Plant maintenance involves the upkeep and repair of industrial machinery and equipment to ensure efficient production processes, while building maintenance focuses on preserving the structural integrity and aesthetics of physical infrastructures such as walls, roofs, and electrical systems. Both types of maintenance require scheduled inspections, preventive measures, and timely repairs but address distinctly different operational priorities. Effective plant maintenance minimizes downtime and enhances safety in manufacturing environments, whereas building maintenance ensures a safe, functional, and comfortable environment for occupants.

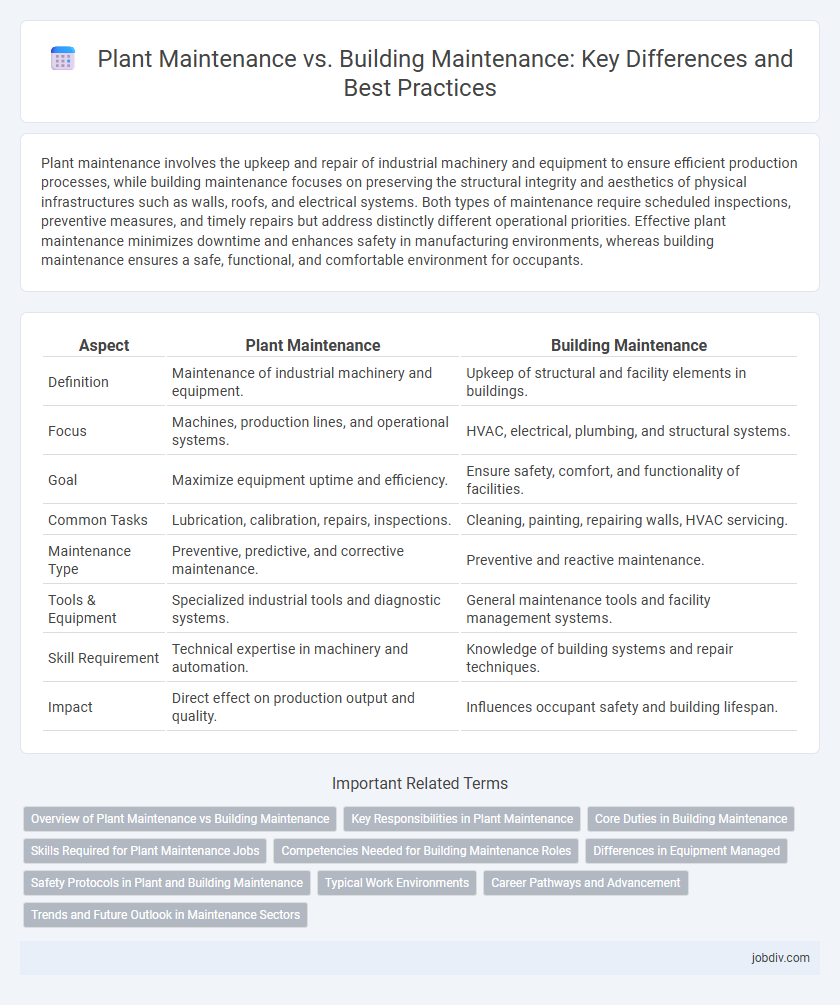

Table of Comparison

| Aspect | Plant Maintenance | Building Maintenance |

|---|---|---|

| Definition | Maintenance of industrial machinery and equipment. | Upkeep of structural and facility elements in buildings. |

| Focus | Machines, production lines, and operational systems. | HVAC, electrical, plumbing, and structural systems. |

| Goal | Maximize equipment uptime and efficiency. | Ensure safety, comfort, and functionality of facilities. |

| Common Tasks | Lubrication, calibration, repairs, inspections. | Cleaning, painting, repairing walls, HVAC servicing. |

| Maintenance Type | Preventive, predictive, and corrective maintenance. | Preventive and reactive maintenance. |

| Tools & Equipment | Specialized industrial tools and diagnostic systems. | General maintenance tools and facility management systems. |

| Skill Requirement | Technical expertise in machinery and automation. | Knowledge of building systems and repair techniques. |

| Impact | Direct effect on production output and quality. | Influences occupant safety and building lifespan. |

Overview of Plant Maintenance vs Building Maintenance

Plant maintenance involves the upkeep and repair of machinery and equipment critical to manufacturing processes, ensuring operational efficiency and minimizing downtime. Building maintenance focuses on the preservation of structural elements, HVAC systems, electrical installations, and safety compliance to provide a safe and functional environment. Both types of maintenance require scheduled inspections, preventive measures, and prompt repairs but differ fundamentally in their targeted assets and technical requirements.

Key Responsibilities in Plant Maintenance

Plant maintenance involves routine inspection, repair, and preventive measures to ensure machinery and equipment operate efficiently and minimize downtime. Key responsibilities include scheduling regular equipment servicing, troubleshooting mechanical failures, and maintaining compliance with safety and environmental regulations. This contrasts with building maintenance, which centers on the upkeep of structural components, HVAC systems, and facility cleanliness.

Core Duties in Building Maintenance

Building maintenance primarily involves the upkeep of structural elements such as walls, roofs, windows, and doors to ensure safety and functionality. It includes routine inspections, repairs of electrical and plumbing systems, and HVAC maintenance to optimize building performance. Preventive measures like painting, cleaning, and pest control are essential for preserving building integrity and extending its lifespan.

Skills Required for Plant Maintenance Jobs

Plant maintenance jobs demand specialized skills in mechanical systems, electrical troubleshooting, and automation technology, ensuring efficient operation of industrial equipment. Proficiency in predictive and preventive maintenance techniques is essential to minimize downtime and extend machinery lifespan. Knowledge of safety regulations, instrumentation, and control systems further distinguishes plant maintenance professionals from those focused on general building maintenance.

Competencies Needed for Building Maintenance Roles

Building maintenance roles require competencies in electrical systems, HVAC operation, plumbing, and safety regulations to ensure functional and compliant facilities. Proficiency in preventive maintenance techniques and troubleshooting skills is essential for minimizing downtime and extending equipment life. Knowledge of building codes, environmental standards, and communication abilities supports effective coordination with contractors and facility managers.

Differences in Equipment Managed

Plant maintenance primarily manages industrial equipment such as machinery, conveyors, and production lines critical for manufacturing operations. Building maintenance focuses on infrastructure elements like HVAC systems, electrical wiring, plumbing, and structural repairs. The key difference lies in the complexity and specificity of equipment, with plant maintenance requiring specialized technical expertise for machinery upkeep, while building maintenance centers on facility systems and structural integrity.

Safety Protocols in Plant and Building Maintenance

Safety protocols in plant maintenance emphasize strict adherence to machinery lockout/tagout procedures, personal protective equipment (PPE) usage, and regular hazard assessments to prevent industrial accidents. Building maintenance safety focuses on ensuring structural integrity, safe handling of electrical and plumbing systems, and fire safety measures like sprinkler inspections and clear evacuation routes. Both domains require rigorous training and compliance with OSHA standards to minimize workplace risks and maintain a secure environment.

Typical Work Environments

Plant maintenance typically occurs in industrial settings such as manufacturing facilities, power plants, and refineries where heavy machinery and complex systems require regular inspection and repairs. Building maintenance, on the other hand, is performed in commercial, residential, or institutional structures focusing on HVAC systems, plumbing, electrical systems, and general upkeep. Both require specialized skills, but plant maintenance emphasizes machinery optimization, while building maintenance prioritizes structural integrity and occupant safety.

Career Pathways and Advancement

Plant maintenance careers typically emphasize mechanical, electrical, and process-oriented skills, offering advancement opportunities in industrial automation, reliability engineering, and production supervision. Building maintenance pathways focus on facility management, HVAC systems, and safety compliance, leading to roles such as facility manager, building systems engineer, or property manager. Both fields value certifications and hands-on experience, but plant maintenance often demands specialized technical expertise, while building maintenance prioritizes operational efficiency and regulatory knowledge.

Trends and Future Outlook in Maintenance Sectors

Plant maintenance emphasizes predictive analytics and IoT integration to minimize downtime and optimize operational efficiency, while building maintenance increasingly adopts smart building technologies for energy management and occupant comfort. The future outlook highlights a digital transformation across both sectors, leveraging AI-driven maintenance scheduling and remote monitoring systems to enhance asset lifespan and reduce costs. Sustainability and automation emerge as critical trends shaping maintenance strategies, driving innovation in condition-based interventions and resource-efficient practices.

Plant Maintenance vs Building Maintenance Infographic

jobdiv.com

jobdiv.com