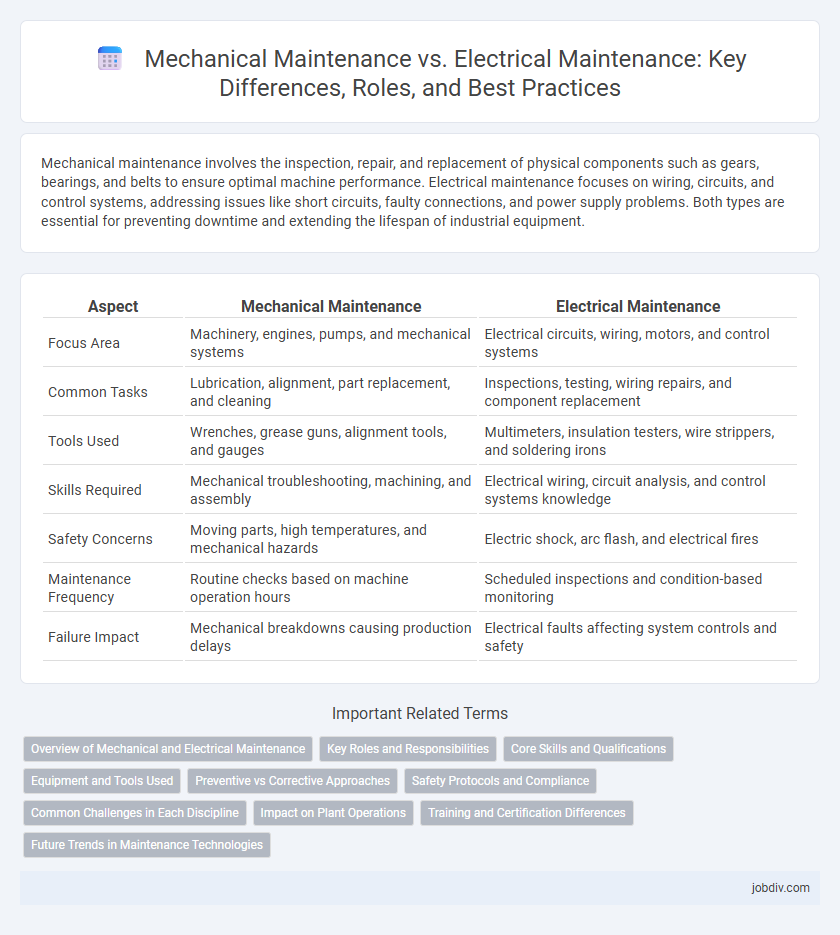

Mechanical maintenance involves the inspection, repair, and replacement of physical components such as gears, bearings, and belts to ensure optimal machine performance. Electrical maintenance focuses on wiring, circuits, and control systems, addressing issues like short circuits, faulty connections, and power supply problems. Both types are essential for preventing downtime and extending the lifespan of industrial equipment.

Table of Comparison

| Aspect | Mechanical Maintenance | Electrical Maintenance |

|---|---|---|

| Focus Area | Machinery, engines, pumps, and mechanical systems | Electrical circuits, wiring, motors, and control systems |

| Common Tasks | Lubrication, alignment, part replacement, and cleaning | Inspections, testing, wiring repairs, and component replacement |

| Tools Used | Wrenches, grease guns, alignment tools, and gauges | Multimeters, insulation testers, wire strippers, and soldering irons |

| Skills Required | Mechanical troubleshooting, machining, and assembly | Electrical wiring, circuit analysis, and control systems knowledge |

| Safety Concerns | Moving parts, high temperatures, and mechanical hazards | Electric shock, arc flash, and electrical fires |

| Maintenance Frequency | Routine checks based on machine operation hours | Scheduled inspections and condition-based monitoring |

| Failure Impact | Mechanical breakdowns causing production delays | Electrical faults affecting system controls and safety |

Overview of Mechanical and Electrical Maintenance

Mechanical maintenance involves the upkeep and repair of machinery, engines, and mechanical systems to ensure optimal performance and prevent breakdowns. Electrical maintenance focuses on inspecting, testing, and repairing electrical components, wiring, and systems to ensure safety and continuous operation. Both disciplines require specialized skills and regular preventive measures to minimize downtime and extend equipment lifespan.

Key Roles and Responsibilities

Mechanical maintenance involves routine inspection, lubrication, and repair of machinery components such as bearings, gears, and hydraulic systems to ensure optimal equipment performance and prevent mechanical failures. Electrical maintenance focuses on diagnosing electrical faults, performing preventive checks on wiring, circuits, and control systems, and ensuring compliance with safety standards to maintain uninterrupted power and control operations. Both roles require expertise in troubleshooting, adherence to safety protocols, and documentation of maintenance activities to support asset reliability and operational efficiency.

Core Skills and Qualifications

Mechanical maintenance requires expertise in hydraulics, pneumatics, and mechanical systems, along with skills in diagnosing wear and tear and performing component replacements. Electrical maintenance demands knowledge of circuitry, electrical schematics, and safety protocols, coupled with qualifications in handling electrical testing equipment and troubleshooting faults. Both disciplines require proficiency in interpreting technical manuals and adherence to industry standards for preventive and corrective maintenance.

Equipment and Tools Used

Mechanical maintenance relies heavily on tools such as torque wrenches, hydraulic jacks, and precision gauges to service gears, bearings, and engine components. Electrical maintenance primarily uses multimeters, insulation testers, and circuit analyzers to inspect wiring, switches, and control panels. Both disciplines require specialized diagnostic instruments to ensure optimal equipment functionality and prevent downtime.

Preventive vs Corrective Approaches

Mechanical maintenance primarily involves preventive strategies such as regular lubrication, alignment, and inspection to avoid equipment failure, while electrical maintenance emphasizes routine testing, calibration, and insulation checks to prevent circuit faults. Corrective maintenance in mechanical systems often requires part replacements and structural repairs due to wear and tear, whereas electrical corrective tasks include troubleshooting wiring issues and component restorations after breakdowns. Implementing preventive maintenance in both domains enhances equipment reliability, reduces downtime, and lowers overall repair costs compared to reactive corrective interventions.

Safety Protocols and Compliance

Mechanical maintenance requires strict adherence to safety protocols such as lockout/tagout procedures, use of personal protective equipment (PPE), and regular machine inspections to prevent injuries from moving parts. Electrical maintenance emphasizes compliance with standards like NFPA 70E and OSHA regulations, ensuring proper de-energization, grounding, and use of insulated tools to mitigate electrical hazards. Both disciplines mandate comprehensive training and safety audits to maintain regulatory compliance and protect maintenance personnel.

Common Challenges in Each Discipline

Mechanical maintenance often faces challenges such as wear and tear of moving parts, misalignment, and lubrication failures, which can lead to unexpected breakdowns and reduced equipment lifespan. Electrical maintenance commonly struggles with issues like wiring faults, insulation degradation, and circuit failures, increasing the risk of electrical fires and system downtime. Both disciplines require specialized diagnostic tools and skilled technicians to effectively identify and resolve these problems to ensure operational reliability.

Impact on Plant Operations

Mechanical maintenance directly affects the physical machinery, reducing downtime caused by wear and tear, lubrication failures, or mechanical breakdowns, thus ensuring consistent plant operation. Electrical maintenance targets the control systems, wiring, and power distribution, preventing disruptions due to electrical faults, circuit failures, or automation errors, which are critical for uninterrupted processes. Both disciplines are essential for optimal plant performance, with mechanical maintenance safeguarding equipment longevity and electrical maintenance ensuring system reliability.

Training and Certification Differences

Mechanical maintenance technicians often require certifications such as Certified Maintenance & Reliability Technician (CMRT) or mechanical-specific training programs emphasizing hydraulics, pneumatics, and machinery repair. Electrical maintenance professionals typically pursue certifications like the Certified Electrical Maintenance Technician (CEMT) or National Electrical Code (NEC) training, focusing on electrical systems, wiring, and circuit troubleshooting. Training for mechanical roles prioritizes hands-on skills with moving parts and mechanical components, whereas electrical roles emphasize safety protocols and electrical system diagnostics.

Future Trends in Maintenance Technologies

Mechanical maintenance is evolving with the integration of predictive analytics and IoT sensors that enable real-time monitoring of machine health, reducing downtime and improving efficiency. Electrical maintenance increasingly relies on AI-powered diagnostics and advanced automation systems to detect faults early and optimize energy consumption. Future trends emphasize the convergence of mechanical and electrical maintenance through digital twin technology, enhancing precision and proactive decision-making in industrial environments.

Mechanical Maintenance vs Electrical Maintenance Infographic

jobdiv.com

jobdiv.com