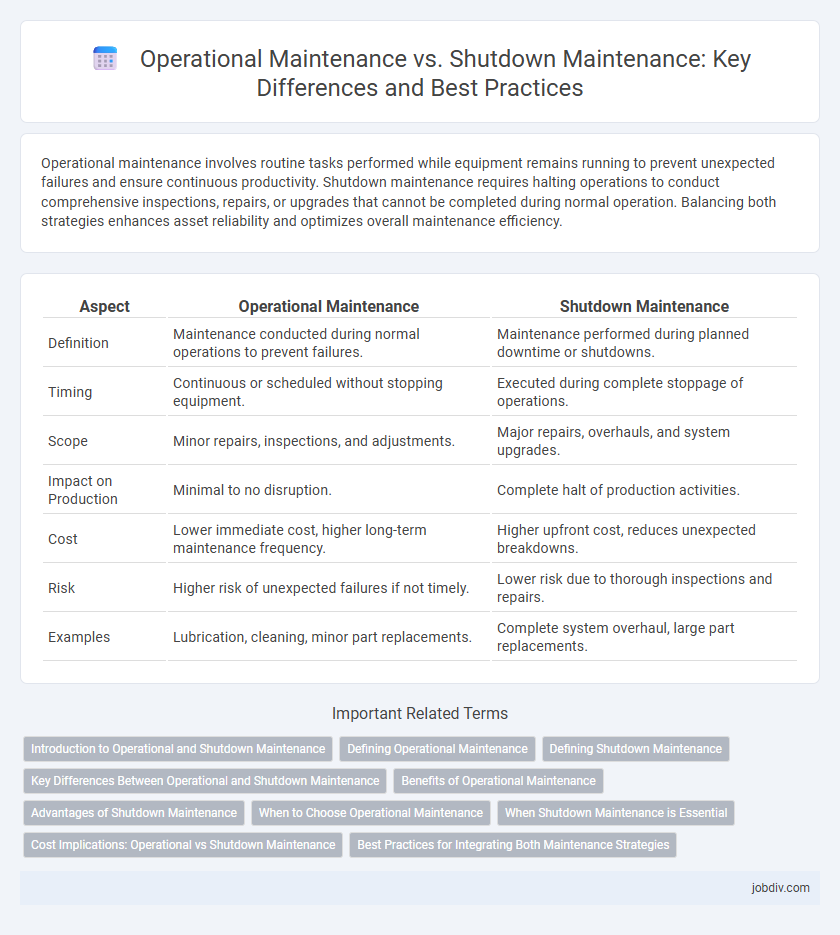

Operational maintenance involves routine tasks performed while equipment remains running to prevent unexpected failures and ensure continuous productivity. Shutdown maintenance requires halting operations to conduct comprehensive inspections, repairs, or upgrades that cannot be completed during normal operation. Balancing both strategies enhances asset reliability and optimizes overall maintenance efficiency.

Table of Comparison

| Aspect | Operational Maintenance | Shutdown Maintenance |

|---|---|---|

| Definition | Maintenance conducted during normal operations to prevent failures. | Maintenance performed during planned downtime or shutdowns. |

| Timing | Continuous or scheduled without stopping equipment. | Executed during complete stoppage of operations. |

| Scope | Minor repairs, inspections, and adjustments. | Major repairs, overhauls, and system upgrades. |

| Impact on Production | Minimal to no disruption. | Complete halt of production activities. |

| Cost | Lower immediate cost, higher long-term maintenance frequency. | Higher upfront cost, reduces unexpected breakdowns. |

| Risk | Higher risk of unexpected failures if not timely. | Lower risk due to thorough inspections and repairs. |

| Examples | Lubrication, cleaning, minor part replacements. | Complete system overhaul, large part replacements. |

Introduction to Operational and Shutdown Maintenance

Operational maintenance involves routine activities performed while equipment is running to ensure continuous performance and prevent unexpected breakdowns. Shutdown maintenance requires planned halts of operations to conduct extensive repairs, inspections, or upgrades that cannot be performed during normal operation. Both maintenance types are critical for optimizing asset reliability, safety, and longevity in industrial environments.

Defining Operational Maintenance

Operational maintenance involves routine activities performed to ensure continuous and efficient equipment performance without halting production. This type of maintenance includes inspections, lubrication, minor repairs, and adjustments carried out while machinery remains operational. It minimizes downtime and extends asset lifespan by addressing wear and tear before failures occur.

Defining Shutdown Maintenance

Shutdown maintenance involves halting equipment or entire systems to perform extensive repairs, upgrades, or inspections that cannot be safely or effectively conducted during normal operations. This type of maintenance is scheduled to minimize downtime and often targets critical components requiring thorough assessment and refurbishment. Operational maintenance, by contrast, occurs during regular functioning to address routine servicing and minor repairs without stopping production.

Key Differences Between Operational and Shutdown Maintenance

Operational maintenance involves ongoing, routine tasks that keep equipment and systems running efficiently without interrupting production, focusing on preventive measures to avoid unexpected breakdowns. Shutdown maintenance occurs during planned downtime, enabling thorough inspections, repairs, and upgrades that cannot be performed during normal operations. Key differences include the timing and scope of activities, with operational maintenance emphasizing continuous upkeep and shutdown maintenance allowing more extensive, intensive interventions.

Benefits of Operational Maintenance

Operational maintenance enhances equipment reliability by performing regular inspections and minor repairs during normal production, reducing unexpected breakdowns and costly downtime. It improves safety by identifying potential hazards early, ensuring continuous compliance with safety standards. Proactive operational maintenance extends asset lifespan and optimizes maintenance budgets through timely interventions rather than costly shutdown repairs.

Advantages of Shutdown Maintenance

Shutdown maintenance offers the advantage of allowing comprehensive inspections and repairs that are not possible during regular operations, ensuring equipment reliability and safety. It minimizes the risk of unexpected breakdowns by addressing potential issues thoroughly while the system is offline. This proactive approach extends the lifespan of machinery and optimizes long-term operational efficiency.

When to Choose Operational Maintenance

Operational maintenance is ideal when equipment must remain functional without interruption, ensuring continuous production and minimizing downtime costs. It is best chosen for routine inspections, minor repairs, and preventive tasks that can be performed while machinery is active. Selecting operational maintenance optimizes asset availability and reduces the risk of unexpected failures in critical processes.

When Shutdown Maintenance is Essential

Shutdown maintenance is essential when equipment requires extensive repairs or upgrades that cannot be safely performed during normal operations, such as major overhauls or system replacements. It ensures worker safety and prevents operational hazards by halting production and allowing thorough inspections and corrections. This type of maintenance is critical for maintaining long-term equipment reliability and meeting regulatory compliance standards.

Cost Implications: Operational vs Shutdown Maintenance

Operational maintenance typically incurs higher ongoing labor and material costs due to continuous monitoring and minor repairs during regular production. Shutdown maintenance, while involving significant short-term expenses related to equipment downtime and intensive repair work, often results in lower long-term costs by preventing unexpected failures. Evaluating the total cost of ownership, including potential production losses and repair efficiency, highlights shutdown maintenance as more cost-effective for critical asset longevity.

Best Practices for Integrating Both Maintenance Strategies

Operational maintenance ensures continuous equipment functionality through routine inspections, minor repairs, and predictive monitoring, minimizing unplanned downtime and enhancing asset lifespan. Shutdown maintenance allows comprehensive inspection, extensive repairs, and upgrades during planned stoppages, addressing issues unattainable during operations. Integrating both strategies requires data-driven scheduling, cross-functional coordination, and leveraging IoT analytics to optimize maintenance windows, balance costs, and improve overall plant reliability.

Operational Maintenance vs Shutdown Maintenance Infographic

jobdiv.com

jobdiv.com