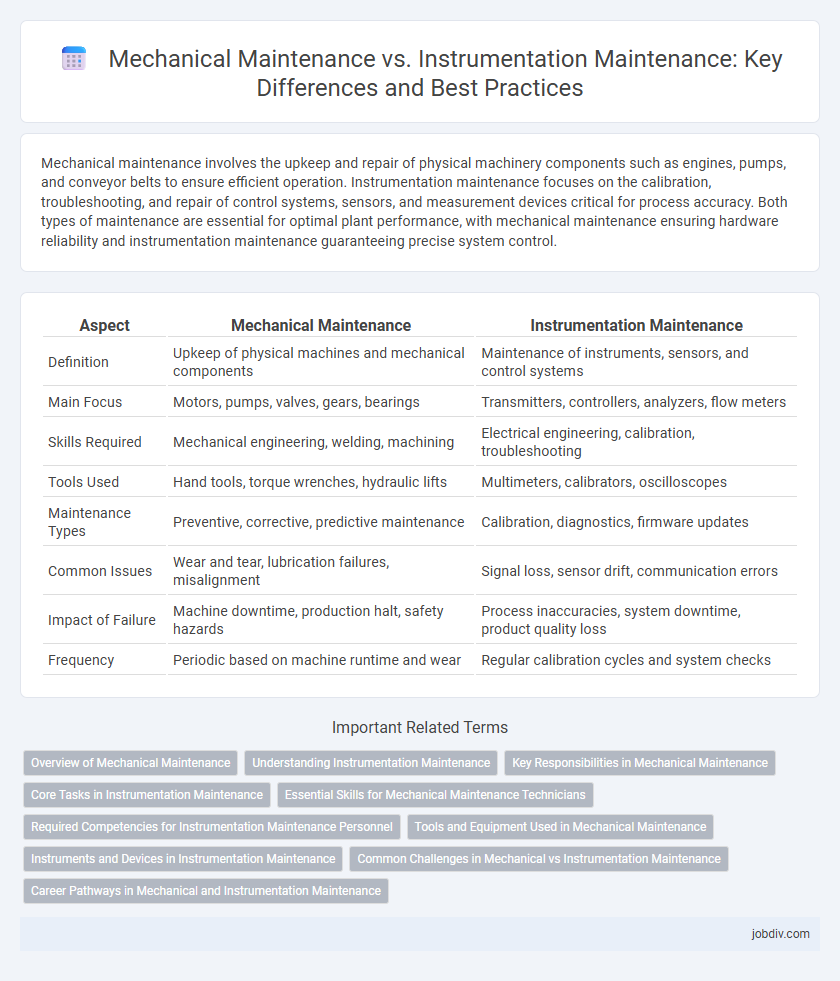

Mechanical maintenance involves the upkeep and repair of physical machinery components such as engines, pumps, and conveyor belts to ensure efficient operation. Instrumentation maintenance focuses on the calibration, troubleshooting, and repair of control systems, sensors, and measurement devices critical for process accuracy. Both types of maintenance are essential for optimal plant performance, with mechanical maintenance ensuring hardware reliability and instrumentation maintenance guaranteeing precise system control.

Table of Comparison

| Aspect | Mechanical Maintenance | Instrumentation Maintenance |

|---|---|---|

| Definition | Upkeep of physical machines and mechanical components | Maintenance of instruments, sensors, and control systems |

| Main Focus | Motors, pumps, valves, gears, bearings | Transmitters, controllers, analyzers, flow meters |

| Skills Required | Mechanical engineering, welding, machining | Electrical engineering, calibration, troubleshooting |

| Tools Used | Hand tools, torque wrenches, hydraulic lifts | Multimeters, calibrators, oscilloscopes |

| Maintenance Types | Preventive, corrective, predictive maintenance | Calibration, diagnostics, firmware updates |

| Common Issues | Wear and tear, lubrication failures, misalignment | Signal loss, sensor drift, communication errors |

| Impact of Failure | Machine downtime, production halt, safety hazards | Process inaccuracies, system downtime, product quality loss |

| Frequency | Periodic based on machine runtime and wear | Regular calibration cycles and system checks |

Overview of Mechanical Maintenance

Mechanical maintenance focuses on the upkeep and repair of physical equipment such as motors, pumps, and conveyor systems to ensure operational efficiency and prevent downtime. It involves preventive, predictive, and corrective maintenance strategies centered on mechanical components including bearings, gears, and belts. This type of maintenance prioritizes lubrication, alignment, and wear detection to extend equipment lifespan and improve reliability.

Understanding Instrumentation Maintenance

Instrumentation maintenance involves the calibration, repair, and upkeep of sensors, controllers, and other monitoring devices critical for automated process control systems, ensuring accurate data collection and system reliability. Unlike mechanical maintenance, which primarily addresses physical components like gears and engines, instrumentation maintenance emphasizes the precision and functionality of electronic and digital instruments. Proper instrumentation maintenance minimizes downtime, optimizes process efficiency, and enhances overall plant safety by preventing faulty readings and equipment failures.

Key Responsibilities in Mechanical Maintenance

Mechanical maintenance involves the inspection, repair, and servicing of equipment such as pumps, motors, conveyors, and engines to ensure optimal performance and minimize downtime. Key responsibilities include lubrication, alignment, calibration, and replacement of worn mechanical parts to prevent failures and extend machinery lifespan. Skilled technicians must also interpret mechanical drawings, diagnose faults, and perform regular preventive maintenance to maintain system reliability.

Core Tasks in Instrumentation Maintenance

Instrumentation maintenance primarily focuses on calibrating, testing, and repairing sensors, transmitters, and control systems to ensure accurate process measurements and automation. Core tasks include troubleshooting signal inconsistencies, performing firmware updates on instruments, and verifying the integrity of communication protocols within control networks. This specialized maintenance guarantees the reliability and precision of data critical for efficient plant operation and safety management.

Essential Skills for Mechanical Maintenance Technicians

Mechanical maintenance technicians require essential skills such as proficiency in reading blueprints, hands-on expertise with hydraulic and pneumatic systems, and strong mechanical troubleshooting abilities. They must possess knowledge in welding, machining, and preventive maintenance techniques to ensure the longevity of machinery. In contrast to instrumentation maintenance, which focuses on electronic calibration and control systems, mechanical maintenance prioritizes physical repairs and mechanical system optimization.

Required Competencies for Instrumentation Maintenance Personnel

Instrumentation maintenance personnel require specialized expertise in calibration, signal processing, and diagnostic troubleshooting of sensors and control systems. Proficiency in interpreting electronic schematics, familiarity with programmable logic controllers (PLCs), and knowledge of industrial communication protocols such as HART and Foundation Fieldbus are critical. Unlike mechanical maintenance, instrumentation maintenance demands not only mechanical aptitude but also advanced skills in electronics and automation technology.

Tools and Equipment Used in Mechanical Maintenance

Mechanical maintenance primarily utilizes tools such as wrenches, torque drivers, hydraulic jacks, and precision measuring instruments like calipers and micrometers to ensure the proper functioning of machinery. Equipment including pneumatic drills, grinders, and lubrication devices are essential for routine servicing and repair of mechanical components. These tools and equipment are specifically designed to handle physical parts, contrasting with the electronic testers and calibration devices used in instrumentation maintenance.

Instruments and Devices in Instrumentation Maintenance

Instrumentation maintenance focuses on the systematic calibration, testing, and repair of precision instruments and devices such as sensors, transmitters, and control valves that monitor and control industrial processes. Unlike mechanical maintenance, which primarily addresses physical machinery and moving parts, instrumentation maintenance ensures the accuracy, reliability, and functionality of electronic and electrical measurement systems. Proper upkeep of instruments minimizes downtime and enhances process efficiency through precise data acquisition and automated control.

Common Challenges in Mechanical vs Instrumentation Maintenance

Mechanical maintenance often grapples with issues such as wear and tear, alignment problems, and lubrication failures, impacting equipment longevity and performance. Instrumentation maintenance faces challenges like sensor calibration errors, signal noise, and electronic component malfunctions, which can disrupt accurate process control. Both domains require precise troubleshooting skills and timely interventions to minimize downtime and ensure operational efficiency.

Career Pathways in Mechanical and Instrumentation Maintenance

Mechanical maintenance careers often lead to roles such as maintenance technician, mechanical engineer, or maintenance supervisor, focusing on machinery repair, system diagnostics, and predictive maintenance. Instrumentation maintenance pathways typically involve becoming an instrumentation technician, control systems engineer, or calibration specialist, emphasizing the upkeep of sensors, control instruments, and automation systems. Both career tracks require strong problem-solving skills and technical expertise, offering opportunities for advancement in industrial plants, manufacturing, and energy sectors.

Mechanical Maintenance vs Instrumentation Maintenance Infographic

jobdiv.com

jobdiv.com