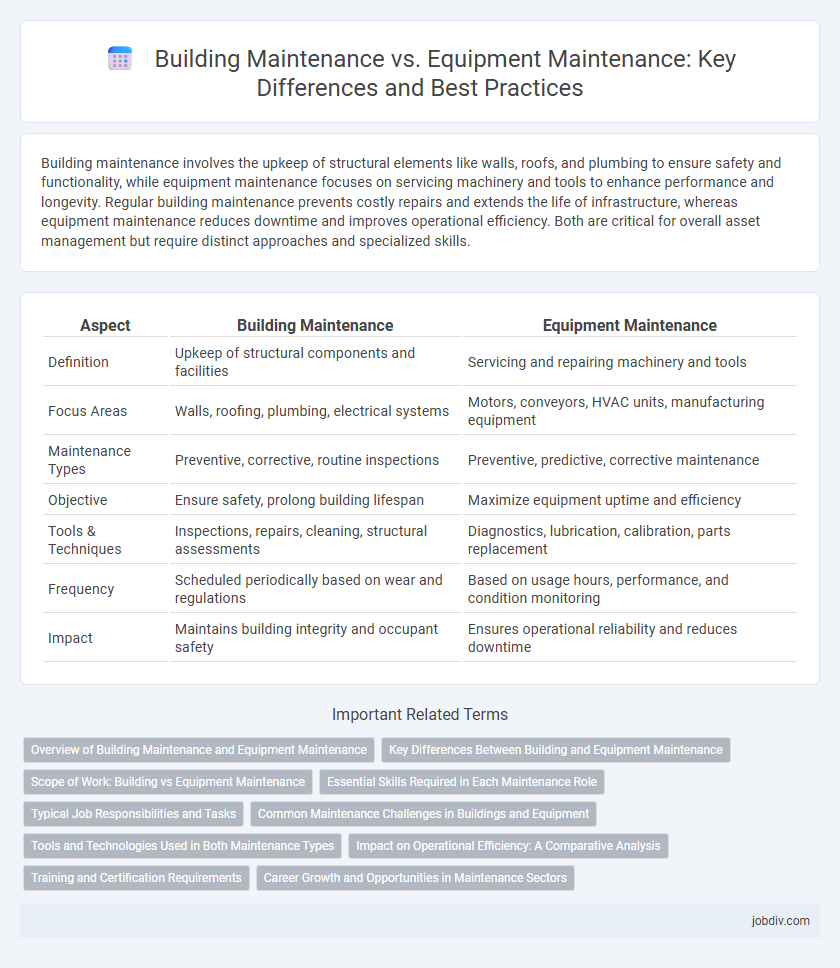

Building maintenance involves the upkeep of structural elements like walls, roofs, and plumbing to ensure safety and functionality, while equipment maintenance focuses on servicing machinery and tools to enhance performance and longevity. Regular building maintenance prevents costly repairs and extends the life of infrastructure, whereas equipment maintenance reduces downtime and improves operational efficiency. Both are critical for overall asset management but require distinct approaches and specialized skills.

Table of Comparison

| Aspect | Building Maintenance | Equipment Maintenance |

|---|---|---|

| Definition | Upkeep of structural components and facilities | Servicing and repairing machinery and tools |

| Focus Areas | Walls, roofing, plumbing, electrical systems | Motors, conveyors, HVAC units, manufacturing equipment |

| Maintenance Types | Preventive, corrective, routine inspections | Preventive, predictive, corrective maintenance |

| Objective | Ensure safety, prolong building lifespan | Maximize equipment uptime and efficiency |

| Tools & Techniques | Inspections, repairs, cleaning, structural assessments | Diagnostics, lubrication, calibration, parts replacement |

| Frequency | Scheduled periodically based on wear and regulations | Based on usage hours, performance, and condition monitoring |

| Impact | Maintains building integrity and occupant safety | Ensures operational reliability and reduces downtime |

Overview of Building Maintenance and Equipment Maintenance

Building maintenance involves routine inspections, repairs, and upkeep of structural elements such as walls, roofs, HVAC systems, plumbing, and electrical networks to ensure safety and functionality. Equipment maintenance focuses on the servicing, calibration, and repair of machinery and devices used in operations, aiming to maximize performance and minimize downtime. Both types of maintenance require systematic scheduling and skilled personnel to extend asset lifespan and optimize operational efficiency.

Key Differences Between Building and Equipment Maintenance

Building maintenance focuses on preserving the structural integrity, safety, and aesthetics of a facility by addressing tasks such as HVAC system upkeep, roofing repairs, and fire safety inspections. Equipment maintenance targets the functionality and performance of machinery through methods like preventive servicing, calibration, and lubrication to prevent breakdowns and extend operational lifespan. Key differences lie in the scope--building maintenance encompasses physical infrastructure and regulatory compliance, while equipment maintenance centers on mechanical efficiency and minimizing production downtime.

Scope of Work: Building vs Equipment Maintenance

Building maintenance encompasses the upkeep, repair, and preservation of structural elements such as walls, roofs, HVAC systems, plumbing, and electrical infrastructure, ensuring the safety and functionality of the entire facility. Equipment maintenance focuses exclusively on machinery and technical devices, involving tasks like lubrication, calibration, diagnostics, and component replacement to optimize operational efficiency and minimize downtime. The scope of work for building maintenance is broader and includes architectural and environmental factors, whereas equipment maintenance targets the mechanical and electronic integrity of individual assets.

Essential Skills Required in Each Maintenance Role

Building maintenance professionals must excel in skills such as structural inspection, plumbing, electrical systems troubleshooting, and HVAC system management to ensure safety and functionality. Equipment maintenance technicians require expertise in mechanical diagnostics, preventive maintenance, calibration, and repair of machinery to maximize operational efficiency and reduce downtime. Both roles demand strong problem-solving abilities, attention to detail, and proficiency in using maintenance management software for tracking and scheduling tasks.

Typical Job Responsibilities and Tasks

Building maintenance involves tasks such as inspecting structural components, repairing HVAC systems, managing electrical wiring, and ensuring compliance with safety regulations to maintain the overall integrity of the facility. Equipment maintenance focuses on routine servicing, troubleshooting mechanical or electronic malfunctions, calibrating machinery, and replacing worn parts to optimize performance and prevent downtime. Both disciplines require meticulous record-keeping and proactive scheduling to extend asset lifespan and ensure operational efficiency.

Common Maintenance Challenges in Buildings and Equipment

Building maintenance often faces challenges such as structural wear, HVAC system inefficiencies, and compliance with safety regulations, which can lead to increased operational costs if not addressed promptly. Equipment maintenance commonly struggles with unexpected breakdowns, parts availability, and improper usage, resulting in production downtime and higher repair expenses. Both domains require robust preventive maintenance schedules and skilled personnel to mitigate risks and extend asset lifespan effectively.

Tools and Technologies Used in Both Maintenance Types

Building maintenance utilizes advanced diagnostic tools such as thermal imaging cameras and moisture meters to detect structural issues and ensure safety compliance. Equipment maintenance employs predictive technologies including vibration analysis sensors and computerized maintenance management systems (CMMS) to monitor machine performance and schedule timely repairs. Both maintenance types increasingly integrate IoT devices and automation software to enhance efficiency and reduce downtime.

Impact on Operational Efficiency: A Comparative Analysis

Building maintenance ensures a safe, clean, and functional environment, directly reducing downtime caused by facility-related issues, while equipment maintenance targets the reliability and performance of machinery, preventing unexpected failures and costly repairs. Proactive equipment maintenance often yields higher operational efficiency by minimizing production interruptions, whereas building maintenance supports overall workplace productivity and employee well-being. Balancing both types of maintenance strategies is essential to optimize operational workflows and sustain long-term business performance.

Training and Certification Requirements

Building maintenance requires personnel to obtain certifications in safety regulations, HVAC systems, and electrical codes to ensure compliance and safe operation. Equipment maintenance demands specialized training on machinery diagnostics, preventive care, and technical repair skills certified by industry standards such as OSHA or manufacturer-specific programs. Both disciplines prioritize continuous education and certification renewal to adapt to evolving technologies and safety protocols.

Career Growth and Opportunities in Maintenance Sectors

Building maintenance offers diverse career paths including facility management, HVAC specialization, and safety compliance, with growth driven by urban expansion and sustainability trends. Equipment maintenance focuses on technical skills in machinery diagnostics, predictive maintenance, and automation, providing opportunities in manufacturing, energy, and transportation industries. Both sectors demand continuous upskilling and certification, enhancing long-term job security and advancement potential.

Building Maintenance vs Equipment Maintenance Infographic

jobdiv.com

jobdiv.com