Emergency maintenance addresses unexpected equipment failures requiring immediate repairs to prevent further damage or downtime. Scheduled maintenance involves planned inspections and servicing performed regularly to ensure optimal performance and extend the lifespan of machinery. Prioritizing scheduled maintenance reduces the likelihood of costly emergency interventions and enhances operational efficiency.

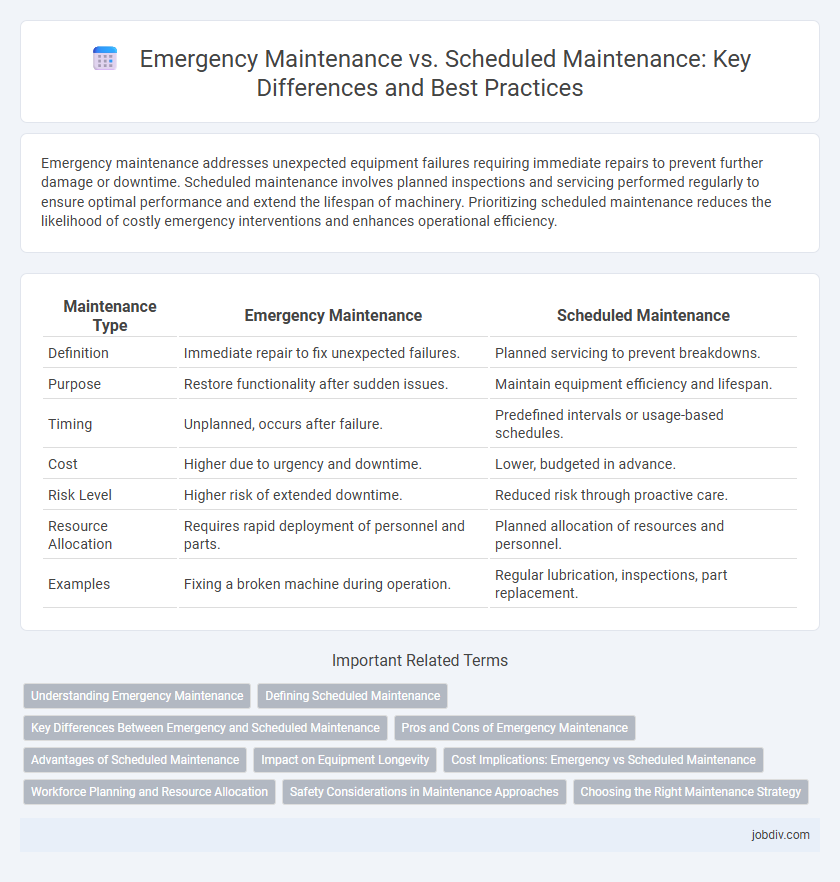

Table of Comparison

| Maintenance Type | Emergency Maintenance | Scheduled Maintenance |

|---|---|---|

| Definition | Immediate repair to fix unexpected failures. | Planned servicing to prevent breakdowns. |

| Purpose | Restore functionality after sudden issues. | Maintain equipment efficiency and lifespan. |

| Timing | Unplanned, occurs after failure. | Predefined intervals or usage-based schedules. |

| Cost | Higher due to urgency and downtime. | Lower, budgeted in advance. |

| Risk Level | Higher risk of extended downtime. | Reduced risk through proactive care. |

| Resource Allocation | Requires rapid deployment of personnel and parts. | Planned allocation of resources and personnel. |

| Examples | Fixing a broken machine during operation. | Regular lubrication, inspections, part replacement. |

Understanding Emergency Maintenance

Emergency maintenance involves immediate repairs to fix unexpected equipment failures or critical system malfunctions that disrupt operations. This type of maintenance prioritizes rapid response to prevent safety hazards, extensive downtime, or significant financial losses. Understanding when to initiate emergency maintenance helps organizations minimize operational impact and ensure quicker recovery times.

Defining Scheduled Maintenance

Scheduled maintenance involves planned, routine inspections and repairs conducted at predetermined intervals to prevent equipment failures and extend asset lifespan. This proactive approach relies on detailed maintenance schedules based on manufacturer recommendations and historical performance data. Implementing scheduled maintenance reduces unexpected downtime and optimizes operational efficiency by addressing potential issues before they escalate into emergencies.

Key Differences Between Emergency and Scheduled Maintenance

Emergency maintenance addresses unexpected equipment failures requiring immediate repair to prevent operational downtime, often incurring higher costs and resource allocation. Scheduled maintenance, performed at predetermined intervals based on manufacturer recommendations or usage patterns, aims to prevent breakdowns through routine inspection and servicing. The key differences lie in timing, predictability, cost, and impact on production continuity, with emergency maintenance being reactive and urgent, while scheduled maintenance is proactive and planned.

Pros and Cons of Emergency Maintenance

Emergency maintenance offers the advantage of immediate response to critical equipment failures, minimizing downtime and preventing extended production losses. However, it often results in higher costs due to unplanned labor, expedited parts procurement, and potential safety risks associated with rushed repairs. Unlike scheduled maintenance, emergency maintenance lacks preventive measures and can lead to unpredictable disruptions and accelerated wear of machinery.

Advantages of Scheduled Maintenance

Scheduled maintenance reduces unexpected equipment failures by allowing proactive inspections and timely repairs, ensuring continuous operational efficiency. It optimizes resource allocation by planning maintenance activities during low-demand periods, minimizing downtime and labor costs. Regularly scheduled maintenance also extends asset lifespan and enhances safety by addressing potential issues before they escalate into emergencies.

Impact on Equipment Longevity

Emergency maintenance often leads to increased wear and tear on equipment due to the urgency and the likelihood of incomplete repairs, negatively impacting equipment longevity. Scheduled maintenance, performed regularly and systematically, helps identify and address potential issues early, significantly extending the life of machinery and reducing the risk of unexpected failures. Consistent scheduled maintenance optimizes equipment performance and minimizes downtime, preserving asset value over time.

Cost Implications: Emergency vs Scheduled Maintenance

Emergency maintenance often incurs significantly higher costs due to urgent labor rates, unplanned downtime, and expedited parts shipping. Scheduled maintenance allows for budget optimization by planning resources and minimizing operational disruptions, reducing overall expenses. Investing in preventive scheduled maintenance ultimately lowers the financial risks associated with unexpected emergency repairs.

Workforce Planning and Resource Allocation

Emergency maintenance demands rapid workforce mobilization and unplanned resource allocation, often disrupting productivity and increasing operational costs. Scheduled maintenance allows for strategic workforce planning and optimized resource utilization, minimizing downtime and enhancing system reliability. Effective resource allocation in scheduled maintenance supports proactive risk management and sustains operational efficiency.

Safety Considerations in Maintenance Approaches

Emergency maintenance requires immediate action to address unexpected equipment failures, posing higher safety risks due to rushed assessments and potentially hazardous environments. Scheduled maintenance allows for thorough safety evaluations and proper preparation, reducing the likelihood of accidents and ensuring compliance with safety protocols. Prioritizing safety considerations in maintenance approaches minimizes downtime and protects personnel from injury during upkeep activities.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy involves evaluating the impact of Emergency Maintenance versus Scheduled Maintenance on operational efficiency and costs. Emergency Maintenance addresses unexpected equipment failures, minimizing downtime but often incurring higher repair expenses and safety risks. Scheduled Maintenance prevents failures through regular inspections and servicing, optimizing asset longevity and budget predictability while requiring careful planning to avoid production disruptions.

Emergency Maintenance vs Scheduled Maintenance Infographic

jobdiv.com

jobdiv.com