Routine maintenance ensures the ongoing health and comfort of pets through scheduled check-ups, grooming, and feeding, preventing potential health issues before they escalate. Emergency maintenance addresses unexpected problems such as sudden injuries or illnesses requiring immediate veterinary attention to avoid serious complications. Prioritizing routine care reduces the frequency and severity of emergencies, promoting a safer, healthier environment for pets.

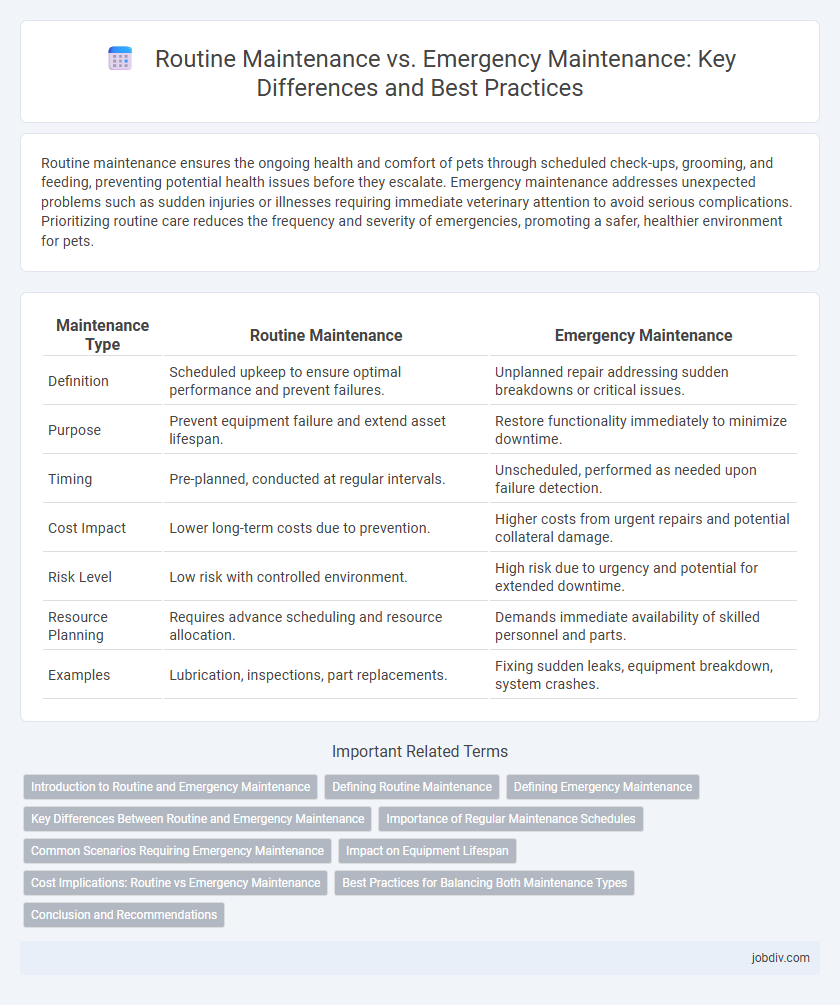

Table of Comparison

| Maintenance Type | Routine Maintenance | Emergency Maintenance |

|---|---|---|

| Definition | Scheduled upkeep to ensure optimal performance and prevent failures. | Unplanned repair addressing sudden breakdowns or critical issues. |

| Purpose | Prevent equipment failure and extend asset lifespan. | Restore functionality immediately to minimize downtime. |

| Timing | Pre-planned, conducted at regular intervals. | Unscheduled, performed as needed upon failure detection. |

| Cost Impact | Lower long-term costs due to prevention. | Higher costs from urgent repairs and potential collateral damage. |

| Risk Level | Low risk with controlled environment. | High risk due to urgency and potential for extended downtime. |

| Resource Planning | Requires advance scheduling and resource allocation. | Demands immediate availability of skilled personnel and parts. |

| Examples | Lubrication, inspections, part replacements. | Fixing sudden leaks, equipment breakdown, system crashes. |

Introduction to Routine and Emergency Maintenance

Routine maintenance involves scheduled inspections and preventive tasks designed to ensure equipment operates efficiently and to minimize unexpected breakdowns. Emergency maintenance occurs in response to sudden equipment failures or critical malfunctions requiring immediate repairs to restore functionality and prevent further damage. Understanding the distinction between these maintenance types helps organizations optimize resource allocation and reduce downtime.

Defining Routine Maintenance

Routine maintenance involves scheduled inspections and servicing tasks designed to prevent equipment failures and extend asset lifespan. It includes activities such as lubrication, cleaning, adjustments, and part replacements performed according to a predetermined plan. This proactive approach minimizes unexpected downtime and ensures consistent operational efficiency.

Defining Emergency Maintenance

Emergency maintenance refers to urgent repair activities required to address sudden equipment failures or safety hazards that disrupt normal operations. This type of maintenance demands immediate attention to prevent extensive damage, minimize downtime, and ensure workplace safety. Unlike routine maintenance, emergency maintenance occurs unpredictably and prioritizes rapid response and resolution.

Key Differences Between Routine and Emergency Maintenance

Routine maintenance involves scheduled inspections and minor repairs aimed at preventing equipment failure, ensuring consistent operational efficiency and reducing downtime. Emergency maintenance occurs unexpectedly, addressing critical breakdowns or safety hazards that require immediate attention to restore functionality and minimize damage. Key differences include planning, with routine maintenance being proactive and planned, whereas emergency maintenance is reactive and unpredictable, often incurring higher costs and operational disruption.

Importance of Regular Maintenance Schedules

Regular maintenance schedules are crucial for preventing unexpected breakdowns and extending the lifespan of equipment. Routine maintenance identifies potential issues early, reducing costly emergency repairs and downtime. Consistently following these schedules ensures operational efficiency and enhances safety in industrial and commercial settings.

Common Scenarios Requiring Emergency Maintenance

Common scenarios requiring emergency maintenance include sudden equipment failures, critical system breakdowns, and unexpected safety hazards that disrupt operations. These incidents demand immediate attention to prevent extensive damage, minimize downtime, and ensure workplace safety. Routine maintenance, by contrast, focuses on scheduled inspections and preventive measures to reduce the likelihood of emergencies.

Impact on Equipment Lifespan

Routine maintenance enhances equipment lifespan by preventing wear and addressing minor issues before they escalate into major failures. Emergency maintenance often results from unexpected breakdowns, leading to increased stress on components and a higher risk of long-term damage. Consistent, scheduled upkeep optimizes operational efficiency and reduces the total cost of ownership by minimizing unplanned downtime.

Cost Implications: Routine vs Emergency Maintenance

Routine maintenance typically incurs lower costs by preventing major equipment failures and extending asset lifespan through scheduled inspections and minor repairs. Emergency maintenance often results in significantly higher expenses due to urgent repair needs, unplanned downtime, and potential collateral damage. Effective routine maintenance strategies reduce the frequency and severity of costly emergency interventions, optimizing overall operational budgets.

Best Practices for Balancing Both Maintenance Types

Effective balance between routine maintenance and emergency maintenance relies on a structured schedule incorporating predictive analytics and condition monitoring to reduce unexpected failures. Implementing comprehensive asset management systems enhances visibility into equipment health, enabling timely routine upkeep while minimizing costly emergency interventions. Prioritizing preventive actions based on risk assessment and historical data optimizes resource allocation and extends asset lifespan.

Conclusion and Recommendations

Routine maintenance ensures consistent equipment performance and prevents costly breakdowns by addressing issues proactively. Emergency maintenance, while necessary for unplanned failures, leads to higher repair costs and operational downtime. Implementing a robust routine maintenance schedule is recommended to minimize emergencies and optimize asset longevity.

Routine Maintenance vs Emergency Maintenance Infographic

jobdiv.com

jobdiv.com