Shutdown maintenance involves halting operations to perform thorough inspections, repairs, or upgrades, ensuring equipment reliability and safety during non-production periods. Running maintenance, also known as predictive or condition-based maintenance, allows machinery to continue operating while monitoring performance and addressing issues in real-time to minimize downtime. Choosing between shutdown and running maintenance depends on balancing operational demands with the need for equipment longevity and efficiency.

Table of Comparison

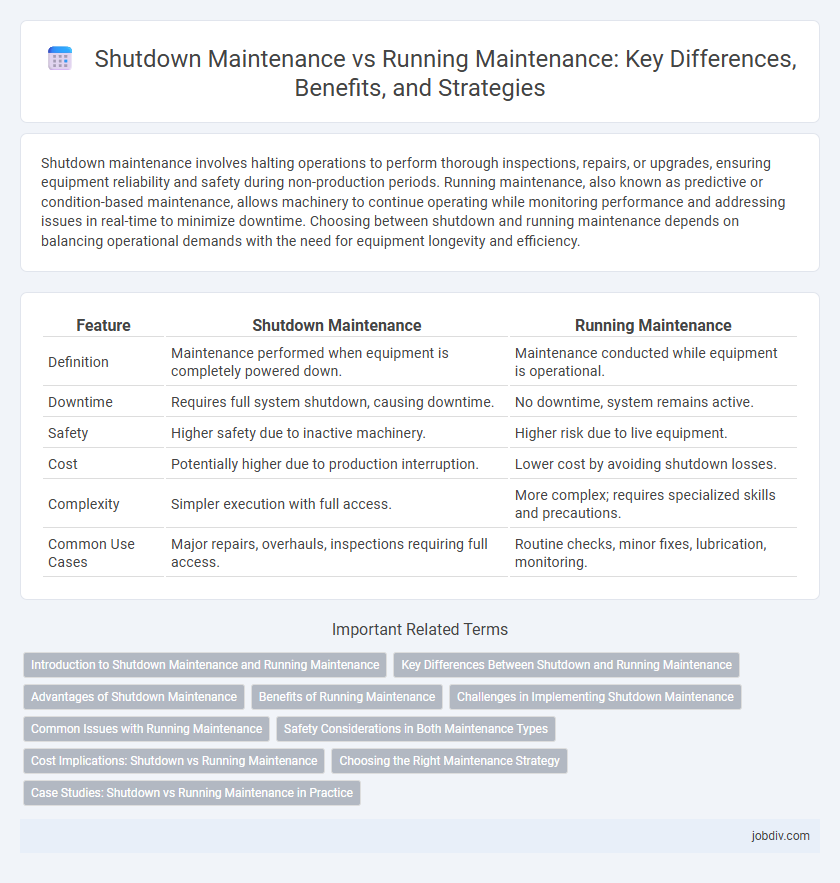

| Feature | Shutdown Maintenance | Running Maintenance |

|---|---|---|

| Definition | Maintenance performed when equipment is completely powered down. | Maintenance conducted while equipment is operational. |

| Downtime | Requires full system shutdown, causing downtime. | No downtime, system remains active. |

| Safety | Higher safety due to inactive machinery. | Higher risk due to live equipment. |

| Cost | Potentially higher due to production interruption. | Lower cost by avoiding shutdown losses. |

| Complexity | Simpler execution with full access. | More complex; requires specialized skills and precautions. |

| Common Use Cases | Major repairs, overhauls, inspections requiring full access. | Routine checks, minor fixes, lubrication, monitoring. |

Introduction to Shutdown Maintenance and Running Maintenance

Shutdown Maintenance involves halting operations to perform thorough inspections, repairs, and upgrades, ensuring safety and extending equipment lifespan. Running Maintenance, also known as online or condition-based maintenance, is conducted without stopping production, focusing on monitoring and addressing issues in real-time to minimize downtime. Both approaches balance operational efficiency and asset reliability, with Shutdown Maintenance typically scheduled for major overhauls and Running Maintenance applied for routine checks and minor interventions.

Key Differences Between Shutdown and Running Maintenance

Shutdown maintenance requires stopping machinery or systems entirely for thorough inspection, repairs, and upgrades, ensuring comprehensive safety and effectiveness. Running maintenance occurs while equipment remains operational, focusing on minor repairs and adjustments to prevent breakdowns without halting production. Key differences include operational downtime, with shutdown maintenance causing planned outages, whereas running maintenance prioritizes continuous workflow and immediate issue resolution.

Advantages of Shutdown Maintenance

Shutdown maintenance allows for comprehensive inspection and repair of equipment, reducing the risk of unexpected failures and extending asset lifespan. It ensures safety by eliminating operational hazards during maintenance tasks, which is crucial in high-risk industries like manufacturing and power generation. Performing maintenance during shutdowns minimizes production disruptions and enhances long-term operational efficiency by addressing issues thoroughly.

Benefits of Running Maintenance

Running maintenance minimizes production downtime by allowing essential repairs and inspections to occur without halting operations. This approach enhances equipment longevity, reduces unexpected failures, and promotes continuous productivity. Implementing running maintenance strategies leads to cost savings by avoiding the losses associated with full shutdowns.

Challenges in Implementing Shutdown Maintenance

Shutdown maintenance demands thorough planning to minimize production loss, presenting challenges such as scheduling downtime without impacting operational targets. Resource allocation becomes critical, as skilled personnel and specialized equipment must be available simultaneously within a limited timeframe. Unforeseen technical issues during shutdown further complicate the execution, increasing the risk of extended outages and higher costs.

Common Issues with Running Maintenance

Running maintenance often leads to common issues such as system instability, increased risk of hardware failure, and incomplete software updates due to ongoing operations. These challenges can cause prolonged downtime, reduced performance, and potential data corruption. Proper planning and real-time monitoring are essential to mitigate risks during running maintenance activities.

Safety Considerations in Both Maintenance Types

Shutdown maintenance involves halting operations completely, allowing technicians to perform thorough inspections and repairs with minimized risk of accidental injury from active machinery. Running maintenance requires strict safety protocols including lockout/tagout procedures, continuous monitoring, and use of personal protective equipment to protect workers from moving parts and electrical hazards. Both maintenance types prioritize safety, but shutdown maintenance inherently reduces exposure to operational hazards by isolating all energy sources before work begins.

Cost Implications: Shutdown vs Running Maintenance

Shutdown maintenance typically incurs higher direct costs due to production halts, labor overtime, and expedited parts procurement, whereas running maintenance spreads expenses over time with lower immediate financial impact. Investing in running maintenance reduces downtime-related losses and extends asset lifespan, optimizing overall operational expenditure. Balancing shutdown and running maintenance strategies minimizes long-term costs by aligning maintenance activities with production schedules and resource availability.

Choosing the Right Maintenance Strategy

Selecting the right maintenance strategy hinges on balancing operational efficiency and equipment reliability; shutdown maintenance ensures comprehensive inspections and repairs but requires planned downtime, while running maintenance allows for ongoing operation with targeted interventions to minimize disruptions. Evaluating factors such as equipment criticality, failure risk, and production demands guides the decision between preventive shutdowns and predictive or condition-based maintenance during operation. Optimal asset management leverages data analytics and real-time monitoring to determine when shutdown maintenance is essential versus when running maintenance suffices to maintain performance and extend equipment lifespan.

Case Studies: Shutdown vs Running Maintenance in Practice

Case studies comparing shutdown maintenance and running maintenance reveal significant differences in operational efficiency and cost-effectiveness across industries. Shutdown maintenance often results in higher immediate downtime costs but allows for comprehensive inspections and repairs, reducing long-term failure risks. Running maintenance minimizes production losses by performing repairs during operation but requires advanced monitoring technologies to prevent unexpected breakdowns and ensure safety.

Shutdown Maintenance vs Running Maintenance Infographic

jobdiv.com

jobdiv.com