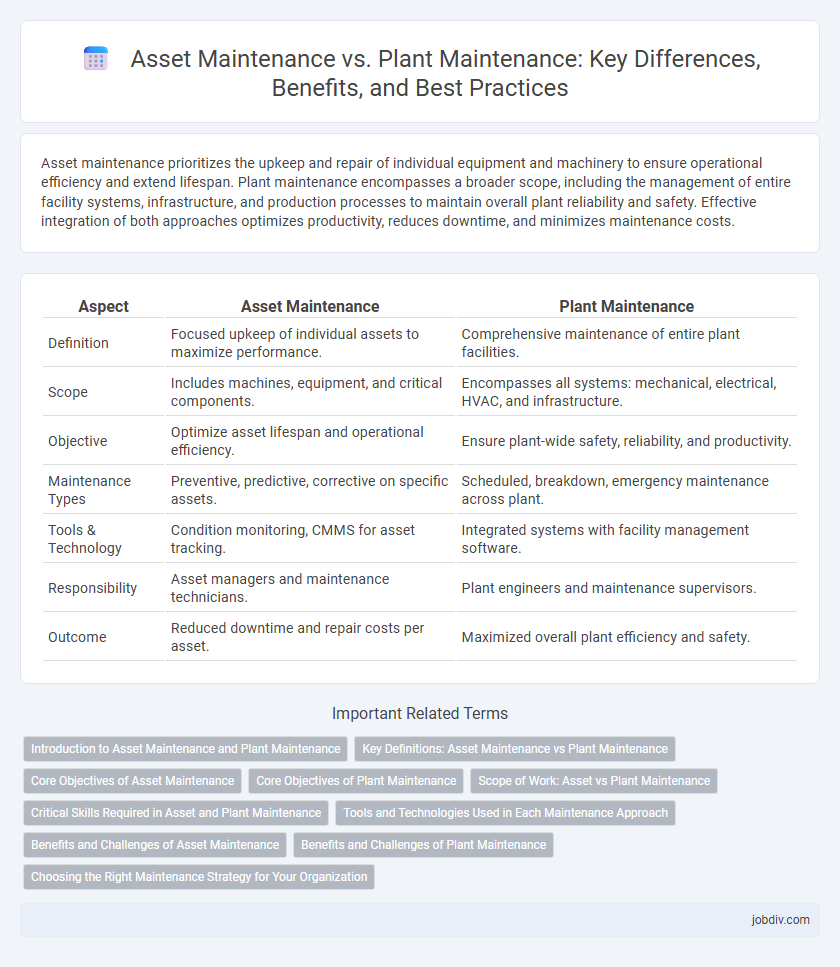

Asset maintenance prioritizes the upkeep and repair of individual equipment and machinery to ensure operational efficiency and extend lifespan. Plant maintenance encompasses a broader scope, including the management of entire facility systems, infrastructure, and production processes to maintain overall plant reliability and safety. Effective integration of both approaches optimizes productivity, reduces downtime, and minimizes maintenance costs.

Table of Comparison

| Aspect | Asset Maintenance | Plant Maintenance |

|---|---|---|

| Definition | Focused upkeep of individual assets to maximize performance. | Comprehensive maintenance of entire plant facilities. |

| Scope | Includes machines, equipment, and critical components. | Encompasses all systems: mechanical, electrical, HVAC, and infrastructure. |

| Objective | Optimize asset lifespan and operational efficiency. | Ensure plant-wide safety, reliability, and productivity. |

| Maintenance Types | Preventive, predictive, corrective on specific assets. | Scheduled, breakdown, emergency maintenance across plant. |

| Tools & Technology | Condition monitoring, CMMS for asset tracking. | Integrated systems with facility management software. |

| Responsibility | Asset managers and maintenance technicians. | Plant engineers and maintenance supervisors. |

| Outcome | Reduced downtime and repair costs per asset. | Maximized overall plant efficiency and safety. |

Introduction to Asset Maintenance and Plant Maintenance

Asset Maintenance involves managing and preserving individual assets, such as machinery or equipment, to ensure optimal functionality and extend their lifespan. Plant Maintenance encompasses the comprehensive upkeep, repair, and operational reliability of an entire manufacturing or processing facility. Both practices aim to reduce downtime and increase productivity through systematic inspection, preventive measures, and timely repairs.

Key Definitions: Asset Maintenance vs Plant Maintenance

Asset maintenance involves the systematic upkeep and repair of individual assets such as machinery, equipment, or vehicles to ensure their optimal performance and longevity. Plant maintenance refers to the comprehensive management of an entire production facility, including physical infrastructure, systems, and assets, aimed at minimizing downtime and maximizing operational efficiency. Understanding the distinction between asset maintenance and plant maintenance is crucial for developing targeted strategies that address specific components or the broader operational environment.

Core Objectives of Asset Maintenance

Asset maintenance primarily focuses on preserving the operational efficiency and longevity of individual assets through regular inspections, preventive repairs, and condition monitoring. Core objectives include minimizing downtime, optimizing asset performance, and reducing lifecycle costs by addressing wear and tear proactively. This contrasts with plant maintenance, which encompasses broader system-level upkeep involving multiple assets and infrastructure coordination.

Core Objectives of Plant Maintenance

Plant maintenance prioritizes ensuring continuous and efficient operation of production equipment by minimizing downtime and preventing unexpected failures through systematic inspections and repairs. Asset maintenance focuses more broadly on preserving the value, functionality, and lifespan of all physical assets, including machinery, buildings, and infrastructure. Core objectives of plant maintenance include maximizing equipment availability, optimizing maintenance costs, enhancing safety standards, and supporting overall production goals.

Scope of Work: Asset vs Plant Maintenance

Asset maintenance focuses on individual equipment or machinery, ensuring each asset operates efficiently and minimizing downtime through targeted inspections, repairs, and performance monitoring. Plant maintenance involves a broader scope, encompassing the entire production facility, including infrastructure, utilities, and support systems, to maintain overall operational continuity and safety. The scope of work in asset maintenance is narrower and more detailed, while plant maintenance requires integrated management of multiple assets and systems.

Critical Skills Required in Asset and Plant Maintenance

Effective asset maintenance demands critical skills such as predictive analytics, equipment diagnostics, and asset lifecycle management to ensure optimal performance and longevity. Plant maintenance requires expertise in mechanical systems, process optimization, and safety compliance to maintain continuous production and minimize downtime. Mastery of these skills directly impacts operational efficiency and cost savings in industrial environments.

Tools and Technologies Used in Each Maintenance Approach

Asset maintenance utilizes condition monitoring tools such as vibration analyzers, thermal imaging cameras, and IoT sensors to track equipment health and predict failures. Plant maintenance employs integrated software platforms like computerized maintenance management systems (CMMS) and enterprise resource planning (ERP) to coordinate maintenance activities and optimize resource allocation. Advanced technologies including augmented reality (AR) and drones support both approaches by enhancing inspection accuracy and reducing downtime.

Benefits and Challenges of Asset Maintenance

Asset maintenance focuses on preserving individual equipment functionality, improving reliability, and reducing unexpected downtime, which enhances overall operational efficiency. Challenges include the need for detailed tracking of asset conditions and specialized knowledge to address diverse equipment requirements. Benefits of asset maintenance encompass increased lifespan of machinery, optimized repair costs, and targeted interventions that prevent major failures.

Benefits and Challenges of Plant Maintenance

Plant maintenance enhances operational efficiency by minimizing unplanned downtime and extending the lifespan of critical equipment, leading to reduced repair costs and improved safety compliance. It faces challenges such as high initial investment, the need for skilled personnel, and maintaining comprehensive maintenance schedules across complex systems. Effective plant maintenance relies on predictive analytics and real-time monitoring to balance cost control with maximizing asset availability.

Choosing the Right Maintenance Strategy for Your Organization

Choosing the right maintenance strategy requires understanding the difference between asset maintenance, which focuses on individual equipment health, and plant maintenance, which encompasses the entire facility's operational efficiency. Asset maintenance emphasizes preventive and predictive tasks for critical machinery, ensuring minimal downtime and extended equipment lifespan. Plant maintenance integrates workflows across all assets, optimizing resources and aligning maintenance goals with overall production targets to maximize organizational performance.

Asset Maintenance vs Plant Maintenance Infographic

jobdiv.com

jobdiv.com