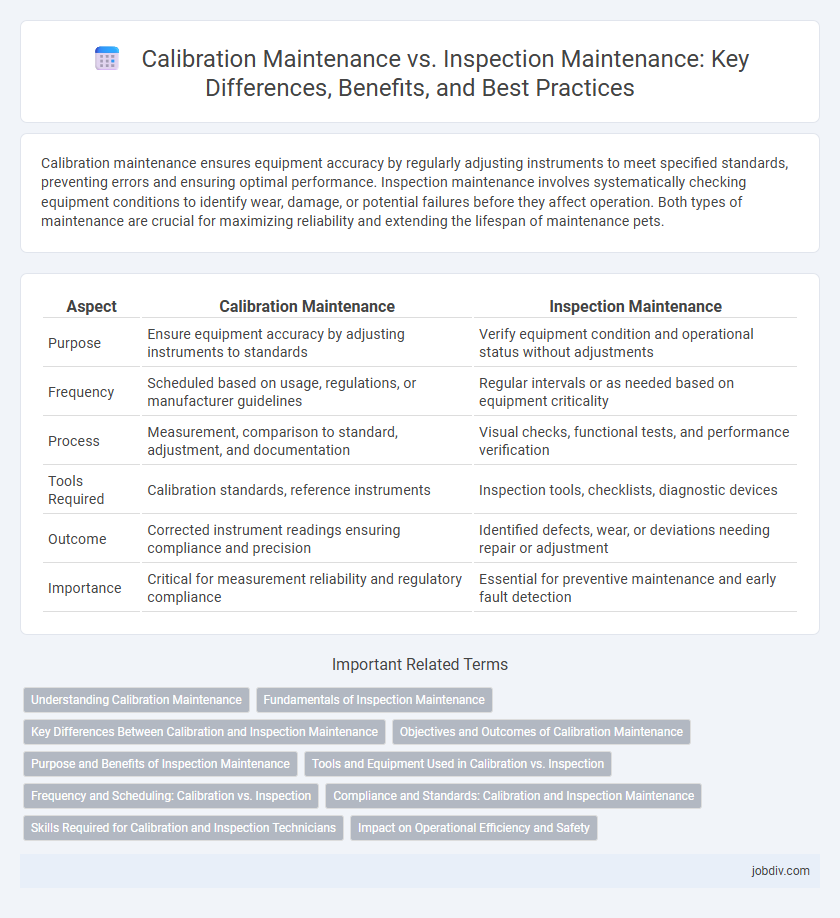

Calibration maintenance ensures equipment accuracy by regularly adjusting instruments to meet specified standards, preventing errors and ensuring optimal performance. Inspection maintenance involves systematically checking equipment conditions to identify wear, damage, or potential failures before they affect operation. Both types of maintenance are crucial for maximizing reliability and extending the lifespan of maintenance pets.

Table of Comparison

| Aspect | Calibration Maintenance | Inspection Maintenance |

|---|---|---|

| Purpose | Ensure equipment accuracy by adjusting instruments to standards | Verify equipment condition and operational status without adjustments |

| Frequency | Scheduled based on usage, regulations, or manufacturer guidelines | Regular intervals or as needed based on equipment criticality |

| Process | Measurement, comparison to standard, adjustment, and documentation | Visual checks, functional tests, and performance verification |

| Tools Required | Calibration standards, reference instruments | Inspection tools, checklists, diagnostic devices |

| Outcome | Corrected instrument readings ensuring compliance and precision | Identified defects, wear, or deviations needing repair or adjustment |

| Importance | Critical for measurement reliability and regulatory compliance | Essential for preventive maintenance and early fault detection |

Understanding Calibration Maintenance

Calibration maintenance ensures precision by systematically adjusting instruments to meet standardized measurements, reducing errors and enhancing equipment reliability. It involves detailed procedures using reference standards to verify and correct measurement accuracy, essential for high-quality production and regulatory compliance. Unlike inspection maintenance, which primarily identifies faults, calibration maintenance actively corrects instrument deviations to maintain optimal performance.

Fundamentals of Inspection Maintenance

Inspection maintenance involves regularly scheduled checks to assess equipment condition, identify potential issues, and ensure operational safety without making adjustments or repairs. It focuses on detecting wear, leaks, or abnormalities through visual, auditory, or measurement techniques, serving as a preventive step before calibration or corrective maintenance. Calibration maintenance, in contrast, specifically adjusts and fine-tunes instruments to maintain accuracy and performance according to defined standards.

Key Differences Between Calibration and Inspection Maintenance

Calibration maintenance involves adjusting instruments to ensure measurement accuracy against a known standard, directly impacting operational precision and product quality. Inspection maintenance focuses on the visual or instrumental examination of equipment to detect wear, defects, or deviations without altering the device's settings. The key difference lies in calibration's role in correcting measurement errors versus inspection's purpose of identifying potential issues for preventive action.

Objectives and Outcomes of Calibration Maintenance

Calibration maintenance ensures that equipment operates within specified tolerances by adjusting instruments to meet accuracy standards, which improves measurement reliability and process consistency. Its primary objective is to minimize measurement errors and maintain compliance with industry regulations, thereby reducing downtime and costly rework. Inspection maintenance, in contrast, aims to detect wear or damage early through regular checks without necessarily adjusting equipment parameters.

Purpose and Benefits of Inspection Maintenance

Inspection maintenance focuses on identifying wear, damage, or potential failures through regular visual and functional checks, ensuring equipment reliability and safety. Its purpose includes early detection of issues to prevent unexpected breakdowns and extend asset lifespan. Benefits include reduced downtime, enhanced operational efficiency, and cost savings by addressing problems before they escalate.

Tools and Equipment Used in Calibration vs. Inspection

Calibration maintenance utilizes specialized instruments such as calibrators, micrometers, and signal generators to ensure measurement accuracy and compliance with standards. Inspection maintenance relies on visual aids, gauges, and non-destructive testing tools like ultrasonic or magnetic particle testers to detect wear, defects, and operational integrity. The choice of tools directly impacts the effectiveness of each maintenance type, with calibration focusing on precision measurement and inspection emphasizing condition assessment.

Frequency and Scheduling: Calibration vs. Inspection

Calibration maintenance requires scheduling based on manufacturer specifications or industry standards, often at fixed intervals to ensure measurement accuracy and instrument reliability. Inspection maintenance follows a more flexible frequency, typically performed more frequently or condition-based to identify wear, damage, or potential failures. Proper scheduling of both calibration and inspection maintenance ensures optimal equipment performance and compliance with quality standards.

Compliance and Standards: Calibration and Inspection Maintenance

Calibration maintenance ensures that measurement instruments meet stringent compliance and industry standards by adjusting devices to deliver accurate readings, crucial for regulatory adherence and quality control. Inspection maintenance focuses on evaluating equipment conditions without adjustments, identifying potential issues to maintain operational standards and prevent non-compliance. Both practices are essential for maintaining certification requirements and guaranteeing product safety and reliability.

Skills Required for Calibration and Inspection Technicians

Calibration maintenance technicians require advanced skills in precision measurement, the use of specialized calibration equipment, and a deep understanding of instrument tolerances and standards. Inspection maintenance technicians need strong observational skills, proficiency in visual and functional testing, and knowledge of safety regulations and operational protocols to identify potential defects. Both roles demand technical expertise, but calibration emphasizes accuracy and traceability, whereas inspection focuses on condition assessment and compliance verification.

Impact on Operational Efficiency and Safety

Calibration maintenance involves precise adjustment of instruments to ensure measurement accuracy, directly enhancing operational efficiency by minimizing errors and downtime. Inspection maintenance focuses on identifying wear and potential failures early, which significantly improves safety by preventing accidents and equipment malfunctions. Integrating both maintenance types optimizes overall system reliability, reduces unexpected breakdowns, and maintains compliance with safety standards.

Calibration Maintenance vs Inspection Maintenance Infographic

jobdiv.com

jobdiv.com