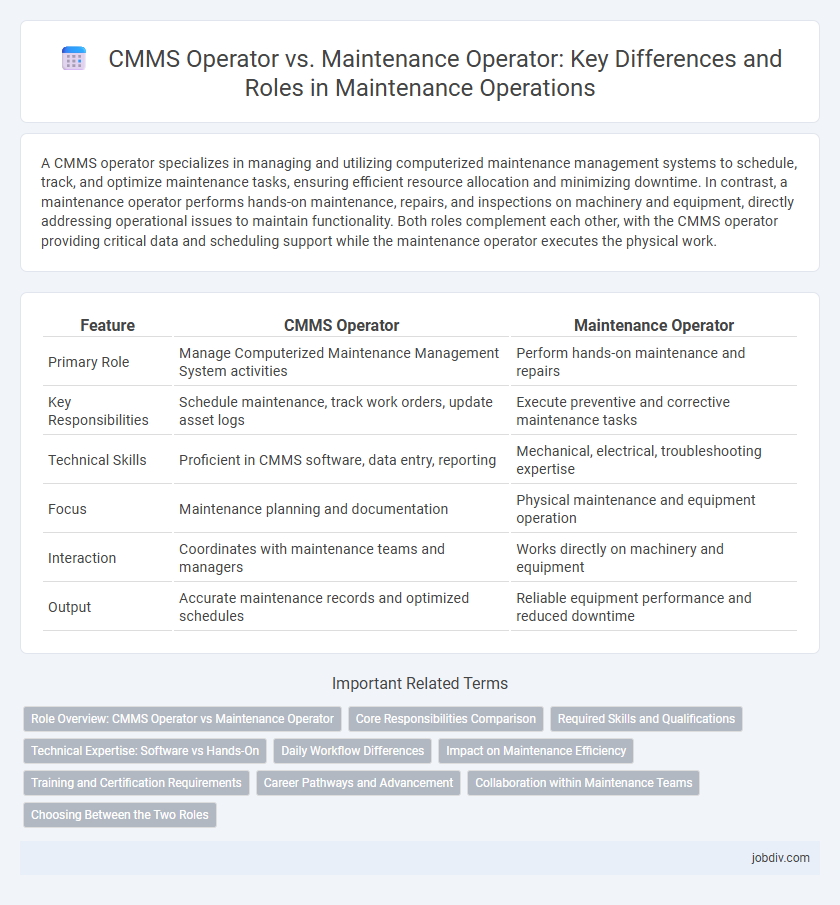

A CMMS operator specializes in managing and utilizing computerized maintenance management systems to schedule, track, and optimize maintenance tasks, ensuring efficient resource allocation and minimizing downtime. In contrast, a maintenance operator performs hands-on maintenance, repairs, and inspections on machinery and equipment, directly addressing operational issues to maintain functionality. Both roles complement each other, with the CMMS operator providing critical data and scheduling support while the maintenance operator executes the physical work.

Table of Comparison

| Feature | CMMS Operator | Maintenance Operator |

|---|---|---|

| Primary Role | Manage Computerized Maintenance Management System activities | Perform hands-on maintenance and repairs |

| Key Responsibilities | Schedule maintenance, track work orders, update asset logs | Execute preventive and corrective maintenance tasks |

| Technical Skills | Proficient in CMMS software, data entry, reporting | Mechanical, electrical, troubleshooting expertise |

| Focus | Maintenance planning and documentation | Physical maintenance and equipment operation |

| Interaction | Coordinates with maintenance teams and managers | Works directly on machinery and equipment |

| Output | Accurate maintenance records and optimized schedules | Reliable equipment performance and reduced downtime |

Role Overview: CMMS Operator vs Maintenance Operator

A CMMS Operator primarily manages computerized maintenance management systems, ensuring accurate data input, work order scheduling, and system updates to optimize maintenance workflows. A Maintenance Operator focuses on hands-on execution of maintenance tasks, equipment inspections, repairs, and preventive maintenance activities on-site. Both roles are critical for effective asset management but differ in their emphasis on digital system management versus physical maintenance operations.

Core Responsibilities Comparison

CMMS Operators primarily manage computerized maintenance management system data, ensuring accurate work order processing, inventory tracking, and reporting for efficient maintenance workflow. Maintenance Operators focus on hands-on equipment operation, performing routine inspections, preventive maintenance, and basic repairs to maintain machinery functionality. While CMMS Operators emphasize data accuracy and system coordination, Maintenance Operators prioritize physical equipment upkeep and operational reliability.

Required Skills and Qualifications

A CMMS Operator must possess advanced computer literacy, proficiency in software navigation, and data entry accuracy to manage maintenance schedules and generate reports efficiently. In contrast, a Maintenance Operator requires strong mechanical aptitude, troubleshooting expertise, and hands-on experience with equipment repair and preventive maintenance tasks. Both roles demand solid communication skills and attention to detail, but the CMMS Operator emphasizes technical software competencies, while the Maintenance Operator prioritizes practical maintenance and operational knowledge.

Technical Expertise: Software vs Hands-On

A CMMS Operator possesses specialized technical expertise in software management, utilizing computerized maintenance management systems to schedule, track, and analyze maintenance tasks. In contrast, a Maintenance Operator demonstrates hands-on technical skills, directly performing equipment repairs, inspections, and preventive maintenance in the field. These complementary roles emphasize digital proficiency for CMMS Operators and practical mechanical aptitude for Maintenance Operators within maintenance operations.

Daily Workflow Differences

A CMMS operator primarily focuses on using computerized maintenance management systems to schedule, track, and record maintenance activities, ensuring data accuracy and timely updates for preventive and corrective tasks. In contrast, a maintenance operator engages directly with machinery and equipment to perform hands-on repairs, inspections, and routine maintenance based on the schedules and alerts generated by the CMMS. Daily workflow differences center on digital task management for CMMS operators, while maintenance operators prioritize physical execution and troubleshooting on the shop floor.

Impact on Maintenance Efficiency

A CMMS Operator leverages computerized maintenance management systems to schedule, track, and document maintenance activities, significantly enhancing data accuracy and resource allocation. In contrast, a Maintenance Operator primarily performs hands-on repair and upkeep tasks but may lack the optimized use of digital tools, potentially limiting efficiency gains. Integrating both roles enables streamlined workflows and improved preventive maintenance, leading to reduced downtime and cost savings.

Training and Certification Requirements

CMMS Operators require comprehensive training in computerized maintenance management systems, including software navigation, data entry accuracy, and report generation, often supported by certifications such as Certified Maintenance & Reliability Technician (CMRT). Maintenance Operators focus on hands-on technical skills related to equipment repair and preventive maintenance, typically requiring certifications like OSHA safety training or specific trade qualifications. Companies increasingly emphasize cross-training to ensure Maintenance Operators can effectively utilize CMMS platforms while CMMS Operators understand basic mechanical processes.

Career Pathways and Advancement

CMMS operators specialize in computerized maintenance management systems, optimizing asset tracking and work order management, which positions them for roles in data analysis and system administration within maintenance departments. Maintenance operators possess hands-on technical skills in equipment repair and preventive maintenance, providing a foundation for advancement into supervisory or specialized technician roles. Both career pathways offer opportunities for growth, but CMMS operators often advance toward maintenance planning and reliability engineering due to their expertise in digital tools.

Collaboration within Maintenance Teams

CMMS Operators streamline maintenance workflows by managing computerized maintenance management system data, ensuring accurate work orders and equipment histories, while Maintenance Operators execute hands-on tasks to maintain machinery functionality. Effective collaboration between CMMS Operators and Maintenance Operators maximizes operational efficiency by aligning digital asset management with practical maintenance execution. Integrating real-time feedback from Maintenance Operators into the CMMS enhances predictive maintenance strategies and minimizes downtime across manufacturing and industrial facilities.

Choosing Between the Two Roles

Choosing between a CMMS Operator and a Maintenance Operator depends on the organization's focus on digital asset management versus hands-on technical skills. CMMS Operators specialize in managing computerized maintenance management systems to track work orders, schedule preventive maintenance, and analyze equipment performance data. Maintenance Operators concentrate on executing repair tasks, conducting inspections, and maintaining machinery to ensure operational efficiency and minimize downtime.

CMMS Operator vs Maintenance Operator Infographic

jobdiv.com

jobdiv.com