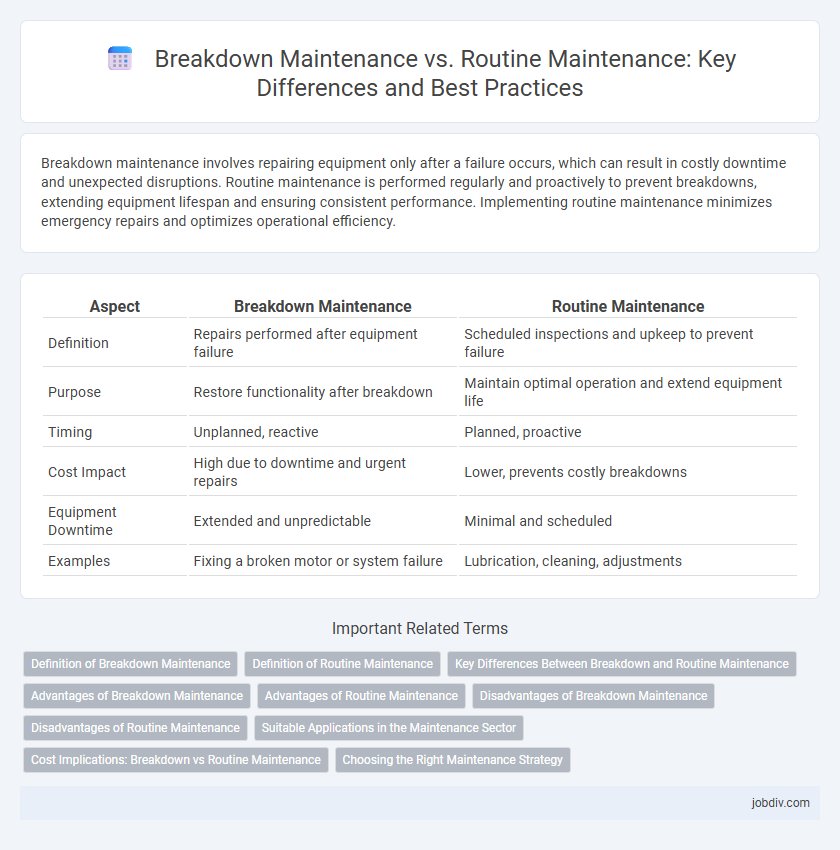

Breakdown maintenance involves repairing equipment only after a failure occurs, which can result in costly downtime and unexpected disruptions. Routine maintenance is performed regularly and proactively to prevent breakdowns, extending equipment lifespan and ensuring consistent performance. Implementing routine maintenance minimizes emergency repairs and optimizes operational efficiency.

Table of Comparison

| Aspect | Breakdown Maintenance | Routine Maintenance |

|---|---|---|

| Definition | Repairs performed after equipment failure | Scheduled inspections and upkeep to prevent failure |

| Purpose | Restore functionality after breakdown | Maintain optimal operation and extend equipment life |

| Timing | Unplanned, reactive | Planned, proactive |

| Cost Impact | High due to downtime and urgent repairs | Lower, prevents costly breakdowns |

| Equipment Downtime | Extended and unpredictable | Minimal and scheduled |

| Examples | Fixing a broken motor or system failure | Lubrication, cleaning, adjustments |

Definition of Breakdown Maintenance

Breakdown maintenance refers to the strategy of repairing equipment only after it has failed or broken down, often leading to unexpected downtime and costly repairs. This approach contrasts with routine maintenance, which involves regular inspections and preventive tasks to ensure continuous operation and reduce the likelihood of failures. Breakdown maintenance is critical in environments where immediate repairs are feasible and downtime does not severely impact production or safety.

Definition of Routine Maintenance

Routine maintenance involves regularly scheduled inspections and minor repairs designed to prevent equipment failures and extend the lifespan of machinery. This proactive approach includes lubrication, cleaning, adjustments, and calibration to ensure optimal operational efficiency and reduce unexpected breakdowns. Unlike breakdown maintenance, routine maintenance minimizes downtime and maintenance costs by addressing potential issues before they become critical.

Key Differences Between Breakdown and Routine Maintenance

Breakdown maintenance involves repairing equipment only after a failure occurs, leading to unplanned downtime and potentially higher repair costs. Routine maintenance consists of scheduled inspections and servicing to prevent equipment failures, enhancing reliability and extending asset lifespan. Key differences include the timing of interventions, cost implications, and the overall impact on operational efficiency.

Advantages of Breakdown Maintenance

Breakdown maintenance allows equipment to be repaired only when it fails, reducing unnecessary labor and maintenance costs compared to scheduled interventions. This approach minimizes downtime for machines that operate reliably over long periods without issues. It is particularly advantageous for systems with low failure rates or where maintenance costs outweigh the benefits of routine servicing.

Advantages of Routine Maintenance

Routine maintenance enhances equipment reliability by preventing unexpected breakdowns and extending asset lifespan through scheduled inspections and timely repairs. It reduces downtime and operational disruptions, leading to increased productivity and cost savings compared to costly emergency fixes associated with breakdown maintenance. Proactive care also improves safety standards and optimizes resource allocation by identifying potential issues before they escalate.

Disadvantages of Breakdown Maintenance

Breakdown maintenance often leads to unexpected equipment failures causing unplanned downtime and higher repair costs. This reactive approach increases the risk of prolonged operational disruptions and potential safety hazards. Limited predictability in breakdown maintenance can result in inefficient resource allocation and decreased overall asset lifespan.

Disadvantages of Routine Maintenance

Routine maintenance often leads to unnecessary downtime and increased labor costs due to scheduled inspections or part replacements regardless of actual equipment condition. It may cause premature replacement of components, resulting in higher material expenses and waste. This approach can divert resources from addressing urgent repairs, potentially delaying responses to critical breakdowns.

Suitable Applications in the Maintenance Sector

Breakdown Maintenance is suitable for equipment that is non-critical or where downtime does not cause significant production losses, ideal for small-scale operations with limited maintenance budgets. Routine Maintenance fits best for critical machinery requiring scheduled inspections and preventive care to avoid unexpected failures and extend equipment life. Industries with high operational demands, such as manufacturing or utilities, prioritize Routine Maintenance to ensure reliability and minimize costly breakdowns.

Cost Implications: Breakdown vs Routine Maintenance

Breakdown maintenance often incurs higher costs due to unplanned downtime, emergency repairs, and expedited parts replacement, leading to production losses. Routine maintenance, although involving regular scheduled expenses, minimizes unexpected failures and extends equipment lifespan, ultimately reducing total operational costs. Investing in routine maintenance improves budget predictability and decreases the financial risks associated with sudden breakdowns.

Choosing the Right Maintenance Strategy

Breakdown maintenance focuses on repairing equipment only after failure occurs, leading to unexpected downtime and higher costs, while routine maintenance involves scheduled inspections and servicing to prevent breakdowns. Choosing the right maintenance strategy depends on factors like equipment criticality, operational costs, and production schedules, with routine maintenance often favored for essential machinery to enhance reliability and lifespan. An optimized approach integrates condition monitoring and data analytics to balance maintenance efforts and minimize both unplanned outages and unnecessary servicing.

Breakdown Maintenance vs Routine Maintenance Infographic

jobdiv.com

jobdiv.com