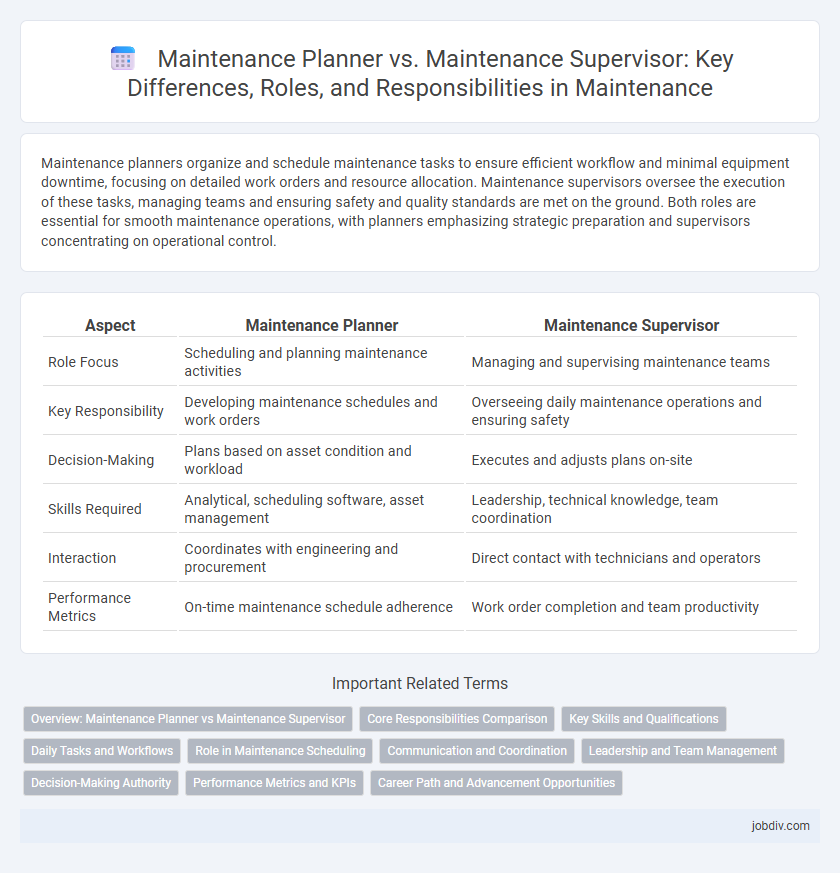

Maintenance planners organize and schedule maintenance tasks to ensure efficient workflow and minimal equipment downtime, focusing on detailed work orders and resource allocation. Maintenance supervisors oversee the execution of these tasks, managing teams and ensuring safety and quality standards are met on the ground. Both roles are essential for smooth maintenance operations, with planners emphasizing strategic preparation and supervisors concentrating on operational control.

Table of Comparison

| Aspect | Maintenance Planner | Maintenance Supervisor |

|---|---|---|

| Role Focus | Scheduling and planning maintenance activities | Managing and supervising maintenance teams |

| Key Responsibility | Developing maintenance schedules and work orders | Overseeing daily maintenance operations and ensuring safety |

| Decision-Making | Plans based on asset condition and workload | Executes and adjusts plans on-site |

| Skills Required | Analytical, scheduling software, asset management | Leadership, technical knowledge, team coordination |

| Interaction | Coordinates with engineering and procurement | Direct contact with technicians and operators |

| Performance Metrics | On-time maintenance schedule adherence | Work order completion and team productivity |

Overview: Maintenance Planner vs Maintenance Supervisor

A Maintenance Planner is responsible for scheduling, coordinating, and organizing maintenance activities to maximize equipment uptime and ensure efficient resource allocation. In contrast, a Maintenance Supervisor oversees the execution of maintenance tasks, manages maintenance teams, monitors performance, and enforces safety standards on-site. Both roles are critical to effective maintenance operations, with planners focusing on strategic preparation and supervisors emphasizing operational management.

Core Responsibilities Comparison

Maintenance planners develop detailed schedules, coordinate resources, and ensure preventive maintenance tasks align with operational goals, optimizing equipment uptime. Maintenance supervisors oversee daily maintenance activities, manage technician teams, and ensure compliance with safety standards and quality controls on-site. Both roles collaborate to enhance maintenance efficiency but focus respectively on strategic planning and hands-on execution.

Key Skills and Qualifications

Maintenance planners excel in scheduling, resource allocation, and data analysis, requiring strong organizational skills and proficiency in maintenance management software. Maintenance supervisors demonstrate expertise in team leadership, hands-on technical knowledge, and compliance with safety regulations, emphasizing effective communication and problem-solving abilities. Both roles demand a solid understanding of equipment maintenance, but planners focus on strategic coordination while supervisors prioritize operational execution.

Daily Tasks and Workflows

A Maintenance Planner develops and schedules preventive and corrective maintenance tasks, coordinates resources, and ensures availability of materials and equipment. A Maintenance Supervisor oversees daily maintenance operations, manages technicians, monitors task progress, and enforces safety and quality standards. Both roles collaborate to optimize workflows, reduce downtime, and enhance equipment reliability.

Role in Maintenance Scheduling

A Maintenance Planner develops detailed schedules that allocate resources, materials, and labor for preventive and corrective maintenance activities, ensuring optimal equipment uptime and efficient workflow. A Maintenance Supervisor oversees the execution of these schedules on-site, coordinating technicians, verifying task completion, and addressing real-time issues to maintain operational continuity. The planner focuses on strategic scheduling and resource allocation, while the supervisor emphasizes day-to-day task management and supervision in maintenance operations.

Communication and Coordination

A Maintenance Planner organizes and schedules maintenance activities, ensuring efficient resource allocation and timely completion, while a Maintenance Supervisor oversees on-site operations, directing teams and resolving issues in real-time. Effective communication for a Maintenance Planner involves detailed documentation and coordination with procurement and production departments to minimize downtime. Maintenance Supervisors excel in direct interpersonal communication, providing immediate feedback to technicians and facilitating quick problem-solving during maintenance execution.

Leadership and Team Management

Maintenance Planners prioritize optimizing work schedules and resource allocation to ensure efficient task completion, driving productivity through detailed planning and coordination. Maintenance Supervisors focus on leadership by directly managing teams, providing guidance, motivation, and resolving on-site issues to maintain operational continuity. Effective maintenance operations rely on the planner's foresight combined with the supervisor's hands-on team management to enhance overall equipment reliability.

Decision-Making Authority

Maintenance Planners primarily focus on creating detailed maintenance schedules and resource allocation plans based on equipment data and operational priorities. Maintenance Supervisors hold greater decision-making authority, overseeing maintenance teams, prioritizing tasks in real time, and approving adjustments to schedules to address urgent repair needs. The supervisor's role involves balancing strategic plans with immediate operational demands, ensuring efficient maintenance execution while minimizing downtime.

Performance Metrics and KPIs

Maintenance Planners and Maintenance Supervisors both focus on performance metrics but with different KPIs tailored to their roles; planners prioritize scheduling accuracy, work order completion rate, and backlog reduction, ensuring optimal resource allocation and minimizing downtime. Supervisors emphasize team productivity, safety compliance, and first-time fix rate, closely monitoring technician efficiency and incident reports to maintain operational excellence. Tracking these role-specific KPIs enhances overall maintenance performance and supports strategic decision-making.

Career Path and Advancement Opportunities

Maintenance Planners focus on scheduling and coordinating maintenance activities, laying a strong foundation for advancing into supervisory roles by developing organizational and analytical skills critical for leadership. Maintenance Supervisors manage teams and oversee daily maintenance operations, providing direct experience in personnel management and decision-making that opens pathways to higher management positions such as Maintenance Manager or Operations Director. Career advancement typically progresses from Planner to Supervisor, leveraging technical expertise and leadership abilities to transition into strategic roles within maintenance and facilities management.

Maintenance Planner vs Maintenance Supervisor Infographic

jobdiv.com

jobdiv.com