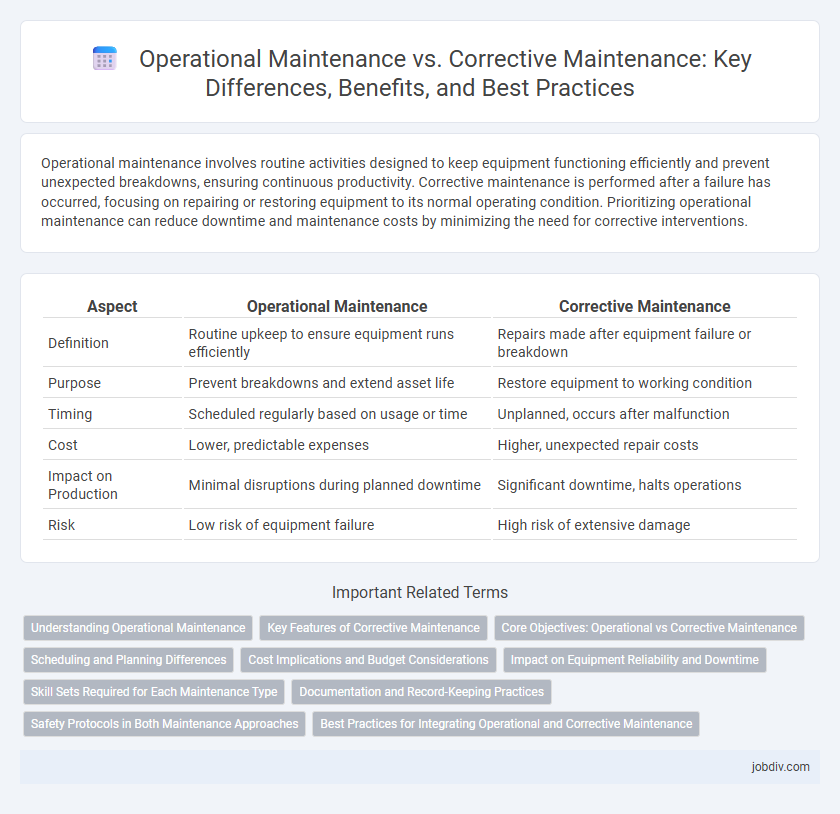

Operational maintenance involves routine activities designed to keep equipment functioning efficiently and prevent unexpected breakdowns, ensuring continuous productivity. Corrective maintenance is performed after a failure has occurred, focusing on repairing or restoring equipment to its normal operating condition. Prioritizing operational maintenance can reduce downtime and maintenance costs by minimizing the need for corrective interventions.

Table of Comparison

| Aspect | Operational Maintenance | Corrective Maintenance |

|---|---|---|

| Definition | Routine upkeep to ensure equipment runs efficiently | Repairs made after equipment failure or breakdown |

| Purpose | Prevent breakdowns and extend asset life | Restore equipment to working condition |

| Timing | Scheduled regularly based on usage or time | Unplanned, occurs after malfunction |

| Cost | Lower, predictable expenses | Higher, unexpected repair costs |

| Impact on Production | Minimal disruptions during planned downtime | Significant downtime, halts operations |

| Risk | Low risk of equipment failure | High risk of extensive damage |

Understanding Operational Maintenance

Operational maintenance focuses on routine tasks that ensure equipment and systems function efficiently, preventing unexpected breakdowns and extending asset lifespan. This proactive approach includes activities such as inspections, lubrication, adjustments, and cleaning to maintain optimal performance. Understanding operational maintenance is crucial for reducing downtime and minimizing costly repairs by addressing potential issues before they escalate.

Key Features of Corrective Maintenance

Corrective maintenance focuses on repairing equipment after a failure has occurred, minimizing downtime by restoring functionality as quickly as possible. Key features include reactive execution, unplanned activities, and urgent troubleshooting to address unexpected faults. This approach contrasts with operational maintenance by prioritizing immediate fix actions rather than routine inspections or preventive measures.

Core Objectives: Operational vs Corrective Maintenance

Operational maintenance focuses on routine inspections and preventive measures to ensure consistent equipment performance, minimizing unplanned downtime and extending asset lifespan. Corrective maintenance targets the rapid identification and repair of unexpected faults or failures to restore functionality and reduce production losses. Both strategies aim to optimize asset reliability but differ in timing and approach to managing equipment health.

Scheduling and Planning Differences

Operational maintenance emphasizes scheduled, routine activities designed to prevent equipment failures and ensure consistent performance, relying heavily on predictive analytics for timely interventions. Corrective maintenance occurs in response to unexpected equipment breakdowns, requiring immediate, often unscheduled repairs without prior planning, which can lead to downtime. Effective scheduling in operational maintenance minimizes disruptions through planned downtime, whereas corrective maintenance necessitates reactive scheduling to restore functionality as quickly as possible.

Cost Implications and Budget Considerations

Operational maintenance, which involves regular inspections and preventive tasks, typically reduces long-term costs by minimizing equipment downtime and extending asset lifespan. Corrective maintenance often incurs higher expenses due to emergency repairs, unplanned labor, and potential production losses, making budgeting more unpredictable. Allocating funds towards operational maintenance can optimize budget efficiency and decrease overall maintenance expenditures.

Impact on Equipment Reliability and Downtime

Operational maintenance proactively ensures equipment reliability by performing scheduled inspections and adjustments that prevent failures. Corrective maintenance addresses unexpected breakdowns, often causing extended downtime due to emergency repairs. Emphasizing operational maintenance significantly reduces unplanned downtime and enhances overall equipment lifespan.

Skill Sets Required for Each Maintenance Type

Operational maintenance requires technicians to possess strong preventive skills, including routine inspection, lubrication, and calibration, to ensure equipment reliability and avoid breakdowns. Corrective maintenance demands advanced diagnostic abilities, problem-solving expertise, and proficiency in repair techniques to quickly address unexpected failures and restore functionality. Both maintenance types benefit from a solid understanding of equipment mechanics and safety protocols, but the emphasis on proactive versus reactive skills differentiates their training and expertise requirements.

Documentation and Record-Keeping Practices

Operational maintenance involves systematic documentation of routine inspections, scheduled servicing, and condition monitoring to ensure optimal equipment performance and prevent unexpected downtime. Corrective maintenance records focus on detailed fault analysis, repair actions taken, and root cause identification to facilitate future prevention and improve maintenance strategies. Accurate and comprehensive record-keeping in both maintenance types supports data-driven decision-making and regulatory compliance.

Safety Protocols in Both Maintenance Approaches

Operational maintenance emphasizes proactive safety protocols, including routine inspections and preventive measures that minimize equipment failure and reduce workplace accidents. Corrective maintenance prioritizes immediate hazard identification and containment to address unexpected breakdowns swiftly, ensuring personnel protection and safe restoration of functionality. Both approaches integrate strict compliance with regulatory safety standards to maintain a secure environment throughout maintenance activities.

Best Practices for Integrating Operational and Corrective Maintenance

Effective integration of operational and corrective maintenance involves implementing predictive analytics and condition monitoring to anticipate failures and streamline repairs. Establishing a centralized maintenance management system enhances data sharing and coordination between teams, reducing downtime and improving asset lifespan. Training personnel on both maintenance strategies ensures quick response to failures while maintaining routine operational standards.

Operational Maintenance vs Corrective Maintenance Infographic

jobdiv.com

jobdiv.com