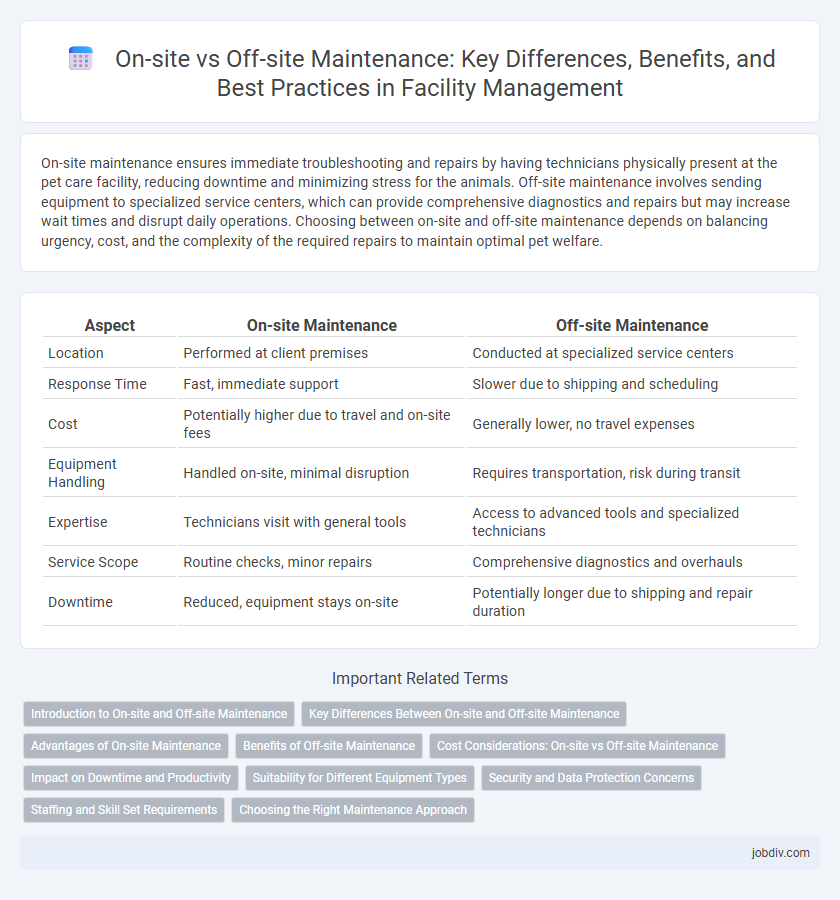

On-site maintenance ensures immediate troubleshooting and repairs by having technicians physically present at the pet care facility, reducing downtime and minimizing stress for the animals. Off-site maintenance involves sending equipment to specialized service centers, which can provide comprehensive diagnostics and repairs but may increase wait times and disrupt daily operations. Choosing between on-site and off-site maintenance depends on balancing urgency, cost, and the complexity of the required repairs to maintain optimal pet welfare.

Table of Comparison

| Aspect | On-site Maintenance | Off-site Maintenance |

|---|---|---|

| Location | Performed at client premises | Conducted at specialized service centers |

| Response Time | Fast, immediate support | Slower due to shipping and scheduling |

| Cost | Potentially higher due to travel and on-site fees | Generally lower, no travel expenses |

| Equipment Handling | Handled on-site, minimal disruption | Requires transportation, risk during transit |

| Expertise | Technicians visit with general tools | Access to advanced tools and specialized technicians |

| Service Scope | Routine checks, minor repairs | Comprehensive diagnostics and overhauls |

| Downtime | Reduced, equipment stays on-site | Potentially longer due to shipping and repair duration |

Introduction to On-site and Off-site Maintenance

On-site maintenance involves technicians performing repairs and servicing directly at the equipment's location, ensuring immediate response and minimal downtime. Off-site maintenance requires transporting equipment to a specialized facility where advanced diagnostics and repairs are conducted under controlled conditions. Choosing between on-site and off-site maintenance depends on factors such as equipment complexity, urgency, and cost efficiency.

Key Differences Between On-site and Off-site Maintenance

On-site maintenance involves technicians performing repairs or servicing directly at the location of the equipment, enabling immediate response and minimizing downtime. Off-site maintenance requires sending equipment to a dedicated service center, offering specialized tools and controlled environments but potentially increasing turnaround time due to transportation. Key differences include response time, cost efficiency, access to specialized resources, and the impact on operational continuity.

Advantages of On-site Maintenance

On-site maintenance offers immediate technical support, minimizing equipment downtime and accelerating issue resolution. It enables direct interaction with machinery and systems, allowing technicians to perform thorough inspections and real-time troubleshooting. Proximity to the site enhances efficiency in urgent repairs, ensuring continuous operational productivity.

Benefits of Off-site Maintenance

Off-site maintenance offers enhanced flexibility by allowing technicians to work in a controlled environment, reducing downtime caused by site-specific disruptions. Centralized resources and specialized equipment improve repair quality and efficiency, leading to faster turnaround times. It also minimizes on-site safety risks and operational interruptions, optimizing overall maintenance workflows.

Cost Considerations: On-site vs Off-site Maintenance

On-site maintenance often incurs higher costs due to technician travel expenses, equipment downtime, and the need for specialized tools and spare parts on location. Off-site maintenance can reduce expenses by centralizing repairs in specialized facilities, optimizing resource allocation, and minimizing operational interruptions. Companies frequently compare labor rates, logistical expenses, and turnaround times to determine the most cost-effective maintenance strategy.

Impact on Downtime and Productivity

On-site maintenance minimizes downtime by enabling immediate repairs and real-time troubleshooting, which sustains continuous productivity. Off-site maintenance often requires equipment removal and transportation, leading to extended downtime and potential disruption of operations. The choice between on-site and off-site maintenance significantly impacts overall operational efficiency and workforce productivity.

Suitability for Different Equipment Types

On-site maintenance is ideal for large, complex equipment requiring immediate attention and minimal downtime, such as manufacturing machinery and heavy industrial systems. Off-site maintenance suits smaller, portable devices like laptops and medical equipment that can be transported without disrupting operations. Selecting the appropriate maintenance type ensures efficient equipment care tailored to specific operational needs and technical demands.

Security and Data Protection Concerns

On-site maintenance ensures direct control over data security by restricting access to sensitive information within the company premises, minimizing risks of data breaches during service. Off-site maintenance poses challenges in securing data transmission and storage, requiring robust encryption and strict compliance with data protection regulations to prevent unauthorized access. Businesses prioritizing confidentiality often prefer on-site solutions to maintain tighter oversight of security protocols and safeguard proprietary information.

Staffing and Skill Set Requirements

On-site maintenance requires a team with diverse technical skills capable of handling urgent repairs and routine checks directly at the facility, ensuring immediate response times. Off-site maintenance focuses on specialized technicians with advanced expertise who diagnose and resolve complex issues remotely or at a dedicated repair center. Staffing for on-site roles prioritizes versatility and quick problem-solving, while off-site maintenance demands in-depth knowledge and the ability to manage equipment transport and logistics effectively.

Choosing the Right Maintenance Approach

Choosing the right maintenance approach depends on factors such as equipment criticality, downtime tolerance, and available technical expertise. On-site maintenance enables rapid response and minimized downtime for critical machinery, while off-site maintenance offers cost savings and specialized expertise for non-urgent repairs. Evaluating operational priorities and resource availability ensures optimal balance between maintenance efficiency and overall productivity.

On-site Maintenance vs Off-site Maintenance Infographic

jobdiv.com

jobdiv.com