Site maintenance involves performing repairs and upkeep tasks at a fixed location, ensuring equipment and infrastructure operate efficiently within a controlled environment. Field maintenance refers to servicing machinery and assets on-site at various operational locations, often requiring mobile resources and adaptability to diverse conditions. Comparing both, site maintenance offers a stable setting for routine checks, while field maintenance demands flexibility to manage unexpected breakdowns and remote repairs.

Table of Comparison

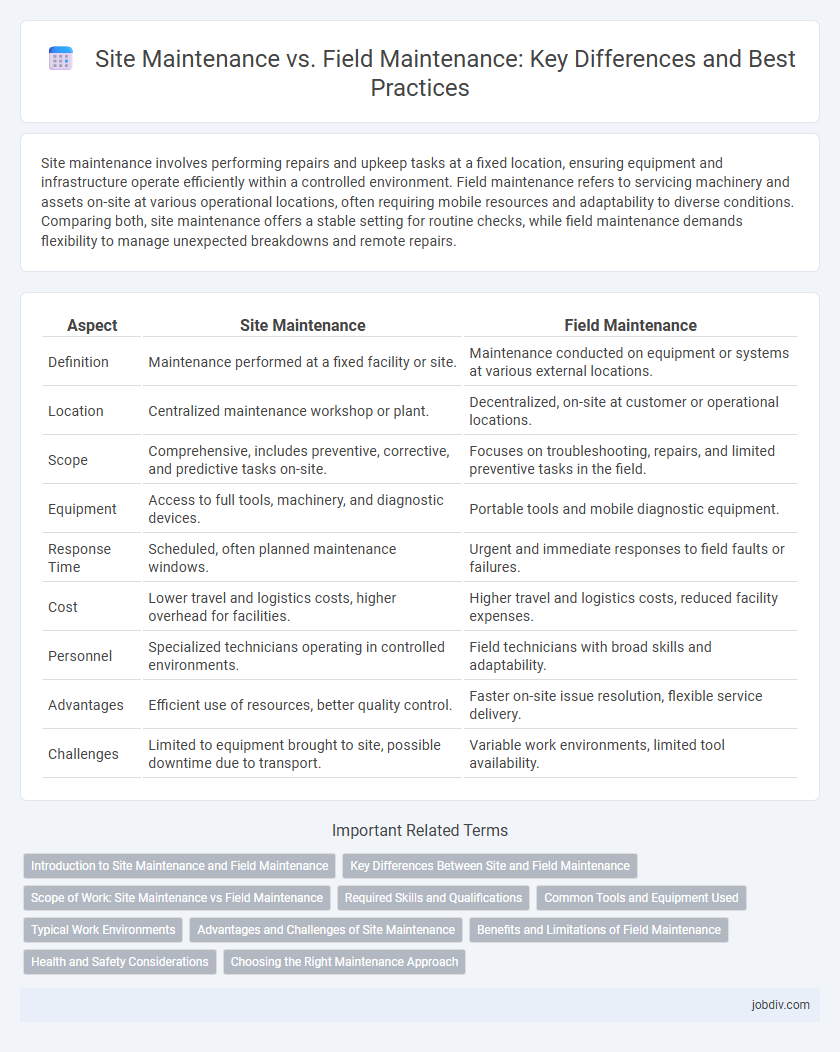

| Aspect | Site Maintenance | Field Maintenance |

|---|---|---|

| Definition | Maintenance performed at a fixed facility or site. | Maintenance conducted on equipment or systems at various external locations. |

| Location | Centralized maintenance workshop or plant. | Decentralized, on-site at customer or operational locations. |

| Scope | Comprehensive, includes preventive, corrective, and predictive tasks on-site. | Focuses on troubleshooting, repairs, and limited preventive tasks in the field. |

| Equipment | Access to full tools, machinery, and diagnostic devices. | Portable tools and mobile diagnostic equipment. |

| Response Time | Scheduled, often planned maintenance windows. | Urgent and immediate responses to field faults or failures. |

| Cost | Lower travel and logistics costs, higher overhead for facilities. | Higher travel and logistics costs, reduced facility expenses. |

| Personnel | Specialized technicians operating in controlled environments. | Field technicians with broad skills and adaptability. |

| Advantages | Efficient use of resources, better quality control. | Faster on-site issue resolution, flexible service delivery. |

| Challenges | Limited to equipment brought to site, possible downtime due to transport. | Variable work environments, limited tool availability. |

Introduction to Site Maintenance and Field Maintenance

Site maintenance involves routine inspections and repairs conducted at a fixed location, ensuring optimal operation of equipment and infrastructure within a facility. Field maintenance refers to on-site servicing performed at various external locations, often addressing urgent or unexpected issues in real-time. Both maintenance types are crucial for minimizing downtime and extending asset lifespan in industrial and service environments.

Key Differences Between Site and Field Maintenance

Site maintenance involves upkeep and repairs performed directly at a fixed location like a facility or plant, focusing on infrastructure, machinery, and systems in a controlled environment. Field maintenance occurs off-site, often in diverse or remote locations, dealing with equipment and assets deployed in operational settings, emphasizing mobility and adaptability. Key differences include work environment, resource availability, and the nature of tasks, with site maintenance benefiting from fixed tools and facilities, while field maintenance requires portable equipment and quick problem-solving skills.

Scope of Work: Site Maintenance vs Field Maintenance

Site maintenance primarily involves routine inspections, repairs, and preventive measures conducted within a fixed location, such as a manufacturing plant or office building, focusing on infrastructure, equipment, and systems onsite. Field maintenance covers a broader range of tasks performed offsite, including troubleshooting, repairs, and installations directly at customer locations or remote facilities, often requiring mobility and adaptability. The scope of work in site maintenance is generally controlled and repetitive, whereas field maintenance demands versatile technical skills to address diverse environmental conditions and equipment types.

Required Skills and Qualifications

Site maintenance requires technical skills in equipment troubleshooting, preventive maintenance procedures, and familiarity with safety regulations specific to the facility. Field maintenance demands versatility, strong diagnostic abilities, and proficiency in mobile repair tools to address issues on varied equipment across multiple locations. Both roles require certifications such as OSHA compliance and technical training, but field maintenance often necessitates broader adaptability and excellent problem-solving skills in unpredictable environments.

Common Tools and Equipment Used

Site maintenance and field maintenance both rely on essential tools and equipment to ensure operational efficiency and safety. Common tools used include handheld instruments such as multimeters, wrenches, screwdrivers, torque tools, and diagnostic devices tailored for electrical, mechanical, and plumbing tasks. Field maintenance often emphasizes portable and rugged tools like battery-powered drills, mobile testing equipment, and safety gear to facilitate on-site repairs and inspections in diverse environments.

Typical Work Environments

Site maintenance typically occurs in controlled environments like factories, commercial buildings, or data centers, where equipment is stationary and infrastructure is fixed. Field maintenance involves working in dynamic, outdoor, or remote locations such as utility lines, construction sites, and transportation networks, requiring technicians to adapt to varying conditions. Understanding these environments helps optimize resource allocation and training for maintenance teams.

Advantages and Challenges of Site Maintenance

Site Maintenance offers advantages such as immediate access to specialized tools and equipment, ensuring comprehensive inspections and repairs, which can improve overall system reliability and reduce downtime. Challenges include the need for on-site skilled personnel and potential safety risks due to environmental factors, which may increase operational costs and complicate scheduling. Effective planning and resource allocation are essential to maximize the benefits and mitigate the difficulties associated with Site Maintenance.

Benefits and Limitations of Field Maintenance

Field maintenance offers the benefit of immediate response and real-time troubleshooting at the equipment location, reducing downtime and minimizing transportation costs. Limitations include dependency on site accessibility, potential safety risks in hazardous environments, and the need for highly skilled technicians equipped with portable tools. Its effectiveness is often constrained by the complexity of repairs that can be performed remotely compared to comprehensive site maintenance.

Health and Safety Considerations

Site maintenance involves routine inspections and repairs conducted in controlled environments, reducing exposure to hazardous conditions and enabling comprehensive safety protocols. Field maintenance requires technicians to perform repairs in unpredictable and often challenging environments, emphasizing the need for portable safety equipment, risk assessments, and emergency preparedness. Prioritizing health and safety in both settings minimizes incidents and ensures compliance with occupational safety regulations.

Choosing the Right Maintenance Approach

Site maintenance optimizes resources by addressing equipment repairs and inspections within a controlled environment, reducing downtime and improving safety. Field maintenance, essential for remote or on-site machinery, ensures timely interventions, minimizing operational disruptions and transportation costs. Selecting the right maintenance approach depends on equipment location, criticality, and available technical expertise to balance efficiency and cost-effectiveness.

Site Maintenance vs Field Maintenance Infographic

jobdiv.com

jobdiv.com