Centralized maintenance consolidates all maintenance activities under a single department, enabling standardized procedures and streamlined resource allocation. Decentralized maintenance distributes responsibilities across multiple departments or locations, allowing faster response times and tailored solutions for specific equipment. Choosing between centralized and decentralized maintenance depends on factors such as organizational size, complexity, and the need for flexibility versus control.

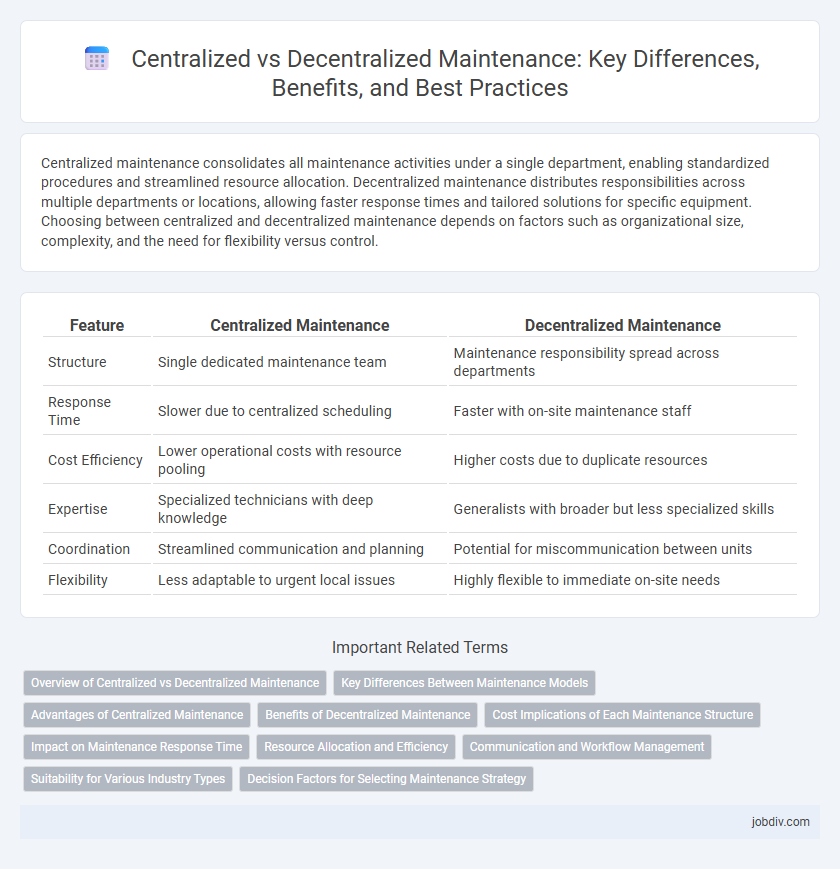

Table of Comparison

| Feature | Centralized Maintenance | Decentralized Maintenance |

|---|---|---|

| Structure | Single dedicated maintenance team | Maintenance responsibility spread across departments |

| Response Time | Slower due to centralized scheduling | Faster with on-site maintenance staff |

| Cost Efficiency | Lower operational costs with resource pooling | Higher costs due to duplicate resources |

| Expertise | Specialized technicians with deep knowledge | Generalists with broader but less specialized skills |

| Coordination | Streamlined communication and planning | Potential for miscommunication between units |

| Flexibility | Less adaptable to urgent local issues | Highly flexible to immediate on-site needs |

Overview of Centralized vs Decentralized Maintenance

Centralized maintenance consolidates all maintenance activities, resources, and decision-making within a single department or location, improving coordination and standardization. Decentralized maintenance distributes responsibilities across multiple departments or sites, enhancing responsiveness and site-specific problem-solving. Comparing both approaches highlights trade-offs between efficiency, control, and adaptability in maintenance management.

Key Differences Between Maintenance Models

Centralized maintenance consolidates all repair and upkeep activities within a single facility, allowing for standardized procedures, centralized inventory control, and streamlined communication, which often results in cost savings and improved expertise. Decentralized maintenance distributes maintenance tasks across multiple locations or departments, enabling faster response times and tailored solutions that align with specific operational needs but may lead to inconsistent practices and higher inventory costs. Key differences include centralized maintenance's focus on uniformity and resource optimization versus decentralized maintenance's emphasis on flexibility and immediate access to skilled personnel.

Advantages of Centralized Maintenance

Centralized maintenance streamlines resource allocation by consolidating skilled technicians, tools, and spare parts in a single location, enhancing efficiency and reducing downtime. It facilitates standardized procedures and consistent quality control, improving equipment reliability and reducing operational costs across multiple sites. Centralized data management enables more accurate monitoring and predictive maintenance, leading to proactive issue resolution and extended asset lifespan.

Benefits of Decentralized Maintenance

Decentralized maintenance enhances responsiveness by empowering local teams to address equipment issues immediately, reducing downtime significantly. It fosters specialized expertise within individual units, improving the accuracy of diagnostics and repairs. This approach also promotes flexibility and adaptability, enabling quicker adjustments to operational changes and preventing bottlenecks associated with centralized control.

Cost Implications of Each Maintenance Structure

Centralized maintenance often reduces overall costs through bulk purchasing of parts and standardized training programs, resulting in lower inventory and labor expenses. Decentralized maintenance may increase operational costs due to duplicated resources, varied equipment handling, and inconsistent maintenance practices across multiple locations. The choice between the two structures significantly impacts maintenance budgeting, with centralized systems favoring economies of scale while decentralized systems may incur higher direct and indirect costs.

Impact on Maintenance Response Time

Centralized maintenance can lead to longer response times due to the physical distance between the maintenance team and equipment sites, causing delays in issue resolution. In contrast, decentralized maintenance places skilled personnel closer to operational areas, significantly reducing response times and enabling faster troubleshooting and repairs. Faster response times in decentralized systems often result in minimized equipment downtime and improved overall operational efficiency.

Resource Allocation and Efficiency

Centralized maintenance optimizes resource allocation by consolidating skilled personnel and specialized tools in a single location, enhancing efficiency through streamlined workflows and reduced redundancy. Decentralized maintenance allocates resources across multiple sites, enabling quicker response times and localized expertise but may lead to higher operational costs and potential resource duplication. Efficient maintenance strategies balance centralized control with decentralized flexibility to maximize asset uptime and minimize overall expenditure.

Communication and Workflow Management

Centralized maintenance enhances communication by consolidating information flow through a unified system, reducing miscommunication and streamlining workflow management across departments. Decentralized maintenance allows quicker decision-making and local responsiveness, but may suffer from inconsistent communication and fragmented workflows. Effective maintenance operations depend on balancing centralized coordination with decentralized execution to optimize communication clarity and workflow efficiency.

Suitability for Various Industry Types

Centralized maintenance systems are highly suitable for large-scale industries with standardized equipment, such as manufacturing plants or automotive factories, where uniformity and resource pooling enhance efficiency. Decentralized maintenance excels in industries with diverse or geographically dispersed assets, including oil and gas fields or retail chains, allowing rapid local response and tailored interventions. Choosing between centralized and decentralized maintenance depends on factors like industry complexity, asset distribution, and required flexibility for operational continuity.

Decision Factors for Selecting Maintenance Strategy

Decision factors for selecting between centralized and decentralized maintenance strategies include the scale of operations, equipment complexity, and geographic distribution of assets. Centralized maintenance is optimal for large organizations with uniform equipment requiring specialized expertise and streamlined coordination. Decentralized maintenance suits businesses with diverse, dispersed facilities needing rapid response and localized decision-making.

Centralized Maintenance vs Decentralized Maintenance Infographic

jobdiv.com

jobdiv.com