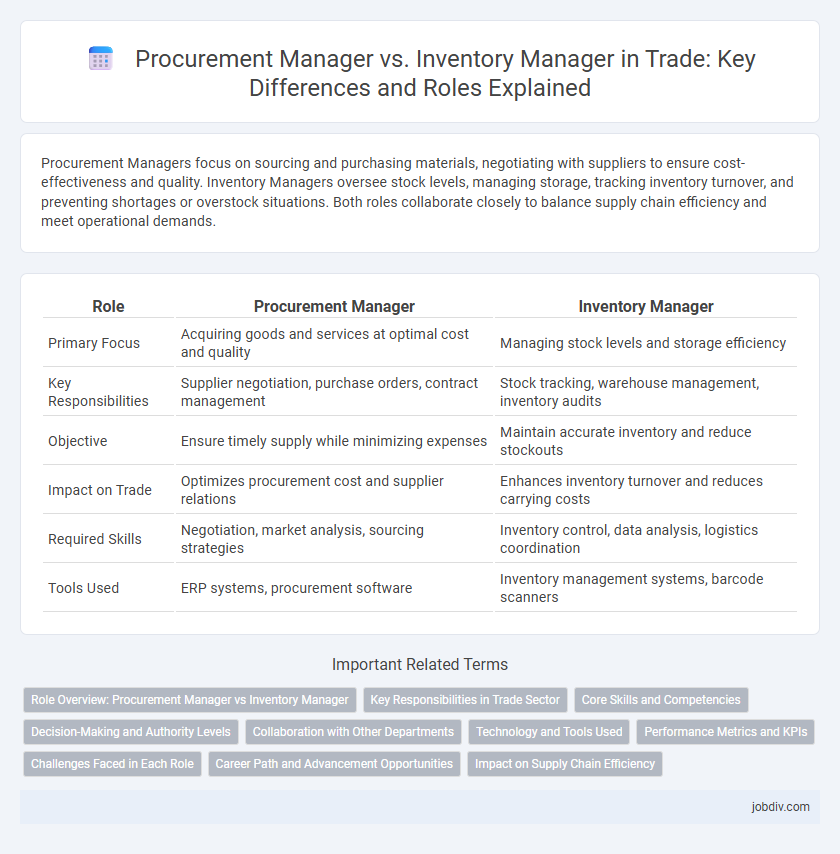

Procurement Managers focus on sourcing and purchasing materials, negotiating with suppliers to ensure cost-effectiveness and quality. Inventory Managers oversee stock levels, managing storage, tracking inventory turnover, and preventing shortages or overstock situations. Both roles collaborate closely to balance supply chain efficiency and meet operational demands.

Table of Comparison

| Role | Procurement Manager | Inventory Manager |

|---|---|---|

| Primary Focus | Acquiring goods and services at optimal cost and quality | Managing stock levels and storage efficiency |

| Key Responsibilities | Supplier negotiation, purchase orders, contract management | Stock tracking, warehouse management, inventory audits |

| Objective | Ensure timely supply while minimizing expenses | Maintain accurate inventory and reduce stockouts |

| Impact on Trade | Optimizes procurement cost and supplier relations | Enhances inventory turnover and reduces carrying costs |

| Required Skills | Negotiation, market analysis, sourcing strategies | Inventory control, data analysis, logistics coordination |

| Tools Used | ERP systems, procurement software | Inventory management systems, barcode scanners |

Role Overview: Procurement Manager vs Inventory Manager

A Procurement Manager oversees sourcing strategies, supplier negotiations, and contract management to ensure cost-effective purchasing and supply chain efficiency. An Inventory Manager focuses on stock control, demand forecasting, and inventory optimization to maintain balanced product availability and minimize carrying costs. Both roles collaborate to align procurement activities with inventory levels, enhancing operational flow and reducing supply disruptions.

Key Responsibilities in Trade Sector

Procurement Managers in the trade sector focus on sourcing suppliers, negotiating contracts, and ensuring cost-effective purchasing to maintain supply chain efficiency. Inventory Managers oversee stock levels, monitor inventory turnover, and implement strategies to optimize storage and reduce carrying costs. Both roles are critical for aligning supply with demand, minimizing operational disruptions, and maximizing profitability.

Core Skills and Competencies

Procurement Managers excel in supplier negotiation, contract management, and cost analysis, ensuring the acquisition of goods and services aligns with organizational budget and quality standards. Inventory Managers specialize in stock control, demand forecasting, and warehouse logistics to maintain optimal inventory levels and prevent stockouts or overstock situations. Both roles require strong analytical skills, proficiency in ERP systems, and effective communication to synchronize supply chain operations and support business continuity.

Decision-Making and Authority Levels

Procurement Managers primarily handle supplier selection, contract negotiations, and budget approvals, granting them high decision-making authority over purchasing strategies and vendor relationships. Inventory Managers focus on stock control, demand forecasting, and warehouse operations, exercising authority in optimizing inventory levels and ensuring product availability. Both roles require collaboration but maintain distinct decision-making domains aligned with procurement policies and inventory management systems.

Collaboration with Other Departments

Procurement Managers collaborate closely with Finance, Legal, and Quality Assurance teams to ensure supplier compliance and budget alignment, while Inventory Managers coordinate primarily with Sales, Warehouse, and Production departments to optimize stock levels and fulfill demand efficiently. Effective communication between Procurement and Inventory Managers is essential to synchronize purchase orders with inventory turnover rates, reducing stockouts and excess inventory. Streamlined collaboration across these roles enhances supply chain resilience and operational cost management in trade environments.

Technology and Tools Used

Procurement Managers utilize e-procurement platforms and supplier relationship management (SRM) software to streamline supplier selection, contract management, and purchase order automation. Inventory Managers rely heavily on warehouse management systems (WMS), barcode scanners, and real-time inventory tracking tools to optimize stock levels and reduce carrying costs. Both roles increasingly adopt integrated ERP systems that enhance collaboration, data accuracy, and decision-making efficiency across the supply chain.

Performance Metrics and KPIs

Procurement Managers are evaluated using KPIs such as cost savings, supplier lead time, and purchase order accuracy to ensure efficient sourcing and supplier performance. Inventory Managers focus on metrics like inventory turnover ratio, stock accuracy, and days of inventory on hand to optimize stock levels and reduce holding costs. Both roles rely on performance metrics that align with supply chain efficiency and cost management objectives to drive organizational success.

Challenges Faced in Each Role

Procurement Managers face challenges such as negotiating supplier contracts, managing cost fluctuations, and ensuring timely delivery while maintaining quality standards. Inventory Managers struggle with accurately forecasting demand, optimizing stock levels to prevent overstock or stockouts, and coordinating with logistics for efficient warehouse management. Both roles require balancing cost efficiency with operational continuity to support the overall supply chain effectiveness.

Career Path and Advancement Opportunities

Procurement Managers typically advance by gaining expertise in supplier negotiation, contract management, and strategic sourcing, leading to roles such as Procurement Director or Chief Supply Chain Officer. Inventory Managers often progress through mastering inventory control systems, demand forecasting, and warehouse management, with opportunities to become Inventory Control Directors or Operations Managers. Both career paths offer advancement into senior supply chain leadership positions, but the Procurement Manager role generally emphasizes external vendor relationships, while Inventory Managers focus on internal asset optimization.

Impact on Supply Chain Efficiency

A Procurement Manager ensures the acquisition of quality materials at optimal costs, directly affecting supplier relationships and production timelines. An Inventory Manager focuses on stock levels, demand forecasting, and storage efficiency to minimize holding costs and prevent stockouts. Together, their coordinated efforts enhance supply chain efficiency by balancing resource availability with operational needs.

Procurement Manager vs Inventory Manager Infographic

jobdiv.com

jobdiv.com