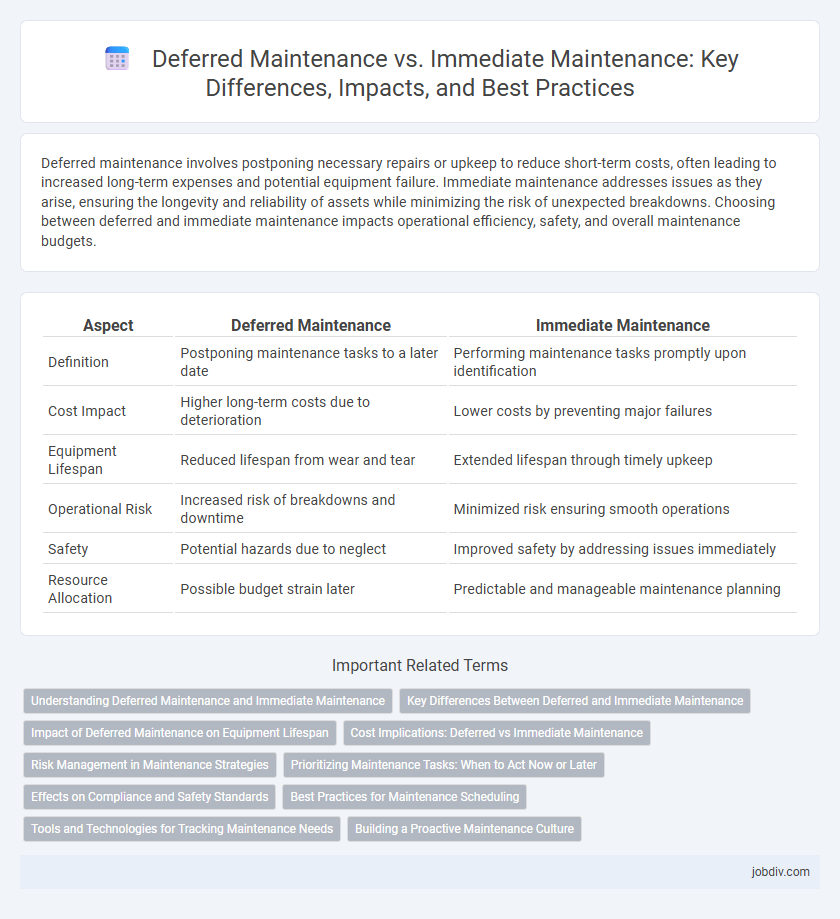

Deferred maintenance involves postponing necessary repairs or upkeep to reduce short-term costs, often leading to increased long-term expenses and potential equipment failure. Immediate maintenance addresses issues as they arise, ensuring the longevity and reliability of assets while minimizing the risk of unexpected breakdowns. Choosing between deferred and immediate maintenance impacts operational efficiency, safety, and overall maintenance budgets.

Table of Comparison

| Aspect | Deferred Maintenance | Immediate Maintenance |

|---|---|---|

| Definition | Postponing maintenance tasks to a later date | Performing maintenance tasks promptly upon identification |

| Cost Impact | Higher long-term costs due to deterioration | Lower costs by preventing major failures |

| Equipment Lifespan | Reduced lifespan from wear and tear | Extended lifespan through timely upkeep |

| Operational Risk | Increased risk of breakdowns and downtime | Minimized risk ensuring smooth operations |

| Safety | Potential hazards due to neglect | Improved safety by addressing issues immediately |

| Resource Allocation | Possible budget strain later | Predictable and manageable maintenance planning |

Understanding Deferred Maintenance and Immediate Maintenance

Deferred maintenance refers to the postponement of necessary repairs or upkeep activities due to budget constraints or operational priorities, often leading to increased long-term costs and reduced asset lifespan. Immediate maintenance involves addressing issues as soon as they are detected, ensuring equipment reliability, safety, and optimal performance. Understanding the balance between deferred and immediate maintenance helps organizations optimize resource allocation and minimize downtime.

Key Differences Between Deferred and Immediate Maintenance

Deferred maintenance involves postponing repairs or upkeep tasks due to budget constraints or low urgency, often leading to increased long-term costs and asset deterioration. Immediate maintenance requires prompt attention to fix issues as they arise, ensuring optimal equipment functionality and preventing unexpected failures. Key differences include cost impact, risk level, and asset lifespan, with immediate maintenance reducing downtime and preserving value more effectively than deferred maintenance.

Impact of Deferred Maintenance on Equipment Lifespan

Deferred maintenance significantly reduces equipment lifespan by allowing minor issues to escalate into major failures, increasing wear and tear. Immediate maintenance preserves asset functionality and prevents costly breakdowns, ensuring optimal performance and longevity. Prioritizing timely repairs minimizes downtime and lowers overall lifecycle costs of machinery.

Cost Implications: Deferred vs Immediate Maintenance

Deferred maintenance often leads to higher long-term costs due to deterioration and more extensive repairs, while immediate maintenance minimizes expenses by addressing issues promptly. Immediate maintenance enhances asset lifespan and operational efficiency, reducing unexpected breakdowns and emergency repair costs. Investing in timely maintenance lowers overall expenditure compared to the compounded cost increases associated with deferring repairs.

Risk Management in Maintenance Strategies

Deferred maintenance increases the risk of equipment failure and unexpected downtime, leading to higher repair costs and safety hazards. Immediate maintenance mitigates operational risks by ensuring timely repairs and system reliability, which supports continuous production and reduces long-term expenses. Effective risk management in maintenance strategies balances the cost implications of deferred actions against the potential for catastrophic failures.

Prioritizing Maintenance Tasks: When to Act Now or Later

Prioritizing maintenance tasks relies on assessing the urgency and impact of equipment conditions, where immediate maintenance addresses critical failures to prevent downtime and safety hazards. Deferred maintenance involves scheduling less urgent repairs to optimize resources and budget without compromising overall system performance. Effective maintenance strategies balance these approaches by analyzing risk, cost, and operational priorities to decide when to act now or later.

Effects on Compliance and Safety Standards

Deferred maintenance often leads to non-compliance with industry regulations and compromises safety standards due to deteriorating equipment and infrastructure. Immediate maintenance ensures adherence to compliance requirements and mitigates risks by addressing issues before they escalate. Ignoring urgent repairs increases the likelihood of accidents, regulatory penalties, and operational disruptions.

Best Practices for Maintenance Scheduling

Effective maintenance scheduling balances deferred maintenance with immediate maintenance to optimize asset lifespan and operational efficiency. Best practices include prioritizing tasks based on risk assessments, equipment criticality, and resource availability, ensuring urgent repairs are addressed promptly while less critical issues are scheduled during planned downtimes. Implementing a computerized maintenance management system (CMMS) enhances visibility, tracks maintenance history, and facilitates data-driven decisions for optimal scheduling.

Tools and Technologies for Tracking Maintenance Needs

Deferred maintenance often relies on basic tools such as manual logs and spreadsheets, which can lead to inefficiencies and missed deadlines. Immediate maintenance benefits from advanced technologies like Computerized Maintenance Management Systems (CMMS), IoT sensors, and predictive analytics that provide real-time tracking and automated alerts. These tools enhance accuracy in maintenance scheduling, reduce downtime, and optimize resource allocation.

Building a Proactive Maintenance Culture

Implementing a proactive maintenance culture involves prioritizing immediate maintenance over deferred maintenance to prevent costly equipment failures and extend asset lifespan. Immediate maintenance addresses issues promptly, minimizing downtime and enhancing operational efficiency, while deferred maintenance often leads to escalated repair costs and safety risks. Leveraging predictive analytics and real-time monitoring tools ensures timely interventions, fostering sustainability and reliability within facility management.

Deferred Maintenance vs Immediate Maintenance Infographic

jobdiv.com

jobdiv.com