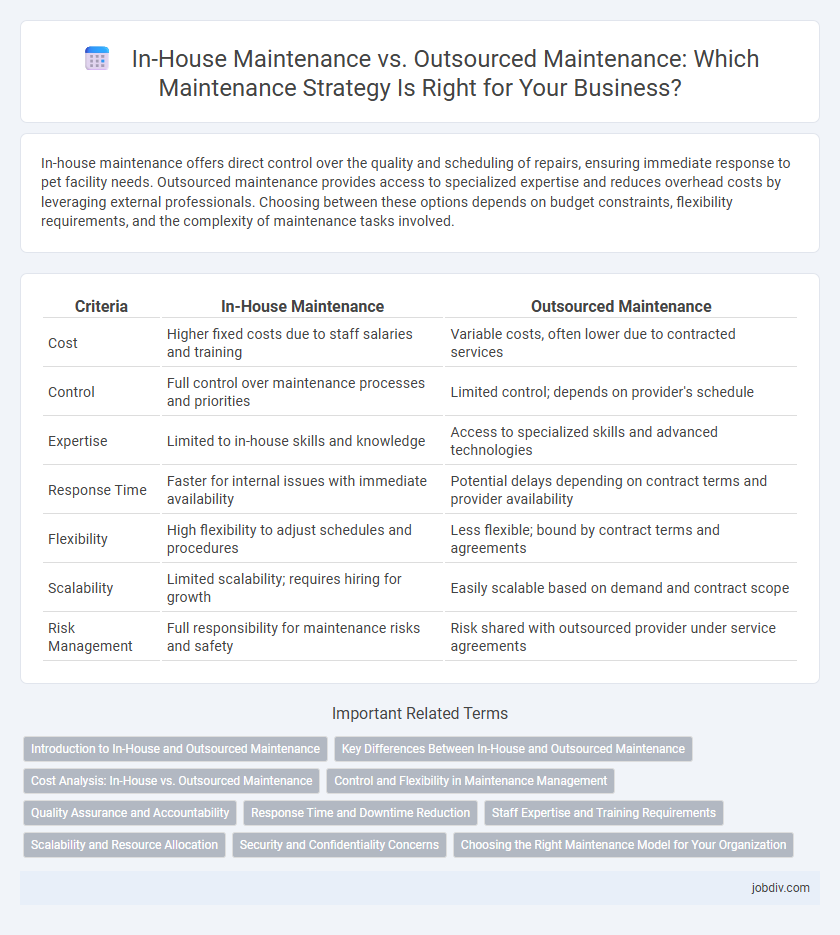

In-house maintenance offers direct control over the quality and scheduling of repairs, ensuring immediate response to pet facility needs. Outsourced maintenance provides access to specialized expertise and reduces overhead costs by leveraging external professionals. Choosing between these options depends on budget constraints, flexibility requirements, and the complexity of maintenance tasks involved.

Table of Comparison

| Criteria | In-House Maintenance | Outsourced Maintenance |

|---|---|---|

| Cost | Higher fixed costs due to staff salaries and training | Variable costs, often lower due to contracted services |

| Control | Full control over maintenance processes and priorities | Limited control; depends on provider's schedule |

| Expertise | Limited to in-house skills and knowledge | Access to specialized skills and advanced technologies |

| Response Time | Faster for internal issues with immediate availability | Potential delays depending on contract terms and provider availability |

| Flexibility | High flexibility to adjust schedules and procedures | Less flexible; bound by contract terms and agreements |

| Scalability | Limited scalability; requires hiring for growth | Easily scalable based on demand and contract scope |

| Risk Management | Full responsibility for maintenance risks and safety | Risk shared with outsourced provider under service agreements |

Introduction to In-House and Outsourced Maintenance

In-house maintenance involves employing skilled technicians within the organization to handle equipment repairs and routine upkeep, allowing for direct control and immediate response to issues. Outsourced maintenance contracts external service providers with specialized expertise and resources to manage maintenance tasks, often reducing labor costs and providing access to advanced technology. Choosing between in-house and outsourced maintenance depends on factors such as cost efficiency, complexity of equipment, and the need for specialized skills.

Key Differences Between In-House and Outsourced Maintenance

In-house maintenance involves employing dedicated staff who possess intimate knowledge of company equipment and processes, allowing for rapid response and tailored solutions, while outsourced maintenance leverages specialized external providers offering scalability and access to advanced technologies. Cost structures diverge; in-house maintenance often requires significant upfront investment in training and tools, whereas outsourcing shifts expenses to a variable cost model based on service contracts. Reliability and control also differ, with in-house teams providing direct oversight and immediate intervention capabilities, contrasted with outsourced services that may introduce communication delays but deliver expertise across multiple industries.

Cost Analysis: In-House vs. Outsourced Maintenance

In-house maintenance involves fixed costs such as salaries, training, equipment, and facility expenses, which can lead to higher upfront investments but greater control over quality and response times. Outsourced maintenance typically converts fixed costs into variable costs, providing flexibility and potential savings through specialized expertise and economies of scale. A comprehensive cost analysis should factor in direct expenses, downtime costs, and potential efficiency gains to determine the optimal maintenance strategy for an organization.

Control and Flexibility in Maintenance Management

In-house maintenance offers greater control and flexibility by allowing direct oversight of scheduling, resource allocation, and immediate response to equipment issues. Outsourced maintenance can limit control but provides specialized expertise and scalability, which may improve efficiency for complex systems. Balancing control and flexibility is critical for optimizing maintenance management strategies based on organizational needs and operational priorities.

Quality Assurance and Accountability

In-house maintenance teams provide direct oversight, ensuring quality assurance through consistent monitoring and immediate accountability for service standards. Outsourced maintenance relies on third-party vendors, which can introduce variability in quality and complicate accountability due to contract dependencies and communication gaps. Companies often prefer in-house maintenance to maintain stringent quality control and clear responsibility pathways for equipment performance and safety compliance.

Response Time and Downtime Reduction

In-house maintenance teams offer faster response times due to immediate on-site availability, significantly reducing equipment downtime. Outsourced maintenance may have longer response times as technicians travel to the site, potentially increasing downtime. Leveraging in-house maintenance ensures quicker troubleshooting and repairs, optimizing operational continuity.

Staff Expertise and Training Requirements

In-house maintenance demands a workforce with specialized expertise and continuous training to handle complex machinery and swiftly resolve technical issues, ensuring operational efficiency. Outsourced maintenance providers typically bring highly trained professionals with broad industry experience, reducing the burden of ongoing staff training for the company. Evaluating the cost and depth of expertise required helps determine whether internal skill development or external specialist engagement best supports maintenance goals.

Scalability and Resource Allocation

In-house maintenance offers greater control over resource allocation, enabling tailored workforce scaling according to operational demands. Outsourced maintenance provides scalability advantages by leveraging external expertise and flexible service contracts, reducing the need for permanent staff and capital investment. Strategic decision-making balances in-house capabilities with outsourced options to optimize resource utilization and meet fluctuating maintenance requirements efficiently.

Security and Confidentiality Concerns

In-house maintenance offers greater control over security protocols and confidentiality by limiting access to sensitive information within the organization, reducing the risk of data breaches. Outsourced maintenance can expose proprietary systems to external vendors, increasing potential vulnerabilities and requiring rigorous contractual safeguards and monitoring. Organizations must weigh the balance between convenience and the imperative to protect intellectual property and confidential data when deciding between these maintenance approaches.

Choosing the Right Maintenance Model for Your Organization

Selecting the appropriate maintenance model depends on your organization's size, budget, and core competencies. In-house maintenance offers direct control and faster response times, ideal for businesses with specialized equipment and skilled technicians. Outsourced maintenance provides cost savings and access to expert resources, benefiting companies aiming to reduce operational overhead while ensuring high service quality.

In-House Maintenance vs Outsourced Maintenance Infographic

jobdiv.com

jobdiv.com