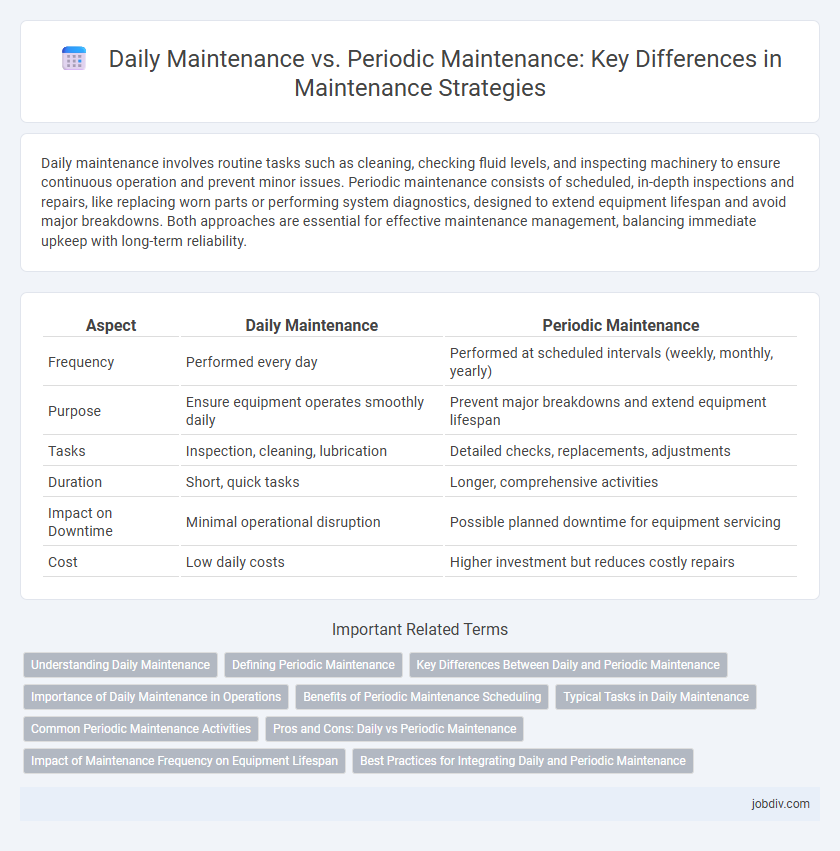

Daily maintenance involves routine tasks such as cleaning, checking fluid levels, and inspecting machinery to ensure continuous operation and prevent minor issues. Periodic maintenance consists of scheduled, in-depth inspections and repairs, like replacing worn parts or performing system diagnostics, designed to extend equipment lifespan and avoid major breakdowns. Both approaches are essential for effective maintenance management, balancing immediate upkeep with long-term reliability.

Table of Comparison

| Aspect | Daily Maintenance | Periodic Maintenance |

|---|---|---|

| Frequency | Performed every day | Performed at scheduled intervals (weekly, monthly, yearly) |

| Purpose | Ensure equipment operates smoothly daily | Prevent major breakdowns and extend equipment lifespan |

| Tasks | Inspection, cleaning, lubrication | Detailed checks, replacements, adjustments |

| Duration | Short, quick tasks | Longer, comprehensive activities |

| Impact on Downtime | Minimal operational disruption | Possible planned downtime for equipment servicing |

| Cost | Low daily costs | Higher investment but reduces costly repairs |

Understanding Daily Maintenance

Daily maintenance involves routine tasks performed every day to ensure optimal operation and promptly detect potential issues in equipment or systems. It includes inspecting, cleaning, lubrication, and basic adjustments that prevent breakdowns and extend asset lifespan. Understanding daily maintenance is essential for minimizing downtime and maintaining continuous productivity in industrial and facility management.

Defining Periodic Maintenance

Periodic maintenance involves scheduled inspections and servicing tasks performed at predetermined intervals based on time, usage, or operational conditions to prevent equipment failure and extend asset lifespan. Unlike daily maintenance, which addresses immediate and routine operational needs, periodic maintenance is designed to detect potential issues before they escalate into costly repairs. This proactive approach includes activities such as lubrication, calibration, component replacement, and system testing, optimizing overall reliability and performance.

Key Differences Between Daily and Periodic Maintenance

Daily maintenance involves routine tasks performed every day to ensure equipment runs smoothly and prevent minor issues from escalating. Periodic maintenance occurs at scheduled intervals, such as weekly or monthly, focusing on more detailed inspections and repairs to maintain long-term reliability. Key differences include frequency, scope, and the depth of activities, with daily maintenance emphasizing immediate operational stability and periodic maintenance targeting comprehensive system upkeep.

Importance of Daily Maintenance in Operations

Daily maintenance is crucial for ensuring continuous operation and preventing unexpected equipment failures by addressing minor issues before they escalate. Regular daily checks improve reliability, extend the lifespan of machinery, and reduce costly downtime in production environments. Consistent attention through daily maintenance fosters a safer workplace and optimizes overall operational efficiency.

Benefits of Periodic Maintenance Scheduling

Periodic maintenance scheduling enhances equipment reliability by systematically addressing wear and tear before failures occur, reducing unexpected downtime and costly repairs. This proactive approach optimizes resource allocation and extends the lifespan of machinery through timely inspections and part replacements. Compared to daily maintenance, periodic schedules ensure comprehensive upkeep aligned with manufacturer guidelines and operational demands, boosting overall productivity and safety.

Typical Tasks in Daily Maintenance

Typical tasks in daily maintenance include equipment inspection, cleaning, lubrication, and basic adjustments to ensure optimal performance and prevent unexpected breakdowns. These routine activities help identify minor issues early, reducing downtime and extending machinery lifespan. Regularly monitoring operational parameters and recording observations support timely corrective actions and enhance overall maintenance efficiency.

Common Periodic Maintenance Activities

Common periodic maintenance activities include inspecting and lubricating machinery, replacing worn-out parts, and calibrating equipment to ensure optimal performance. These tasks are performed at scheduled intervals, such as monthly or quarterly, to prevent unexpected breakdowns and extend asset lifespan. Regular cleaning, tightening of bolts, and checking fluid levels are also essential components of effective periodic maintenance programs.

Pros and Cons: Daily vs Periodic Maintenance

Daily maintenance ensures consistent equipment performance and immediate issue detection, minimizing unexpected downtime but can increase labor costs and may lead to unnecessary inspections. Periodic maintenance reduces routine labor expenses by scheduling tasks at longer intervals, which can optimize resource allocation but risks overlooking early signs of equipment failure. Balancing daily and periodic maintenance strategies enhances asset longevity by aligning inspection frequencies with operational demands and equipment criticality.

Impact of Maintenance Frequency on Equipment Lifespan

Daily maintenance tasks such as cleaning, lubrication, and inspection help prevent minor breakdowns and reduce wear, thereby extending equipment lifespan by maintaining optimal operating conditions. Periodic maintenance, performed at scheduled intervals based on usage hours or calendar time, addresses more significant repairs and component replacements that daily checks might miss, ensuring long-term reliability and preventing sudden failures. Balancing daily and periodic maintenance optimizes equipment availability and minimizes downtime, ultimately maximizing the asset's useful life and reducing total lifecycle costs.

Best Practices for Integrating Daily and Periodic Maintenance

Integrating daily and periodic maintenance enhances equipment reliability by ensuring minor issues are addressed promptly while comprehensive inspections prevent long-term failures. Best practices involve scheduling daily tasks focused on cleaning, lubrication, and visual checks, complemented by detailed periodic assessments like calibrations and component replacements. Utilizing computerized maintenance management systems (CMMS) allows for seamless coordination between daily and periodic activities, optimizing resource allocation and minimizing downtime.

Daily Maintenance vs Periodic Maintenance Infographic

jobdiv.com

jobdiv.com