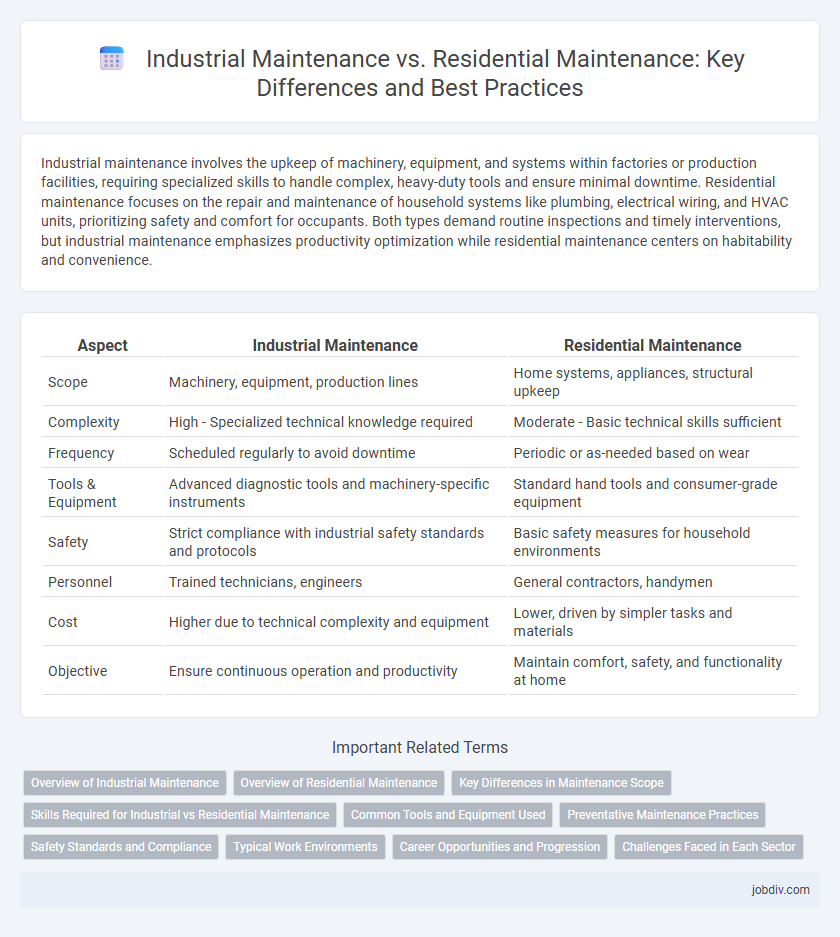

Industrial maintenance involves the upkeep of machinery, equipment, and systems within factories or production facilities, requiring specialized skills to handle complex, heavy-duty tools and ensure minimal downtime. Residential maintenance focuses on the repair and maintenance of household systems like plumbing, electrical wiring, and HVAC units, prioritizing safety and comfort for occupants. Both types demand routine inspections and timely interventions, but industrial maintenance emphasizes productivity optimization while residential maintenance centers on habitability and convenience.

Table of Comparison

| Aspect | Industrial Maintenance | Residential Maintenance |

|---|---|---|

| Scope | Machinery, equipment, production lines | Home systems, appliances, structural upkeep |

| Complexity | High - Specialized technical knowledge required | Moderate - Basic technical skills sufficient |

| Frequency | Scheduled regularly to avoid downtime | Periodic or as-needed based on wear |

| Tools & Equipment | Advanced diagnostic tools and machinery-specific instruments | Standard hand tools and consumer-grade equipment |

| Safety | Strict compliance with industrial safety standards and protocols | Basic safety measures for household environments |

| Personnel | Trained technicians, engineers | General contractors, handymen |

| Cost | Higher due to technical complexity and equipment | Lower, driven by simpler tasks and materials |

| Objective | Ensure continuous operation and productivity | Maintain comfort, safety, and functionality at home |

Overview of Industrial Maintenance

Industrial maintenance involves the systematic inspection, repair, and upkeep of machinery and equipment used in manufacturing and production facilities, ensuring operational efficiency and minimizing downtime. It encompasses preventive, predictive, and corrective maintenance strategies tailored to complex industrial systems such as HVAC, conveyor belts, and robotic automation. Effective industrial maintenance reduces costly breakdowns, extends equipment lifespan, and supports safety compliance in high-demand environments.

Overview of Residential Maintenance

Residential maintenance involves regular upkeep tasks to ensure safe, comfortable, and efficient living environments, including HVAC system servicing, plumbing repairs, and electrical inspections. Emphasis is placed on preventative measures to avoid costly breakdowns and extend the lifespan of home components. Unlike industrial maintenance, it prioritizes occupant safety, compliance with housing codes, and energy efficiency in smaller-scale systems.

Key Differences in Maintenance Scope

Industrial maintenance involves managing complex machinery, heavy equipment, and large-scale systems essential for production processes, focusing on minimizing downtime and ensuring safety compliance. Residential maintenance typically covers smaller-scale tasks such as HVAC servicing, plumbing repairs, and electrical system upkeep to maintain comfort and functionality in homes. The key difference lies in the scale, complexity, and regulatory requirements, with industrial maintenance demanding specialized expertise and stringent standards compared to the more routine, general upkeep in residential settings.

Skills Required for Industrial vs Residential Maintenance

Industrial maintenance requires specialized technical skills such as understanding complex machinery, electrical systems, and automation technologies, alongside proficiency in preventative maintenance and diagnostics. Residential maintenance primarily involves basic repair skills, plumbing, electrical work, and routine upkeep tasks tailored to home environments. Both fields demand problem-solving abilities, but industrial maintenance professionals must handle higher safety standards and advanced equipment expertise.

Common Tools and Equipment Used

Industrial maintenance typically utilizes heavy-duty tools such as hydraulic lifts, vibration analyzers, and industrial-grade power drills designed for large-scale machinery repair. In contrast, residential maintenance relies on more compact, versatile tools like cordless drills, pipe wrenches, and multimeters suited for smaller systems and household appliances. Both sectors benefit from safety gear including gloves, safety glasses, and multimeters to ensure efficient and secure maintenance operations.

Preventative Maintenance Practices

Industrial maintenance emphasizes rigorous preventative maintenance practices such as scheduled inspections, lubrication, and equipment calibration to minimize downtime and extend machinery lifespan. In residential maintenance, preventative efforts focus on routine tasks like HVAC filter changes, plumbing inspections, and roof assessments to avoid costly repairs and improve home safety. Both sectors prioritize early fault detection and regular upkeep to enhance operational efficiency and reduce emergency intervention costs.

Safety Standards and Compliance

Industrial maintenance strictly adheres to rigorous safety standards such as OSHA regulations and ANSI codes to ensure worker protection and prevent costly downtime in complex machinery environments. Residential maintenance generally follows local building codes and safety guidelines focused on occupant well-being and structural integrity, often overseen by municipal authorities. Compliance in industrial settings demands specialized training and certifications, while residential maintenance prioritizes accessibility and ease of inspection for homeowners and contractors.

Typical Work Environments

Industrial maintenance typically occurs in manufacturing plants, factories, and large-scale facilities equipped with heavy machinery, complex systems, and specialized equipment requiring routine inspections and repairs. Residential maintenance, on the other hand, is performed in homes, apartments, and small residential buildings, focusing on HVAC systems, plumbing, electrical repairs, and general upkeep. The industrial environment demands adherence to strict safety protocols and regulatory standards due to high-risk machinery, whereas residential maintenance prioritizes occupant comfort and accessibility.

Career Opportunities and Progression

Industrial maintenance careers offer specialization in complex machinery, automation systems, and large-scale facilities, leading to higher earning potential and leadership roles in manufacturing or utilities sectors. Residential maintenance professionals focus on plumbing, electrical, and HVAC systems in homes, providing steady demand and opportunities in property management or home inspection fields. Progression in industrial maintenance often involves certifications like PLC programming, while residential roles may advance through contractor licensing and small business ownership.

Challenges Faced in Each Sector

Industrial maintenance often grapples with managing complex machinery, ensuring minimal downtime, and adhering to strict safety regulations in high-risk environments. Residential maintenance faces challenges such as varied repair needs, balancing cost constraints, and coordinating with multiple service providers for plumbing, electrical, and structural issues. Both sectors require specialized knowledge, but industrial maintenance demands more rigorous preventive strategies to sustain production efficiency.

Industrial Maintenance vs Residential Maintenance Infographic

jobdiv.com

jobdiv.com