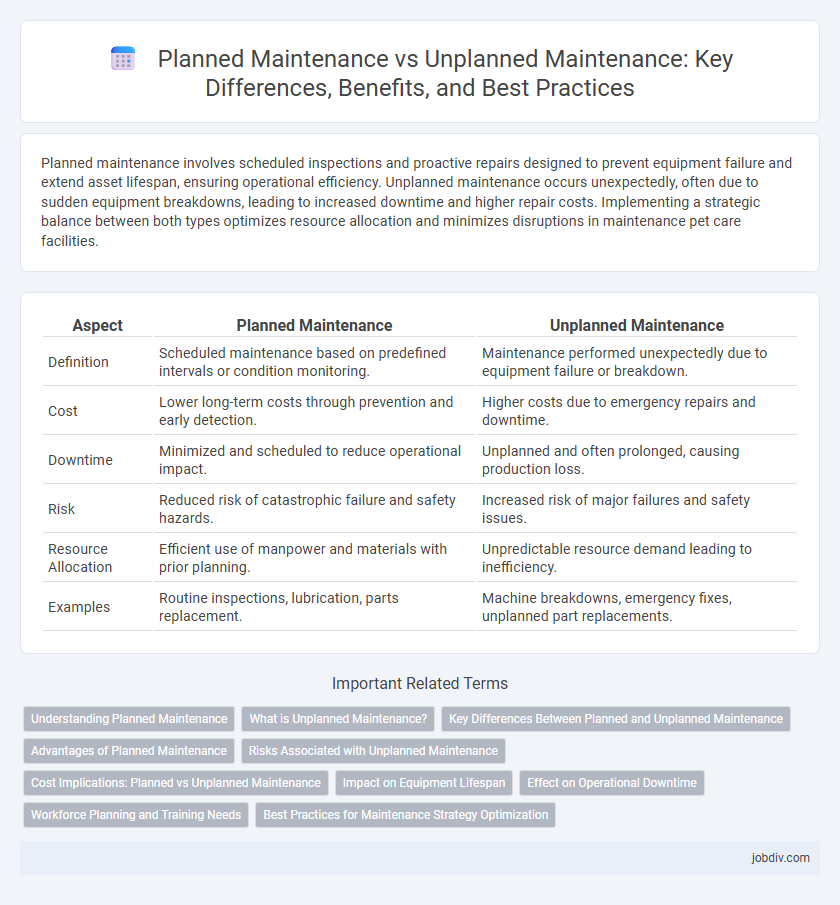

Planned maintenance involves scheduled inspections and proactive repairs designed to prevent equipment failure and extend asset lifespan, ensuring operational efficiency. Unplanned maintenance occurs unexpectedly, often due to sudden equipment breakdowns, leading to increased downtime and higher repair costs. Implementing a strategic balance between both types optimizes resource allocation and minimizes disruptions in maintenance pet care facilities.

Table of Comparison

| Aspect | Planned Maintenance | Unplanned Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on predefined intervals or condition monitoring. | Maintenance performed unexpectedly due to equipment failure or breakdown. |

| Cost | Lower long-term costs through prevention and early detection. | Higher costs due to emergency repairs and downtime. |

| Downtime | Minimized and scheduled to reduce operational impact. | Unplanned and often prolonged, causing production loss. |

| Risk | Reduced risk of catastrophic failure and safety hazards. | Increased risk of major failures and safety issues. |

| Resource Allocation | Efficient use of manpower and materials with prior planning. | Unpredictable resource demand leading to inefficiency. |

| Examples | Routine inspections, lubrication, parts replacement. | Machine breakdowns, emergency fixes, unplanned part replacements. |

Understanding Planned Maintenance

Planned maintenance involves scheduled inspections, servicing, and repairs to prevent equipment failures and extend asset lifespan. It relies on historical data, manufacturer recommendations, and condition monitoring to anticipate issues before they occur. This proactive approach reduces downtime and optimizes operational efficiency in industrial settings.

What is Unplanned Maintenance?

Unplanned maintenance refers to unexpected repairs or interventions that occur without prior scheduling, often triggered by equipment failure or breakdown. This type of maintenance disrupts normal operations and can lead to costly downtime, reduced productivity, and increased emergency repair expenses. Organizations aim to minimize unplanned maintenance through predictive and preventive strategies to enhance asset reliability and operational efficiency.

Key Differences Between Planned and Unplanned Maintenance

Planned maintenance involves scheduled inspections and repairs based on predefined intervals or usage metrics, ensuring equipment reliability and minimizing operational downtime. Unplanned maintenance occurs unexpectedly, often triggered by equipment failures or breakdowns, resulting in higher costs and disruption to production schedules. Key differences include predictability, cost efficiency, and the impact on operational continuity, with planned maintenance emphasizing prevention and unplanned maintenance focusing on reactive problem-solving.

Advantages of Planned Maintenance

Planned maintenance enhances equipment reliability by scheduling regular inspections and repairs, reducing the risk of unexpected breakdowns. It optimizes resource allocation, minimizes downtime, and extends asset lifespan through systematic upkeep. Implementing planned maintenance improves operational efficiency and lowers overall maintenance costs by preventing emergency repairs and prolonging machinery performance.

Risks Associated with Unplanned Maintenance

Unplanned maintenance poses significant risks including unexpected equipment failures, increased downtime, and higher repair costs due to the urgency and lack of preparation. These risks can lead to production losses, safety hazards for workers, and diminished asset lifespan. In contrast, planned maintenance reduces these risks through scheduled inspections and proactive repairs, ensuring operational efficiency and reliability.

Cost Implications: Planned vs Unplanned Maintenance

Planned maintenance minimizes unexpected equipment failures and reduces emergency repair costs, leading to significant savings in labor and parts expenses over time. Unplanned maintenance often incurs higher costs due to urgent repairs, overtime labor, and potential production downtime, which can disrupt operational efficiency and increase overall expenses. Investing in scheduled maintenance strategies enhances asset reliability and cost predictability, ultimately lowering the total cost of ownership.

Impact on Equipment Lifespan

Planned maintenance significantly extends equipment lifespan by addressing wear and potential failures proactively, reducing downtime and costly repairs. Unplanned maintenance often leads to accelerated equipment degradation due to unexpected breakdowns and delayed repairs, increasing the risk of permanent damage. Implementing structured maintenance schedules optimizes asset reliability and maximizes operational efficiency.

Effect on Operational Downtime

Planned maintenance significantly reduces operational downtime by scheduling repairs and inspections during non-peak hours, ensuring equipment reliability and preventing unexpected failures. Unplanned maintenance often results in prolonged downtime due to sudden equipment breakdowns, disrupting production schedules and increasing repair costs. Optimizing planned maintenance strategies enhances overall operational efficiency and minimizes financial losses associated with unscheduled outages.

Workforce Planning and Training Needs

Planned maintenance enables optimized workforce planning by scheduling tasks during low-production periods, reducing downtime and improving resource allocation efficiency. It allows targeted training programs for technicians, ensuring they possess the necessary skills and certifications before maintenance activities begin. Unplanned maintenance often creates urgent workforce demands and skill gaps, highlighting the need for rapid cross-training and flexible staffing strategies to address unexpected failures effectively.

Best Practices for Maintenance Strategy Optimization

Implementing a balanced maintenance strategy that prioritizes planned maintenance reduces equipment downtime and extends asset lifespan, enhancing overall operational efficiency. Utilizing predictive analytics and condition monitoring tools enables early detection of potential failures, preventing costly unplanned maintenance disruptions. Regularly reviewing maintenance data and adjusting schedules based on performance metrics ensures continuous optimization of resources and maintenance effectiveness.

Planned Maintenance vs Unplanned Maintenance Infographic

jobdiv.com

jobdiv.com