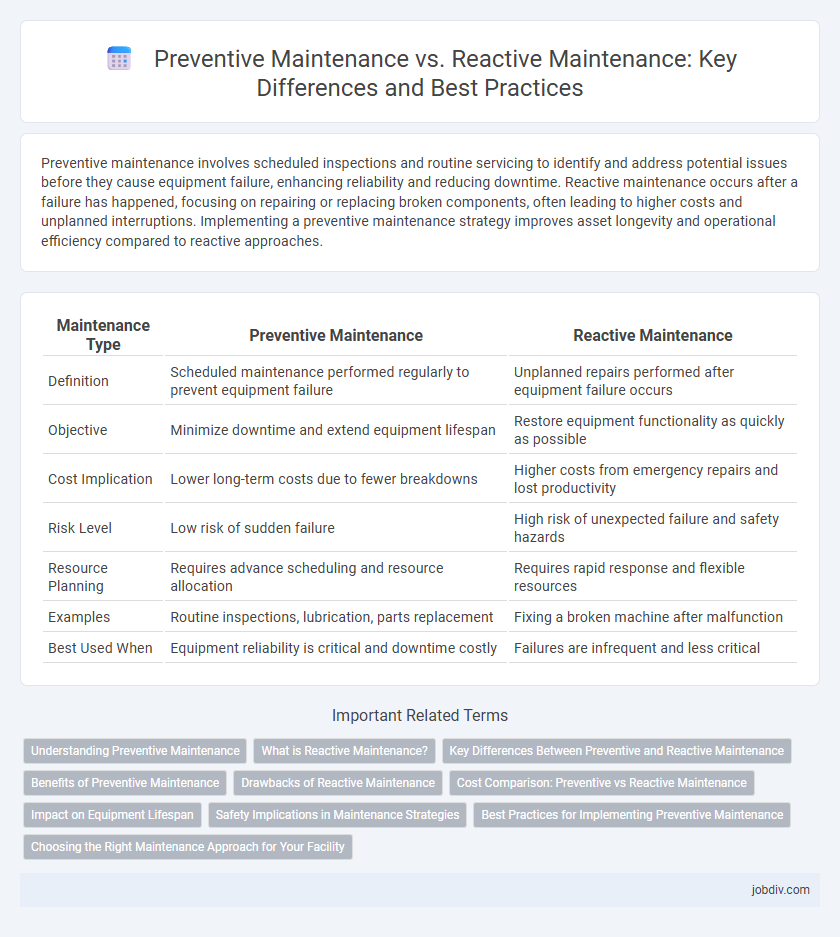

Preventive maintenance involves scheduled inspections and routine servicing to identify and address potential issues before they cause equipment failure, enhancing reliability and reducing downtime. Reactive maintenance occurs after a failure has happened, focusing on repairing or replacing broken components, often leading to higher costs and unplanned interruptions. Implementing a preventive maintenance strategy improves asset longevity and operational efficiency compared to reactive approaches.

Table of Comparison

| Maintenance Type | Preventive Maintenance | Reactive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance performed regularly to prevent equipment failure | Unplanned repairs performed after equipment failure occurs |

| Objective | Minimize downtime and extend equipment lifespan | Restore equipment functionality as quickly as possible |

| Cost Implication | Lower long-term costs due to fewer breakdowns | Higher costs from emergency repairs and lost productivity |

| Risk Level | Low risk of sudden failure | High risk of unexpected failure and safety hazards |

| Resource Planning | Requires advance scheduling and resource allocation | Requires rapid response and flexible resources |

| Examples | Routine inspections, lubrication, parts replacement | Fixing a broken machine after malfunction |

| Best Used When | Equipment reliability is critical and downtime costly | Failures are infrequent and less critical |

Understanding Preventive Maintenance

Preventive maintenance involves scheduled inspections and servicing of equipment to reduce the likelihood of unexpected failures, improving asset reliability and extending machinery lifespan. This approach uses data-driven strategies, including condition monitoring and predictive analytics, to anticipate and address issues before they cause downtime. Effective preventive maintenance lowers operational costs, enhances safety, and optimizes resource allocation compared to reactive maintenance, which focuses on repairing equipment after breakdowns occur.

What is Reactive Maintenance?

Reactive maintenance refers to the process of repairing equipment or machinery only after a failure or breakdown has occurred. This approach prioritizes immediate response to unexpected issues, often leading to increased downtime and higher repair costs. Organizations relying heavily on reactive maintenance may face reduced operational efficiency and shorter asset lifespans.

Key Differences Between Preventive and Reactive Maintenance

Preventive maintenance involves scheduled inspections and proactive repairs to avoid equipment failures, reducing downtime and extending asset life. Reactive maintenance occurs after equipment failure, often leading to higher repair costs, unexpected downtime, and potential safety risks. Key differences lie in timing, cost efficiency, and impact on operational reliability, with preventive maintenance focusing on long-term asset health and reactive maintenance addressing immediate breakdowns.

Benefits of Preventive Maintenance

Preventive maintenance significantly reduces equipment downtime by addressing potential issues before they escalate into major failures, ensuring higher operational reliability. It extends asset lifespan through scheduled inspections and timely replacements, minimizing costly emergency repairs frequently associated with reactive maintenance. Organizations implementing preventive maintenance protocols experience enhanced safety standards and improved production efficiency, resulting in lower overall maintenance costs.

Drawbacks of Reactive Maintenance

Reactive maintenance often leads to higher repair costs due to unexpected equipment failures and extended downtime. It increases the risk of catastrophic breakdowns, impacting overall operational efficiency and safety. Reliance on reactive maintenance can also result in shortened asset lifespan and unpredictable maintenance scheduling.

Cost Comparison: Preventive vs Reactive Maintenance

Preventive maintenance reduces long-term costs by addressing equipment issues before failure, minimizing expensive downtime and costly emergency repairs. Reactive maintenance often leads to higher expenses due to unexpected breakdowns, extended production halts, and accelerated asset wear. Companies experience up to 30% lower maintenance costs with preventive strategies compared to reactive approaches.

Impact on Equipment Lifespan

Preventive maintenance significantly extends equipment lifespan by addressing wear and potential failures before they occur, reducing downtime and costly repairs. Reactive maintenance often leads to accelerated equipment degradation due to unresolved issues causing increased stress and breakdowns. Implementing preventive strategies enhances operational efficiency and maximizes asset longevity in industrial and manufacturing settings.

Safety Implications in Maintenance Strategies

Preventive maintenance reduces safety risks by ensuring equipment reliability and early detection of potential hazards, minimizing unexpected failures. Reactive maintenance often increases safety hazards due to unplanned downtime and breakdowns, exposing workers to dangerous emergency repairs. Implementing a preventive approach enhances workplace safety and compliance with safety regulations, reducing accident rates and injury incidents.

Best Practices for Implementing Preventive Maintenance

Implementing preventive maintenance requires establishing a detailed schedule based on equipment manufacturer guidelines and historical performance data to minimize unexpected failures. Utilizing Computerized Maintenance Management Systems (CMMS) enhances tracking, alerts, and documentation efficiency, ensuring consistent execution of maintenance tasks. Training maintenance personnel on predictive techniques and proper inspection protocols improves reliability and extends asset lifespan compared to reactive maintenance approaches.

Choosing the Right Maintenance Approach for Your Facility

Choosing the right maintenance approach for your facility hinges on balancing cost-efficiency and operational reliability. Preventive maintenance involves scheduled inspections and routine repairs that minimize unexpected equipment failures, enhancing uptime and extending asset lifespan. Reactive maintenance, while less resource-intensive upfront, risks higher long-term expenses and downtime due to unplanned breakdowns, making it best suited for non-critical equipment or facilities with limited maintenance budgets.

Preventive Maintenance vs Reactive Maintenance Infographic

jobdiv.com

jobdiv.com