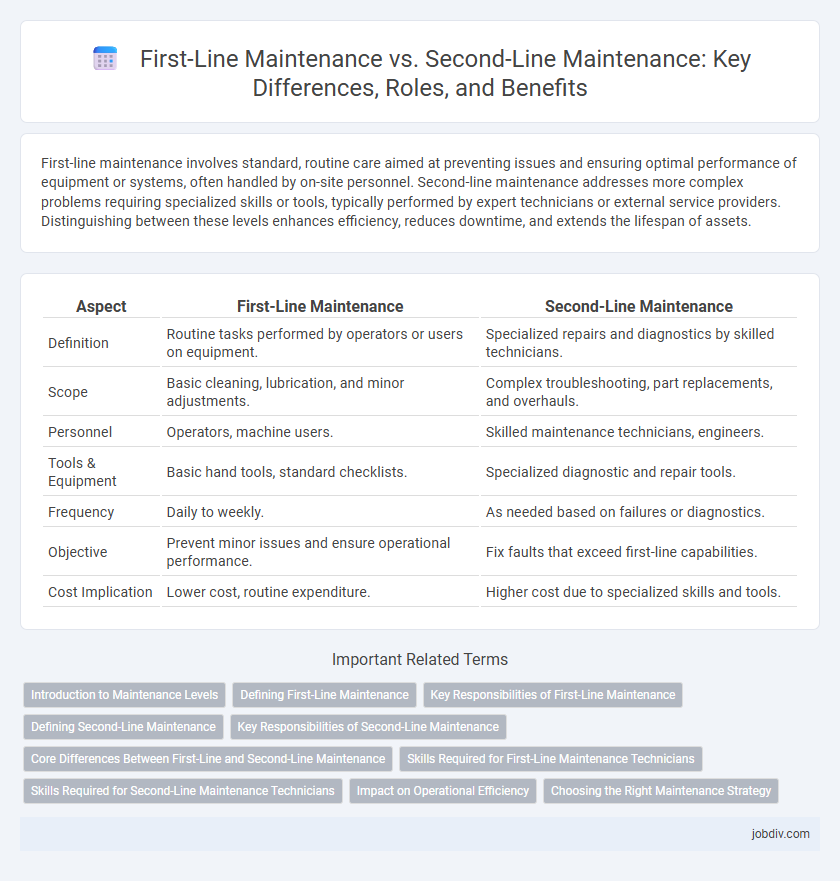

First-line maintenance involves standard, routine care aimed at preventing issues and ensuring optimal performance of equipment or systems, often handled by on-site personnel. Second-line maintenance addresses more complex problems requiring specialized skills or tools, typically performed by expert technicians or external service providers. Distinguishing between these levels enhances efficiency, reduces downtime, and extends the lifespan of assets.

Table of Comparison

| Aspect | First-Line Maintenance | Second-Line Maintenance |

|---|---|---|

| Definition | Routine tasks performed by operators or users on equipment. | Specialized repairs and diagnostics by skilled technicians. |

| Scope | Basic cleaning, lubrication, and minor adjustments. | Complex troubleshooting, part replacements, and overhauls. |

| Personnel | Operators, machine users. | Skilled maintenance technicians, engineers. |

| Tools & Equipment | Basic hand tools, standard checklists. | Specialized diagnostic and repair tools. |

| Frequency | Daily to weekly. | As needed based on failures or diagnostics. |

| Objective | Prevent minor issues and ensure operational performance. | Fix faults that exceed first-line capabilities. |

| Cost Implication | Lower cost, routine expenditure. | Higher cost due to specialized skills and tools. |

Introduction to Maintenance Levels

First-Line Maintenance involves routine tasks performed by equipment operators or on-site staff to ensure optimal operation and prevent minor breakdowns, emphasizing daily inspections, cleaning, and basic troubleshooting. Second-Line Maintenance requires specialized technicians or engineers to address more complex repairs, component replacements, and diagnostic activities beyond operator capabilities, ensuring sustained equipment reliability and extended asset lifespan. Understanding the distinction between these maintenance levels is crucial for effective asset management and minimizing operational downtime.

Defining First-Line Maintenance

First-line maintenance involves routine, basic tasks performed by machine operators or on-site staff, such as inspection, cleaning, lubrication, and minor adjustments to ensure equipment operates smoothly. This type of maintenance focuses on early detection and prevention of potential issues to minimize downtime and extend asset life. First-line maintenance acts as the initial layer of defense before escalating complex repairs or diagnostics to second-line maintenance specialists.

Key Responsibilities of First-Line Maintenance

First-line maintenance involves routine inspections, troubleshooting, and minor repairs performed directly by equipment operators or on-site technicians to ensure continuous operation and prevent downtime. Key responsibilities include identifying early signs of equipment failure, performing basic lubrication, cleaning, and adjustments, and documenting maintenance activities for further analysis. This immediate intervention reduces the need for specialized technical support from second-line maintenance teams, enhancing overall equipment efficiency.

Defining Second-Line Maintenance

Second-line maintenance involves more advanced repair tasks that require specialized skills, tools, and parts not typically available during first-line maintenance. This level addresses complex faults and component replacements to restore equipment functionality beyond routine inspections and minor fixes. Effective second-line maintenance reduces downtime by resolving issues that first-line maintenance cannot manage.

Key Responsibilities of Second-Line Maintenance

Second-line maintenance involves advanced technical support, including troubleshooting complex equipment failures and conducting in-depth diagnostics beyond the capabilities of first-line maintenance. It requires specialized skills to repair, calibrate, and restore machinery to operational status, often using sophisticated tools and software. This level also manages maintenance records, implements preventive measures, and supports first-line teams with technical guidance and training.

Core Differences Between First-Line and Second-Line Maintenance

First-line maintenance involves routine, on-the-spot tasks performed by equipment operators or frontline staff to ensure basic functionality and prevent minor issues. Second-line maintenance requires specialized technicians conducting more complex repairs, diagnostics, and component replacements beyond the capabilities of first-line personnel. The core difference lies in the skill level, complexity of tasks, and resources required, with first-line targeting immediate operational continuity and second-line addressing deeper technical problems.

Skills Required for First-Line Maintenance Technicians

First-Line Maintenance technicians require strong diagnostic skills, a solid understanding of mechanical and electrical systems, and proficiency in performing routine inspections and preventive maintenance tasks. They must be capable of identifying minor faults quickly, using basic tools and equipment, and executing immediate repairs to minimize equipment downtime. Effective communication skills are essential for reporting issues accurately and collaborating with Second-Line Maintenance teams when advanced technical expertise is necessary.

Skills Required for Second-Line Maintenance Technicians

Second-line maintenance technicians require advanced diagnostic skills and in-depth technical knowledge to troubleshoot complex equipment failures beyond basic repairs. Proficiency in reading detailed schematics, using specialized testing tools, and understanding system integration is essential for effective second-line maintenance. These technicians must also possess strong problem-solving abilities and the capacity to perform preventive and corrective maintenance on sophisticated machinery and control systems.

Impact on Operational Efficiency

First-line maintenance enhances operational efficiency by enabling quick identification and resolution of minor issues directly on the production floor, reducing equipment downtime and minimizing disruptions. Second-line maintenance involves more specialized repairs and preventive measures, ensuring long-term equipment reliability and preventing complex failures that could halt operations. Efficient coordination between first-line and second-line maintenance teams maximizes asset availability and supports continuous production workflows.

Choosing the Right Maintenance Strategy

First-Line Maintenance involves routine tasks such as inspections, cleaning, and basic repairs performed by operators to ensure equipment reliability and reduce downtime. Second-Line Maintenance requires specialized technicians for more complex repairs and preventive measures, addressing faults that exceed first-line capabilities. Selecting the right maintenance strategy depends on equipment criticality, resource availability, and cost-effectiveness to optimize operational efficiency and asset longevity.

First-Line Maintenance vs Second-Line Maintenance Infographic

jobdiv.com

jobdiv.com