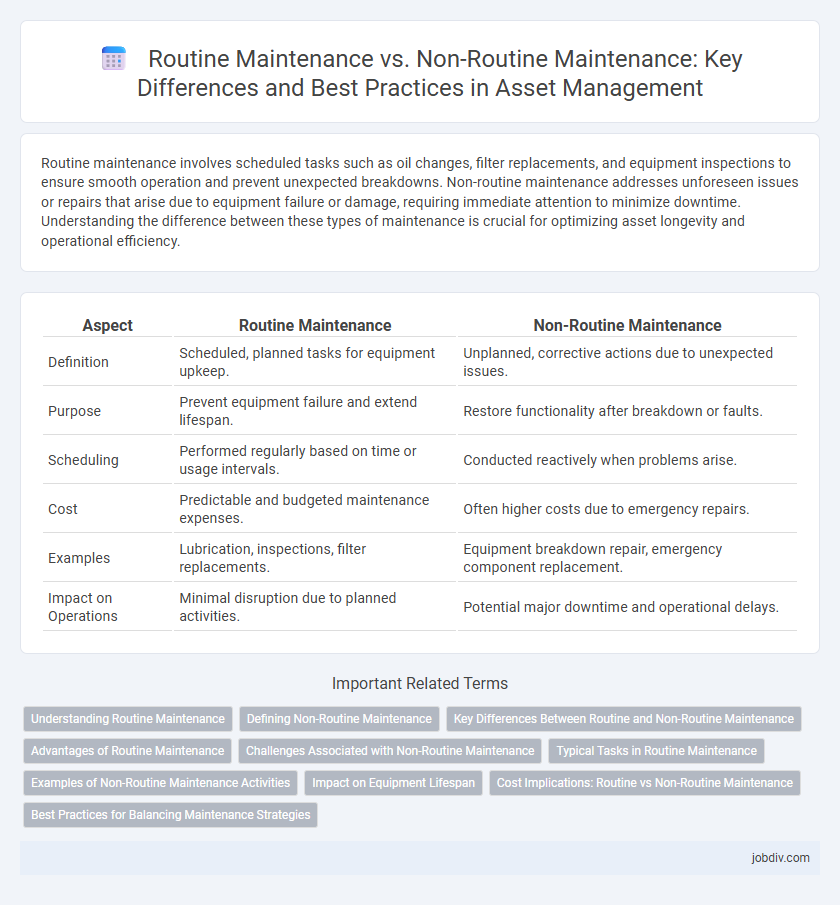

Routine maintenance involves scheduled tasks such as oil changes, filter replacements, and equipment inspections to ensure smooth operation and prevent unexpected breakdowns. Non-routine maintenance addresses unforeseen issues or repairs that arise due to equipment failure or damage, requiring immediate attention to minimize downtime. Understanding the difference between these types of maintenance is crucial for optimizing asset longevity and operational efficiency.

Table of Comparison

| Aspect | Routine Maintenance | Non-Routine Maintenance |

|---|---|---|

| Definition | Scheduled, planned tasks for equipment upkeep. | Unplanned, corrective actions due to unexpected issues. |

| Purpose | Prevent equipment failure and extend lifespan. | Restore functionality after breakdown or faults. |

| Scheduling | Performed regularly based on time or usage intervals. | Conducted reactively when problems arise. |

| Cost | Predictable and budgeted maintenance expenses. | Often higher costs due to emergency repairs. |

| Examples | Lubrication, inspections, filter replacements. | Equipment breakdown repair, emergency component replacement. |

| Impact on Operations | Minimal disruption due to planned activities. | Potential major downtime and operational delays. |

Understanding Routine Maintenance

Routine maintenance involves regularly scheduled tasks designed to prevent equipment failure and ensure optimal performance, such as inspections, lubrication, and cleaning. This proactive approach minimizes downtime and extends the lifespan of machinery by addressing wear and tear before serious issues arise. Consistent execution of routine maintenance enhances reliability, safety, and operational efficiency in industrial and commercial settings.

Defining Non-Routine Maintenance

Non-routine maintenance involves unexpected repairs and interventions required to address sudden equipment failures or malfunctions that disrupt normal operations. Unlike routine maintenance, which follows a scheduled plan to prevent issues, non-routine maintenance demands immediate attention and specialized troubleshooting to restore functionality. Effective management of non-routine maintenance minimizes downtime and prevents extended production losses in industrial and commercial settings.

Key Differences Between Routine and Non-Routine Maintenance

Routine maintenance involves scheduled, repetitive tasks such as inspections, lubrication, and adjustments to prevent equipment failure and ensure operational efficiency. Non-routine maintenance occurs in response to unexpected breakdowns or malfunctions requiring immediate repair or troubleshooting to restore functionality. Key differences include predictability, with routine maintenance being planned and non-routine being reactive, and their impact on downtime, as routine reduces unplanned outages while non-routine often causes significant disruptions.

Advantages of Routine Maintenance

Routine maintenance improves equipment reliability by preventing unexpected breakdowns and extending asset lifespan. It ensures consistent operational efficiency, reduces emergency repair costs, and supports safety compliance in industrial environments. Systematic scheduling of inspections and minor repairs minimizes downtime and optimizes resource allocation.

Challenges Associated with Non-Routine Maintenance

Non-routine maintenance presents challenges such as unpredictable equipment failures, which require immediate diagnosis and repair without prior preparation. Limited availability of specialized tools and spare parts often leads to extended downtime, impacting overall productivity. Skilled labor shortages and the complexity of unforeseen issues further complicate timely and effective response during non-routine maintenance events.

Typical Tasks in Routine Maintenance

Typical tasks in routine maintenance include regularly inspecting equipment, performing lubrication, replacing filters, and cleaning components to prevent breakdowns and ensure optimal operation. Routine maintenance also involves scheduled adjustments, calibration of instruments, and minor repairs to extend machinery lifespan. These proactive tasks reduce downtime and enhance overall system reliability compared to non-routine maintenance, which addresses unexpected failures.

Examples of Non-Routine Maintenance Activities

Non-routine maintenance activities include emergency repairs such as fixing unexpected equipment breakdowns, conducting major overhauls of machinery, and addressing safety hazards like gas leaks or structural damage. These tasks require immediate attention and specialized skills beyond scheduled inspections or minor adjustments typical of routine maintenance. Examples also include installing upgrades or modifications to improve system performance and comply with new regulations.

Impact on Equipment Lifespan

Routine maintenance, including scheduled inspections, lubrication, and parts replacement, significantly extends equipment lifespan by preventing wear and identifying issues early. Non-routine maintenance, often reactive and prompted by unexpected failures, can lead to increased downtime and accelerated equipment degradation. Consistent execution of routine maintenance optimizes asset reliability and reduces the likelihood of costly repairs, thereby preserving operational efficiency and investment value.

Cost Implications: Routine vs Non-Routine Maintenance

Routine maintenance involves scheduled, preventive actions that minimize equipment breakdowns and reduce long-term repair expenses, leading to more predictable budgeting. Non-routine maintenance, triggered by unexpected failures, incurs higher costs due to urgent repairs, potential downtime, and often requires more expensive parts or labor. Prioritizing routine maintenance effectively controls operational expenses and enhances asset lifespan while non-routine maintenance can result in substantial financial strain and production losses.

Best Practices for Balancing Maintenance Strategies

Balancing routine maintenance and non-routine maintenance requires a strategic approach that prioritizes asset reliability and cost efficiency. Implementing predictive analytics and condition monitoring helps schedule routine tasks proactively while swiftly addressing unexpected repairs through non-routine interventions. Optimizing maintenance schedules based on equipment criticality and operational data ensures minimal downtime and extends asset lifespan.

Routine Maintenance vs Non-Routine Maintenance Infographic

jobdiv.com

jobdiv.com