functional roles integrate supplier relationships with supply chain analytics, driving informed decision-making and seamless end-to-end supply chain performance.

Career Progression and Advancement Opportunities

Procurement Managers oversee vendor relationships and negotiate contracts, providing a strong foundation for advancing into senior procurement or supply chain leadership roles such as Director of Procurement. Supply Chain Analysts analyze data to optimize logistics and inventory, offering pathways to careers in supply chain management or operations strategy. Both roles offer robust career progression, with Procurement Managers often moving towards strategic sourcing and supplier management, while Supply Chain Analysts transition into broader analytical and decision-making positions within supply chain networks.

Salary Expectations and Market Demand

Procurement Managers typically command higher salaries, averaging $90,000 to $120,000 annually, driven by their strategic role in vendor negotiations and cost management. Supply Chain Analysts earn between $65,000 and $85,000, reflecting strong demand for data-driven optimization skills in logistics and inventory control. Market trends indicate rising demand for Supply Chain Analysts due to increased reliance on analytics, while Procurement Managers remain essential for contract management and supplier relations.

Procurement Manager vs Supply Chain Analyst Infographic

jobdiv.com

jobdiv.com