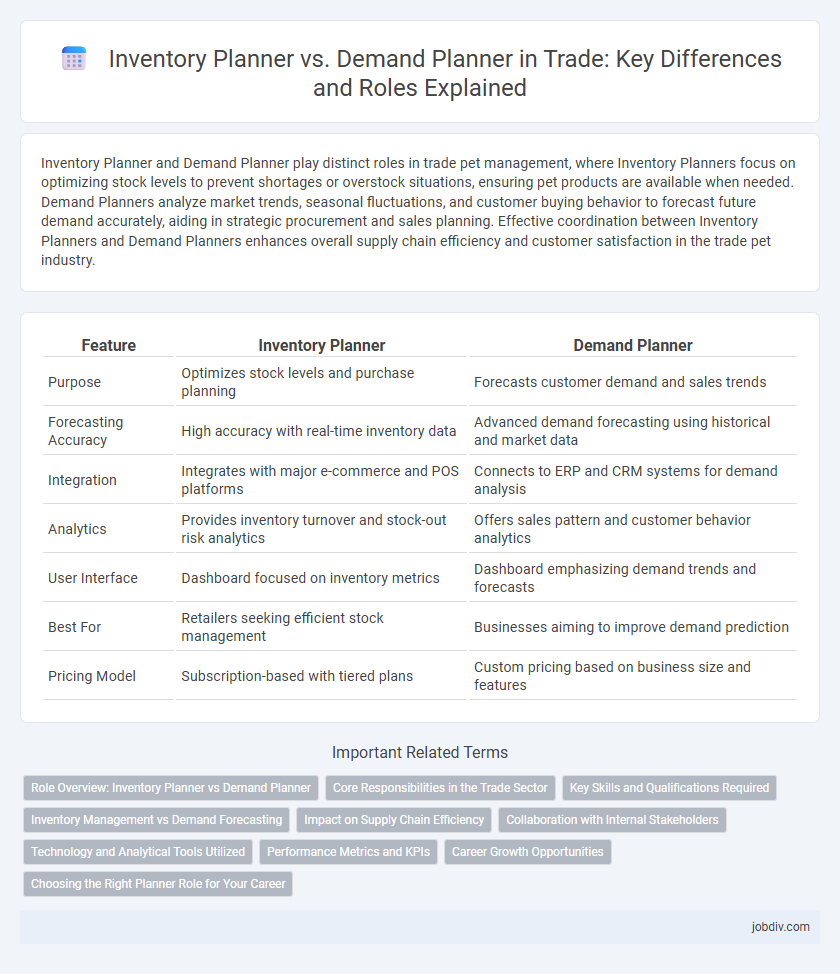

Inventory Planner and Demand Planner play distinct roles in trade pet management, where Inventory Planners focus on optimizing stock levels to prevent shortages or overstock situations, ensuring pet products are available when needed. Demand Planners analyze market trends, seasonal fluctuations, and customer buying behavior to forecast future demand accurately, aiding in strategic procurement and sales planning. Effective coordination between Inventory Planners and Demand Planners enhances overall supply chain efficiency and customer satisfaction in the trade pet industry.

Table of Comparison

| Feature | Inventory Planner | Demand Planner |

|---|---|---|

| Purpose | Optimizes stock levels and purchase planning | Forecasts customer demand and sales trends |

| Forecasting Accuracy | High accuracy with real-time inventory data | Advanced demand forecasting using historical and market data |

| Integration | Integrates with major e-commerce and POS platforms | Connects to ERP and CRM systems for demand analysis |

| Analytics | Provides inventory turnover and stock-out risk analytics | Offers sales pattern and customer behavior analytics |

| User Interface | Dashboard focused on inventory metrics | Dashboard emphasizing demand trends and forecasts |

| Best For | Retailers seeking efficient stock management | Businesses aiming to improve demand prediction |

| Pricing Model | Subscription-based with tiered plans | Custom pricing based on business size and features |

Role Overview: Inventory Planner vs Demand Planner

Inventory Planners focus on optimizing stock levels by analyzing sales data, supplier lead times, and storage capacities to prevent overstocking or stockouts. Demand Planners use forecasting models and market trends to predict customer demand, enabling precise production and procurement strategies. Both roles collaborate to balance supply chain efficiency and customer satisfaction, but Inventory Planners manage current stock while Demand Planners anticipate future needs.

Core Responsibilities in the Trade Sector

Inventory Planners in the trade sector focus on managing stock levels, optimizing reorder points, and minimizing holding costs to ensure product availability without overstocking. Demand Planners analyze market trends, customer demand patterns, and sales data to forecast future product needs accurately, enabling strategic procurement and sales alignment. Both roles collaborate to enhance supply chain efficiency, reduce stockouts, and improve customer satisfaction by balancing supply with market demand.

Key Skills and Qualifications Required

Inventory planners must excel in supply chain management, data analysis, and forecasting techniques to maintain optimal stock levels and minimize carrying costs. Demand planners require strong skills in statistical analysis, market trend evaluation, and collaborative communication to predict customer demand accurately and align production schedules. Both roles benefit from proficiency in ERP software, advanced Excel capabilities, and knowledge of lean inventory principles to drive efficiency and reduce waste.

Inventory Management vs Demand Forecasting

Inventory Planner specializes in optimizing stock levels by managing reorder points, safety stock, and lead times to minimize holding costs and avoid stockouts. Demand Planner focuses on forecasting customer demand using historical sales data, market trends, and seasonality to create accurate demand projections. Effective inventory management balances inventory planner inputs with demand planner forecasts to enhance supply chain efficiency and reduce excess inventory.

Impact on Supply Chain Efficiency

Inventory planners optimize stock levels by analyzing current inventory data and sales trends, reducing carrying costs and minimizing stockouts. Demand planners forecast future product demand using historical sales and market analysis, enabling proactive production scheduling and procurement. Together, they enhance supply chain efficiency by balancing inventory availability with accurate demand predictions, preventing excess stock and missed sales opportunities.

Collaboration with Internal Stakeholders

Inventory planners collaborate closely with sales, procurement, and warehouse teams to optimize stock levels and prevent overstock or stockouts. Demand planners engage with marketing, finance, and customer service departments to forecast accurate demand patterns based on market trends and historical data. Effective collaboration between inventory and demand planners with internal stakeholders ensures synchronized supply chain operations and improved service levels.

Technology and Analytical Tools Utilized

Inventory planners leverage advanced inventory management software and real-time data analytics to optimize stock levels, automate reorder processes, and minimize carrying costs. Demand planners employ predictive analytics, machine learning algorithms, and statistical forecasting tools to accurately anticipate customer demand and adjust supply chain strategies accordingly. Both roles increasingly integrate AI-driven platforms and cloud-based solutions to enhance data accuracy and decision-making efficiency in trade operations.

Performance Metrics and KPIs

Inventory Planner and Demand Planner performance metrics differ significantly, with Inventory Planners focusing on KPIs such as inventory turnover ratio, stockout rate, and carrying cost percentage to optimize stock levels and minimize holding costs. Demand Planners prioritize forecast accuracy, mean absolute percentage error (MAPE), and service level to ensure alignment between demand predictions and actual sales. Both roles use these KPIs to enhance supply chain efficiency but emphasize different aspects of inventory and demand management for operational success.

Career Growth Opportunities

Inventory planners develop expertise in stock management, supplier coordination, and warehouse optimization, leading to roles like supply chain manager or operations director. Demand planners specialize in forecasting, market analysis, and sales trend interpretation, opening paths to strategic planning or business analytics positions. Both careers offer growth through skill enhancement in data-driven decision making and cross-functional collaboration within trade and distribution sectors.

Choosing the Right Planner Role for Your Career

Choosing between an Inventory Planner and a Demand Planner depends on your strengths in trade analytics and forecasting. Inventory Planners specialize in managing stock levels to optimize supply chain efficiency and reduce carrying costs, while Demand Planners focus on predicting customer demand to drive sales and production strategies. Understanding your skill set in data analysis, market trends, and supply chain coordination will help determine the best career path for long-term growth in trade planning roles.

Inventory Planner vs Demand Planner Infographic

jobdiv.com

jobdiv.com