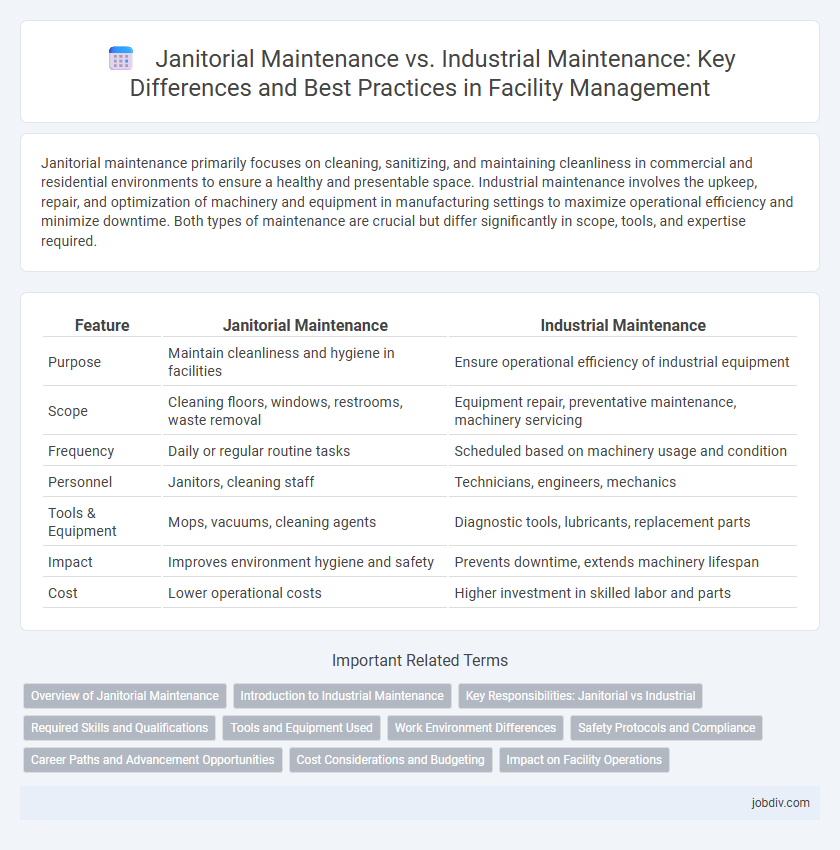

Janitorial maintenance primarily focuses on cleaning, sanitizing, and maintaining cleanliness in commercial and residential environments to ensure a healthy and presentable space. Industrial maintenance involves the upkeep, repair, and optimization of machinery and equipment in manufacturing settings to maximize operational efficiency and minimize downtime. Both types of maintenance are crucial but differ significantly in scope, tools, and expertise required.

Table of Comparison

| Feature | Janitorial Maintenance | Industrial Maintenance |

|---|---|---|

| Purpose | Maintain cleanliness and hygiene in facilities | Ensure operational efficiency of industrial equipment |

| Scope | Cleaning floors, windows, restrooms, waste removal | Equipment repair, preventative maintenance, machinery servicing |

| Frequency | Daily or regular routine tasks | Scheduled based on machinery usage and condition |

| Personnel | Janitors, cleaning staff | Technicians, engineers, mechanics |

| Tools & Equipment | Mops, vacuums, cleaning agents | Diagnostic tools, lubricants, replacement parts |

| Impact | Improves environment hygiene and safety | Prevents downtime, extends machinery lifespan |

| Cost | Lower operational costs | Higher investment in skilled labor and parts |

Overview of Janitorial Maintenance

Janitorial maintenance involves routine cleaning and upkeep activities such as sweeping, mopping, dusting, and trash removal to ensure clean and sanitary environments in commercial and residential spaces. It focuses on maintaining aesthetic appeal and hygiene, preventing the buildup of dirt and germs that could impact health and safety. This type of maintenance differs from industrial maintenance, which primarily addresses equipment repair and operational efficiency in manufacturing or production facilities.

Introduction to Industrial Maintenance

Industrial maintenance focuses on the upkeep and repair of heavy machinery, production equipment, and critical infrastructure within manufacturing and processing plants. It ensures operational efficiency, reduces downtime, and extends the lifespan of complex systems through preventive and predictive maintenance strategies. Unlike janitorial maintenance, which prioritizes cleanliness and sanitation, industrial maintenance demands specialized technical skills and knowledge of mechanical, electrical, and automation systems.

Key Responsibilities: Janitorial vs Industrial

Janitorial maintenance primarily involves cleaning, waste disposal, surface care, and restroom sanitation to ensure a hygienic environment in offices or commercial spaces. Industrial maintenance focuses on equipment inspection, machinery repair, lubrication, preventive maintenance, and troubleshooting to optimize production uptime and safety in manufacturing plants. Both require adherence to safety protocols but differ significantly in technical skill sets and tools used.

Required Skills and Qualifications

Janitorial maintenance requires skills such as effective cleaning techniques, knowledge of chemical handling, and attention to detail to ensure sanitary and safe environments, with qualifications often including custodial training or certification. Industrial maintenance demands advanced technical skills in machinery repair, electrical systems, and preventive maintenance, typically requiring certifications in mechanical or electrical trades and experience with industrial equipment. Both roles emphasize safety protocols but differ significantly in technical complexity and specialized knowledge.

Tools and Equipment Used

Janitorial maintenance primarily uses tools like brooms, mops, vacuum cleaners, and disinfectants designed for cleaning surfaces and maintaining hygiene in offices or commercial spaces. Industrial maintenance relies on specialized equipment such as hydraulic lifts, pneumatic tools, welding machines, and diagnostic instruments to repair and maintain heavy machinery and factory infrastructure. Both types of maintenance require distinct toolsets optimized for their specific environments and operational demands.

Work Environment Differences

Janitorial maintenance primarily takes place in commercial or public spaces such as offices, schools, and hospitals, where cleanliness and hygiene are critical to occupant health and comfort. Industrial maintenance occurs in manufacturing plants, factories, or heavy machinery environments, focusing on equipment reliability and operational safety. The work environment in janitorial maintenance demands attention to detailed cleaning protocols, while industrial maintenance requires technical expertise in machinery diagnostics and repair under potentially hazardous conditions.

Safety Protocols and Compliance

Janitorial maintenance prioritizes safety protocols related to chemical handling, waste disposal, and ergonomic practices to prevent workplace injuries and ensure compliance with OSHA standards. Industrial maintenance involves stricter safety measures, including lockout/tagout procedures, machine guarding, and hazardous material management to comply with industry-specific regulations such as NFPA and EPA guidelines. Both maintenance types require routine safety audits and employee training programs to uphold regulatory compliance and minimize accident risks.

Career Paths and Advancement Opportunities

Janitorial maintenance offers career paths centered around cleaning, sanitation, and basic facility upkeep, typically requiring entry-level skills with opportunities to advance into supervisory or management roles within commercial or residential settings. Industrial maintenance careers demand specialized technical expertise in equipment repair, mechanical systems, and electrical troubleshooting, leading to advanced positions such as maintenance technicians, engineers, or plant managers in manufacturing and production environments. Progression in industrial maintenance often involves certifications and technical training that enhance job stability, salary growth, and leadership roles compared to the usually lower-wage, entry-level progression in janitorial maintenance.

Cost Considerations and Budgeting

Janitorial maintenance typically involves lower labor and material costs due to routine cleaning tasks and standard supplies, making it more budget-friendly for small to medium facilities. Industrial maintenance demands higher investment in specialized skilled labor, equipment repairs, and preventive measures to avoid costly production downtime, significantly impacting operational budgets. Effective budgeting requires detailed cost analysis of direct expenses and potential long-term savings from predictive maintenance strategies tailored to each maintenance type.

Impact on Facility Operations

Janitorial maintenance ensures cleanliness, hygiene, and a safe environment, directly influencing employee productivity and customer satisfaction by preventing health hazards and maintaining aesthetic appeal. Industrial maintenance focuses on the upkeep of machinery, equipment, and infrastructure, minimizing downtime and operational disruptions that can lead to costly delays and reduced output. Both types of maintenance are critical, with janitorial efforts sustaining day-to-day facility usability and industrial maintenance preserving the core functionality and efficiency of operational systems.

Janitorial Maintenance vs Industrial Maintenance Infographic

jobdiv.com

jobdiv.com