Predictive maintenance uses real-time data and advanced analytics to anticipate equipment failures before they occur, reducing downtime and maintenance costs. Preventive maintenance follows a scheduled plan based on time or usage intervals, aiming to prevent breakdowns through regular inspections and part replacements. Both strategies enhance asset reliability, but predictive maintenance offers a more efficient approach by targeting issues precisely when needed.

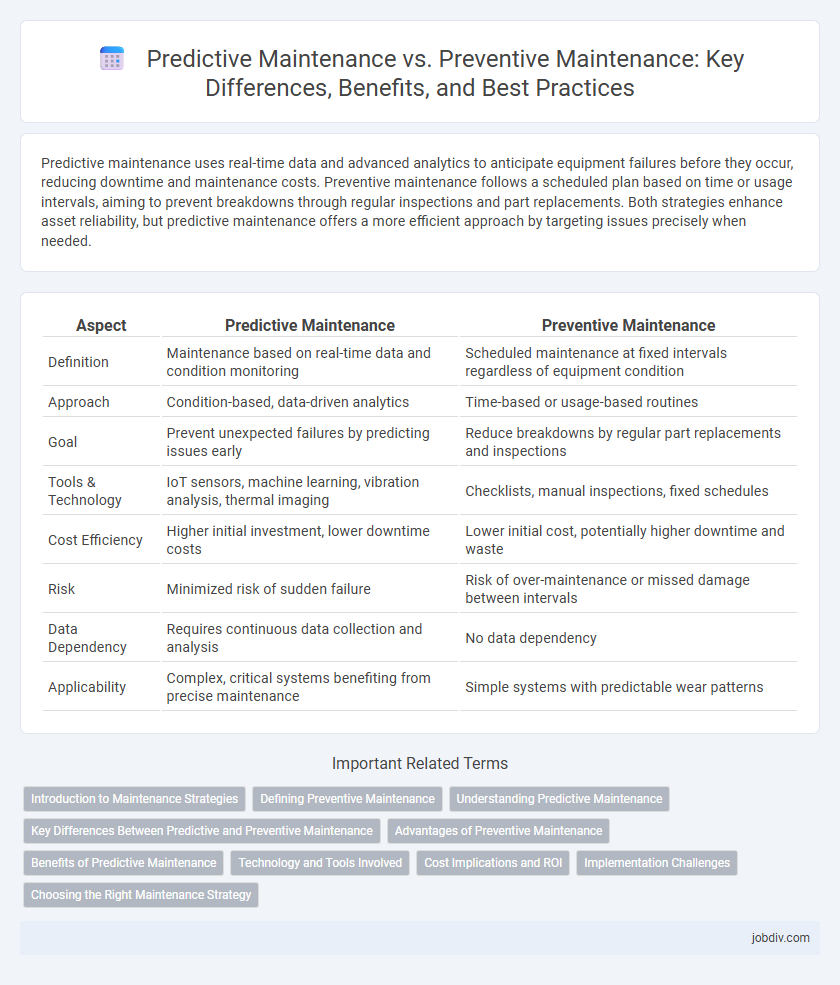

Table of Comparison

| Aspect | Predictive Maintenance | Preventive Maintenance |

|---|---|---|

| Definition | Maintenance based on real-time data and condition monitoring | Scheduled maintenance at fixed intervals regardless of equipment condition |

| Approach | Condition-based, data-driven analytics | Time-based or usage-based routines |

| Goal | Prevent unexpected failures by predicting issues early | Reduce breakdowns by regular part replacements and inspections |

| Tools & Technology | IoT sensors, machine learning, vibration analysis, thermal imaging | Checklists, manual inspections, fixed schedules |

| Cost Efficiency | Higher initial investment, lower downtime costs | Lower initial cost, potentially higher downtime and waste |

| Risk | Minimized risk of sudden failure | Risk of over-maintenance or missed damage between intervals |

| Data Dependency | Requires continuous data collection and analysis | No data dependency |

| Applicability | Complex, critical systems benefiting from precise maintenance | Simple systems with predictable wear patterns |

Introduction to Maintenance Strategies

Predictive maintenance utilizes real-time data and condition-monitoring technologies such as vibration analysis and thermal imaging to anticipate equipment failures before they occur, optimizing maintenance schedules and reducing downtime. Preventive maintenance involves regularly scheduled inspections and part replacements based on time or usage intervals to prevent unexpected breakdowns, often relying on manufacturer recommendations and historical data. Selecting the appropriate strategy depends on factors like equipment criticality, operational costs, and available monitoring technologies within the maintenance framework.

Defining Preventive Maintenance

Preventive maintenance involves scheduled inspections and servicing of equipment at regular intervals to reduce the likelihood of unexpected failures and extend asset lifespan. This strategy relies on fixed time-based or usage-based triggers, such as replacing parts every six months or after a certain number of operating hours. By systematically maintaining assets before defects occur, preventive maintenance helps to minimize downtime and optimize operational efficiency.

Understanding Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics, such as IoT sensors and machine learning algorithms, to forecast equipment failures before they occur, minimizing unplanned downtime and reducing maintenance costs. Unlike preventive maintenance, which relies on scheduled inspections and routine part replacements regardless of actual asset condition, predictive maintenance optimizes maintenance scheduling based on the actual health and performance metrics of machinery. This data-driven approach improves asset reliability, extends equipment lifespan, and enhances operational efficiency by targeting specific issues only when necessary.

Key Differences Between Predictive and Preventive Maintenance

Predictive maintenance relies on real-time data and advanced analytics to forecast equipment failures, enabling maintenance only when necessary, while preventive maintenance follows a scheduled routine based on time or usage intervals regardless of equipment condition. Predictive maintenance reduces downtime and maintenance costs by addressing issues before failure, whereas preventive maintenance may lead to unnecessary maintenance activities and higher operational expenses. The key difference lies in predictive maintenance's condition-based approach versus preventive maintenance's time-based strategy.

Advantages of Preventive Maintenance

Preventive maintenance minimizes unexpected equipment failures by scheduling regular inspections and servicing based on manufacturer recommendations and equipment usage data. This approach reduces downtime and extends the lifespan of machinery through systematic upkeep, preventing major breakdowns before they occur. Compared to predictive maintenance, preventive maintenance requires less reliance on real-time data analytics, making it easier to implement across various industries with existing maintenance protocols.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to precisely forecast equipment failures, reducing unplanned downtime and maintenance costs. It enhances asset longevity by addressing issues only when necessary, optimizing resource allocation and minimizing unnecessary part replacements. This approach improves operational efficiency through targeted interventions, ensuring higher equipment reliability compared to traditional preventive maintenance schedules.

Technology and Tools Involved

Predictive maintenance leverages advanced technologies like IoT sensors, machine learning algorithms, and real-time data analytics to monitor equipment condition and predict failures before they occur. Preventive maintenance relies on scheduled inspections, manual checklists, and routine servicing tools to perform upkeep based on time or usage intervals. Integrating AI-driven diagnostics and cloud-based platforms distinguishes predictive maintenance by enabling precise interventions, whereas preventive maintenance uses traditional tools and historical data for maintenance planning.

Cost Implications and ROI

Predictive maintenance leverages real-time data and advanced analytics to anticipate equipment failures, reducing unexpected downtime and optimizing maintenance schedules, which significantly lowers long-term operational costs. Preventive maintenance follows a fixed schedule regardless of actual equipment condition, often leading to unnecessary part replacements and higher labor costs, which can diminish return on investment. Companies investing in predictive maintenance typically realize improved ROI due to extended equipment lifespan and enhanced asset reliability, despite potentially higher initial technology expenditures.

Implementation Challenges

Predictive maintenance implementation faces challenges such as high initial costs for sensor installation and data analytics infrastructure, alongside the need for skilled personnel to interpret complex machine data accurately. Preventive maintenance, while easier to schedule and manage, often suffers from inefficiencies due to over-maintenance and unexpected equipment failure between scheduled services. Both approaches require integration with existing asset management systems, presenting difficulties in data compatibility and real-time monitoring capabilities.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy involves evaluating equipment criticality, failure patterns, and cost-effectiveness between predictive and preventive maintenance. Predictive maintenance uses real-time data and condition monitoring to predict failures and optimize service intervals, reducing downtime and extending asset life. Preventive maintenance follows scheduled inspections and replacements regardless of equipment condition, ensuring consistent reliability but potentially leading to unnecessary maintenance costs.

Predictive Maintenance vs Preventive Maintenance Infographic

jobdiv.com

jobdiv.com