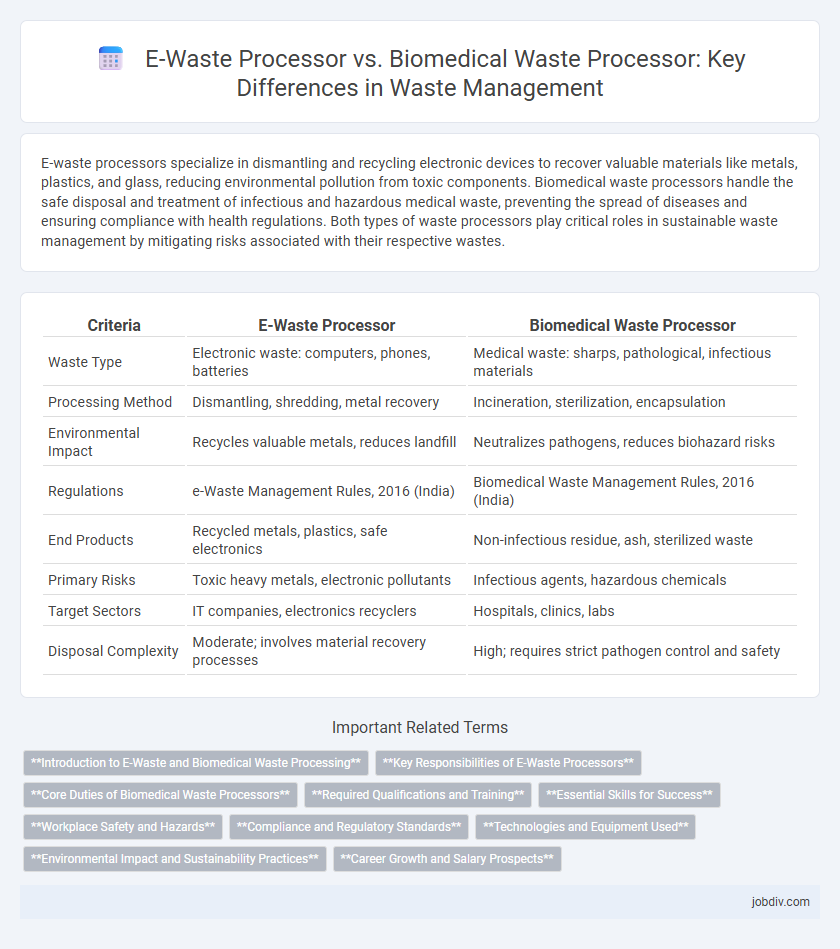

E-waste processors specialize in dismantling and recycling electronic devices to recover valuable materials like metals, plastics, and glass, reducing environmental pollution from toxic components. Biomedical waste processors handle the safe disposal and treatment of infectious and hazardous medical waste, preventing the spread of diseases and ensuring compliance with health regulations. Both types of waste processors play critical roles in sustainable waste management by mitigating risks associated with their respective wastes.

Table of Comparison

| Criteria | E-Waste Processor | Biomedical Waste Processor |

|---|---|---|

| Waste Type | Electronic waste: computers, phones, batteries | Medical waste: sharps, pathological, infectious materials |

| Processing Method | Dismantling, shredding, metal recovery | Incineration, sterilization, encapsulation |

| Environmental Impact | Recycles valuable metals, reduces landfill | Neutralizes pathogens, reduces biohazard risks |

| Regulations | e-Waste Management Rules, 2016 (India) | Biomedical Waste Management Rules, 2016 (India) |

| End Products | Recycled metals, plastics, safe electronics | Non-infectious residue, ash, sterilized waste |

| Primary Risks | Toxic heavy metals, electronic pollutants | Infectious agents, hazardous chemicals |

| Target Sectors | IT companies, electronics recyclers | Hospitals, clinics, labs |

| Disposal Complexity | Moderate; involves material recovery processes | High; requires strict pathogen control and safety |

Introduction to E-Waste and Biomedical Waste Processing

E-waste processing involves the collection, dismantling, and recycling of electronic devices such as computers, smartphones, and televisions to recover valuable metals and prevent environmental contamination. Biomedical waste processing handles hazardous materials generated from healthcare activities, including sharps, pathological waste, and pharmaceutical residues, requiring specialized treatment like autoclaving or incineration to ensure safety. Both waste types demand strict regulatory compliance and advanced technology to mitigate health risks and promote sustainable waste management.

Key Responsibilities of E-Waste Processors

E-waste processors specialize in the safe disassembly, recycling, and disposal of electronic devices, ensuring hazardous materials like lead, mercury, and cadmium are properly managed to prevent environmental contamination. They are responsible for recovering valuable metals such as gold, silver, and copper, adhering to regulatory compliance, and promoting sustainable practices in electronics waste management. Unlike biomedical waste processors, who focus on biohazard containment and sterilization, e-waste processors emphasize resource recovery and electronic component reuse.

Core Duties of Biomedical Waste Processors

Biomedical waste processors specialize in safely handling, segregating, and treating hazardous medical waste to prevent contamination and disease transmission. They employ methods such as autoclaving, incineration, and chemical disinfection to neutralize infectious materials from hospitals, clinics, and laboratories. Compliance with stringent regulations and proper documentation ensures environmental safety and public health protection throughout the waste management cycle.

Required Qualifications and Training

E-waste processors require qualifications in electronics, information technology, or environmental science, combined with specialized training in hazardous material handling and data protection protocols. Biomedical waste processors must possess certifications in medical waste management, often including training in infection control, biosafety measures, and regulatory compliance specific to healthcare waste. Both roles demand continuous education to stay updated on evolving disposal technologies and environmental regulations.

Essential Skills for Success

E-waste processors require advanced technical skills in electronics dismantling, hazardous material handling, and data security to safely recycle and repurpose electronic components. Biomedical waste processors must possess expertise in infection control, chemical treatment protocols, and regulatory compliance to manage and dispose of biohazards safely. Both roles demand strong attention to detail, knowledge of environmental laws, and proficiency in waste segregation to ensure safe and efficient processing.

Workplace Safety and Hazards

E-waste processors face significant risks from exposure to toxic heavy metals like lead, mercury, and cadmium, necessitating strict use of personal protective equipment and specialized ventilation systems to prevent inhalation and skin contact. Biomedical waste processors encounter hazards from infectious pathogens and sharp objects, requiring rigorous sterilization protocols, needle-stick prevention measures, and biohazard containment to ensure workplace safety. Both sectors must implement comprehensive safety training and emergency response plans to mitigate chemical, biological, and physical hazards inherent in their waste handling processes.

Compliance and Regulatory Standards

E-waste processors comply with regulations such as the WEEE Directive, e-Stewards standards, and local electronic waste disposal laws to ensure safe handling and recycling of hazardous components. Biomedical waste processors adhere to stringent standards like the Bio-medical Waste Management Rules (India), OSHA regulations, and WHO guidelines to manage infectious and hazardous medical waste safely. Both industries prioritize compliance to protect public health and the environment, but biomedical waste processing demands stricter sterilization and disposal protocols due to the biological risks involved.

Technologies and Equipment Used

E-waste processors utilize advanced technologies such as automated shredders, eddy current separators, and high-temperature smelters to recover valuable metals and safely dismantle electronic components. Biomedical waste processors rely on autoclaves, microwave treatment systems, and chemical disinfectants to sterilize and deactivate infectious materials, ensuring safe disposal. Both industries deploy specialized equipment tailored to handle the unique hazards of their respective waste streams efficiently and in compliance with environmental regulations.

Environmental Impact and Sustainability Practices

E-Waste processors implement advanced recycling techniques to recover valuable metals while minimizing hazardous substance release, promoting circular economy principles and reducing landfill burden. Biomedical waste processors focus on safe sterilization and disposal methods, such as autoclaving and incineration with emission controls, to prevent biohazard contamination and environmental pollution. Both systems emphasize regulatory compliance and continuous improvement in sustainability practices to mitigate ecological footprints and protect public health.

Career Growth and Salary Prospects

E-waste processors benefit from rapidly growing career opportunities driven by increasing electronic consumption and regulatory emphasis on sustainable recycling, with average salaries ranging from $45,000 to $75,000 annually depending on expertise and location. Biomedical waste processors experience steady demand due to stringent healthcare waste management protocols, offering salaries typically between $40,000 and $70,000, with upward growth linked to specialization in hazardous waste treatment. Both fields present promising career trajectories, but e-waste processing tends to offer faster expansion and higher earning potential due to technological advancements and global electronic waste challenges.

E-Waste Processor vs Biomedical Waste Processor Infographic

jobdiv.com

jobdiv.com