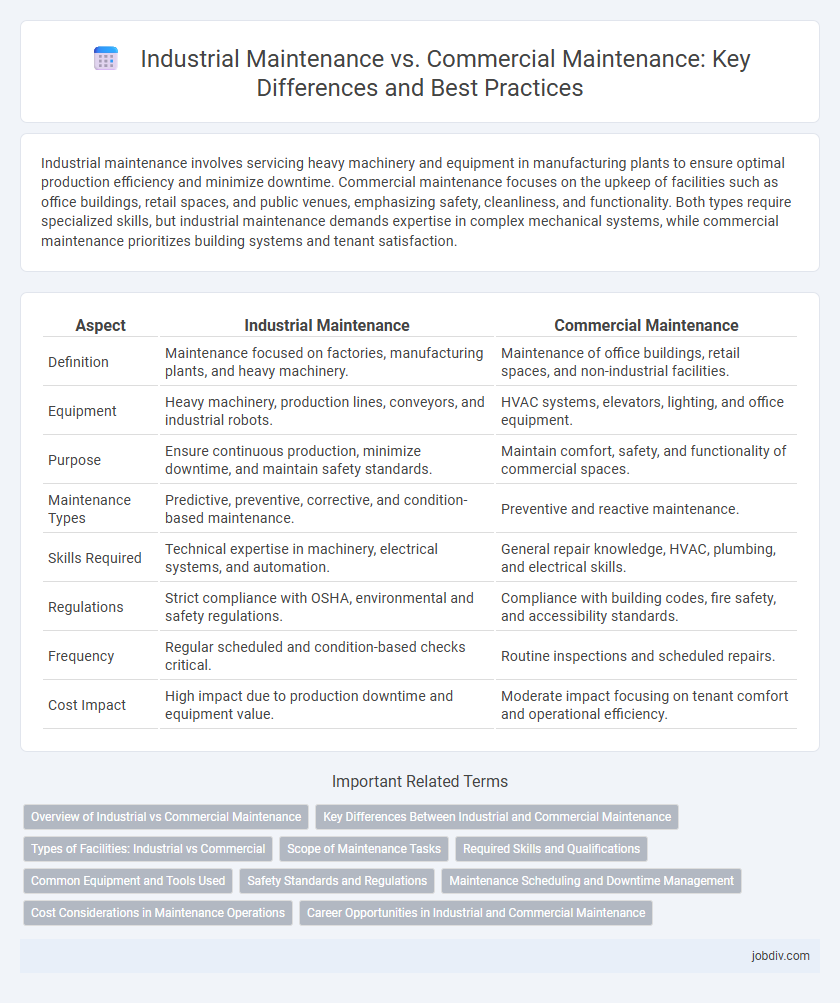

Industrial maintenance involves servicing heavy machinery and equipment in manufacturing plants to ensure optimal production efficiency and minimize downtime. Commercial maintenance focuses on the upkeep of facilities such as office buildings, retail spaces, and public venues, emphasizing safety, cleanliness, and functionality. Both types require specialized skills, but industrial maintenance demands expertise in complex mechanical systems, while commercial maintenance prioritizes building systems and tenant satisfaction.

Table of Comparison

| Aspect | Industrial Maintenance | Commercial Maintenance |

|---|---|---|

| Definition | Maintenance focused on factories, manufacturing plants, and heavy machinery. | Maintenance of office buildings, retail spaces, and non-industrial facilities. |

| Equipment | Heavy machinery, production lines, conveyors, and industrial robots. | HVAC systems, elevators, lighting, and office equipment. |

| Purpose | Ensure continuous production, minimize downtime, and maintain safety standards. | Maintain comfort, safety, and functionality of commercial spaces. |

| Maintenance Types | Predictive, preventive, corrective, and condition-based maintenance. | Preventive and reactive maintenance. |

| Skills Required | Technical expertise in machinery, electrical systems, and automation. | General repair knowledge, HVAC, plumbing, and electrical skills. |

| Regulations | Strict compliance with OSHA, environmental and safety regulations. | Compliance with building codes, fire safety, and accessibility standards. |

| Frequency | Regular scheduled and condition-based checks critical. | Routine inspections and scheduled repairs. |

| Cost Impact | High impact due to production downtime and equipment value. | Moderate impact focusing on tenant comfort and operational efficiency. |

Overview of Industrial vs Commercial Maintenance

Industrial maintenance primarily involves the upkeep of heavy machinery, manufacturing equipment, and production lines, emphasizing preventive and predictive techniques to minimize downtime and ensure safety compliance. Commercial maintenance focuses on maintaining building systems such as HVAC, plumbing, electrical, and cleaning services in offices, retail spaces, and public facilities, prioritizing occupant comfort and operational efficiency. Both types require specialized skills and tailored strategies to address the unique demands of their respective environments.

Key Differences Between Industrial and Commercial Maintenance

Industrial maintenance primarily involves servicing heavy machinery, production lines, and large-scale equipment to ensure continuous manufacturing operations, often requiring specialized technical skills and compliance with stringent safety standards. Commercial maintenance focuses on maintaining building systems such as HVAC, electrical, plumbing, and general repairs in retail, office, or institutional settings, emphasizing occupant comfort and regulatory code adherence. The key differences include the complexity of equipment, scope of work, and industry-specific regulations governing maintenance practices.

Types of Facilities: Industrial vs Commercial

Industrial maintenance involves servicing facilities such as manufacturing plants, warehouses, and production lines, where heavy machinery, specialized equipment, and complex mechanical systems require routine inspection and repair. Commercial maintenance targets buildings like office complexes, retail stores, and hospitality venues, focusing on HVAC systems, electrical fixtures, plumbing, and structural upkeep to ensure safe and efficient operation. The distinct facility types dictate the specific maintenance protocols, safety standards, and technical expertise necessary for effective operational continuity.

Scope of Maintenance Tasks

Industrial maintenance primarily involves the upkeep of heavy machinery, production equipment, and complex systems within manufacturing plants, requiring specialized technical skills and adherence to strict safety standards. Commercial maintenance focuses on the maintenance of office buildings, retail spaces, and public facilities, addressing tasks such as HVAC servicing, electrical repairs, and janitorial services to ensure operational efficiency and comfort. The scope of industrial maintenance is typically broader and more technical, emphasizing preventive and predictive maintenance, while commercial maintenance concentrates on routine inspections and prompt repairs to support daily business operations.

Required Skills and Qualifications

Industrial maintenance demands expertise in heavy machinery operation, electrical systems, and advanced troubleshooting, often requiring certifications like OSHA and knowledge of PLC programming. Commercial maintenance prioritizes skills in HVAC systems, plumbing, and general building repairs, with qualifications such as EPA certification and familiarity with local code compliance. Both fields require strong problem-solving abilities, but industrial maintenance leans more towards technical and safety-specific training.

Common Equipment and Tools Used

Industrial maintenance typically involves heavy machinery such as conveyor belts, hydraulic presses, and large motors, requiring specialized tools like torque wrenches, vibration analyzers, and thermal imaging cameras. Commercial maintenance focuses on equipment related to building systems, including HVAC units, elevators, and electrical panels, using multimeters, refrigerant gauges, and pipe wrenches for repairs. Both sectors rely on preventive maintenance tools like lubricants, inspection mirrors, and portable diagnostic devices to ensure operational efficiency and reduce downtime.

Safety Standards and Regulations

Industrial maintenance strictly adheres to rigorous safety standards such as OSHA and NFPA regulations to mitigate hazards associated with heavy machinery and high-risk environments. Commercial maintenance follows safety protocols tailored to public spaces, emphasizing compliance with ADA standards and fire safety codes to ensure occupant protection. Both sectors require regular inspections and employee training to maintain compliance and promote a safe working environment.

Maintenance Scheduling and Downtime Management

Industrial maintenance scheduling involves complex coordination across heavy machinery and production lines to minimize downtime and optimize operational efficiency. Commercial maintenance scheduling prioritizes routine inspections and rapid response to reduce disruptions in service environments such as retail or office spaces. Effective downtime management in industrial settings focuses on predictive maintenance using IoT sensors, while commercial maintenance emphasizes preventive strategies to ensure tenant satisfaction and business continuity.

Cost Considerations in Maintenance Operations

Industrial maintenance typically involves higher costs due to the complexity of machinery, specialized labor, and stringent safety regulations required to ensure continuous production. Commercial maintenance tends to have lower expenses, focusing on building upkeep, HVAC systems, and routine repairs across office or retail environments. Budget allocation for industrial maintenance must account for predictive analytics and downtime minimization, whereas commercial maintenance prioritizes cost-effective scheduling and preventive measures.

Career Opportunities in Industrial and Commercial Maintenance

Industrial maintenance careers offer opportunities in manufacturing plants, power generation, and heavy machinery, with roles such as maintenance technicians, engineers, and equipment specialists requiring advanced technical skills. Commercial maintenance focuses on facilities management, HVAC systems, and building automation in office complexes, retail spaces, and healthcare facilities, emphasizing preventive maintenance and customer service. Both sectors demand strong troubleshooting abilities, but industrial maintenance often provides higher salaries and more specialized skill development due to the complexity of industrial equipment.

Industrial Maintenance vs Commercial Maintenance Infographic

jobdiv.com

jobdiv.com