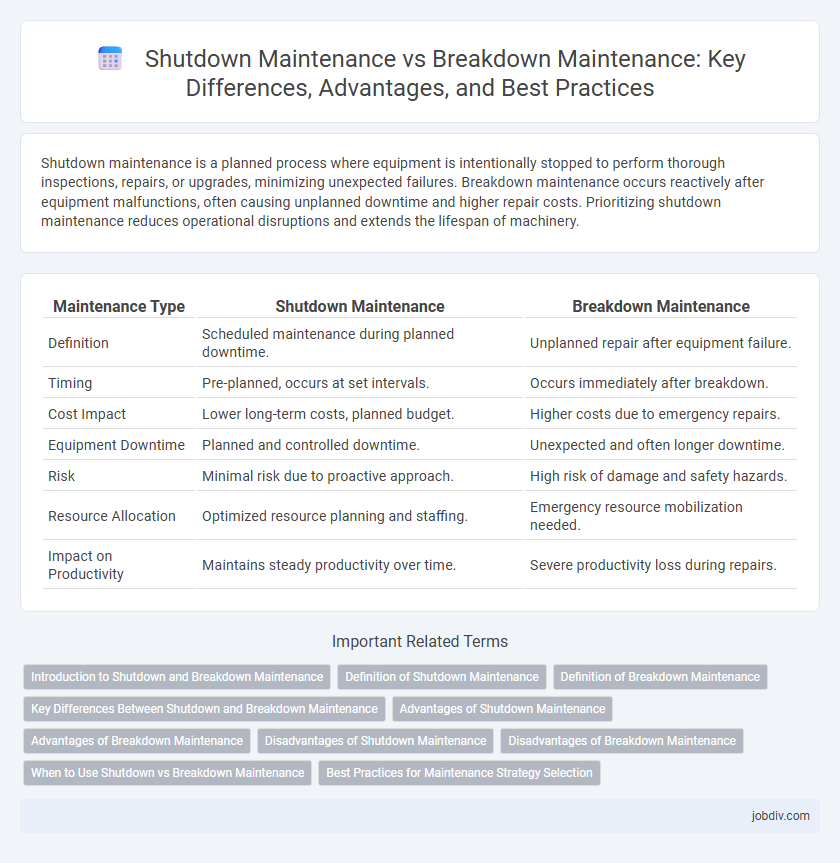

Shutdown maintenance is a planned process where equipment is intentionally stopped to perform thorough inspections, repairs, or upgrades, minimizing unexpected failures. Breakdown maintenance occurs reactively after equipment malfunctions, often causing unplanned downtime and higher repair costs. Prioritizing shutdown maintenance reduces operational disruptions and extends the lifespan of machinery.

Table of Comparison

| Maintenance Type | Shutdown Maintenance | Breakdown Maintenance |

|---|---|---|

| Definition | Scheduled maintenance during planned downtime. | Unplanned repair after equipment failure. |

| Timing | Pre-planned, occurs at set intervals. | Occurs immediately after breakdown. |

| Cost Impact | Lower long-term costs, planned budget. | Higher costs due to emergency repairs. |

| Equipment Downtime | Planned and controlled downtime. | Unexpected and often longer downtime. |

| Risk | Minimal risk due to proactive approach. | High risk of damage and safety hazards. |

| Resource Allocation | Optimized resource planning and staffing. | Emergency resource mobilization needed. |

| Impact on Productivity | Maintains steady productivity over time. | Severe productivity loss during repairs. |

Introduction to Shutdown and Breakdown Maintenance

Shutdown maintenance involves planning and scheduling downtime to perform comprehensive inspections, repairs, and upgrades, ensuring equipment reliability and preventing unexpected failures. Breakdown maintenance, also known as reactive maintenance, occurs after equipment failure, focusing on immediate repairs to restore functionality and minimize operational disruption. Understanding both strategies helps optimize maintenance efficiency and balance cost, safety, and production demands.

Definition of Shutdown Maintenance

Shutdown maintenance is a planned and scheduled process where operations are halted to perform comprehensive inspections, repairs, and replacements on equipment or systems. This proactive approach aims to prevent unexpected failures by addressing potential issues during a controlled downtime. Shutdown maintenance contrasts with breakdown maintenance, which occurs reactively after equipment failure disrupts production.

Definition of Breakdown Maintenance

Breakdown maintenance refers to the repair and restoration of equipment only after a failure or malfunction has occurred, resulting in unplanned downtime. This reactive approach contrasts with shutdown maintenance, which involves scheduled, planned activities to prevent breakdowns during designated downtime periods. Breakdown maintenance can lead to increased repair costs and production losses due to unexpected equipment failures.

Key Differences Between Shutdown and Breakdown Maintenance

Shutdown maintenance involves planned, scheduled downtime to inspect, repair, or upgrade equipment, minimizing unexpected disruptions. Breakdown maintenance occurs reactively when equipment fails, requiring immediate repairs to restore functionality, often resulting in extended downtime and higher costs. Key differences include the proactive nature and cost control of shutdown maintenance versus the reactive, costly, and disruptive characteristics of breakdown maintenance.

Advantages of Shutdown Maintenance

Shutdown maintenance allows for comprehensive inspection and repair of all equipment, minimizing unexpected breakdowns and enhancing overall system reliability. Scheduled shutdowns enable better resource allocation and workforce planning, reducing overtime costs and increasing efficiency. This proactive approach extends machinery lifespan and improves safety by addressing potential issues before they escalate.

Advantages of Breakdown Maintenance

Breakdown maintenance allows for immediate repair only when equipment fails, minimizing unnecessary service interruptions and reducing routine maintenance costs. This reactive approach extends the useful life of components by avoiding premature replacement and focuses resources solely on actual failures. Operational downtime can be optimized by quickly addressing urgent repairs without over-allocating maintenance efforts.

Disadvantages of Shutdown Maintenance

Shutdown maintenance involves planned stoppages that halt operations entirely, leading to significant production losses and revenue interruption. The extensive downtime can disrupt supply chains and delay delivery schedules, impacting overall business performance. High labor and resource costs are incurred due to the concentrated effort required during the shutdown period, reducing operational efficiency.

Disadvantages of Breakdown Maintenance

Breakdown maintenance leads to unexpected equipment failures causing costly production downtime and urgent repair expenses. This reactive approach often results in extended outages and higher risk of secondary damage to machinery. Furthermore, it lacks preventive measures, increasing overall maintenance costs and reducing equipment lifespan.

When to Use Shutdown vs Breakdown Maintenance

Shutdown maintenance is ideal for scheduled, preventive tasks requiring complete system downtime to ensure thorough inspection and repair, minimizing unexpected failures. Breakdown maintenance is suitable for emergency repairs triggered by sudden equipment failure, prioritizing quick restoration over planned servicing. Use shutdown maintenance in controlled environments to plan downtime strategically, while breakdown maintenance fits unpredictable scenarios needing immediate intervention.

Best Practices for Maintenance Strategy Selection

Shutdown maintenance involves planned downtime scheduled to perform comprehensive inspections, repairs, and replacements, minimizing unexpected failures. Breakdown maintenance occurs only after equipment failure, often leading to unplanned outages and higher repair costs. Best practices for maintenance strategy selection prioritize predictive analytics, cost-benefit analysis, and critical equipment assessment to balance operational efficiency and risk management effectively.

Shutdown Maintenance vs Breakdown Maintenance Infographic

jobdiv.com

jobdiv.com