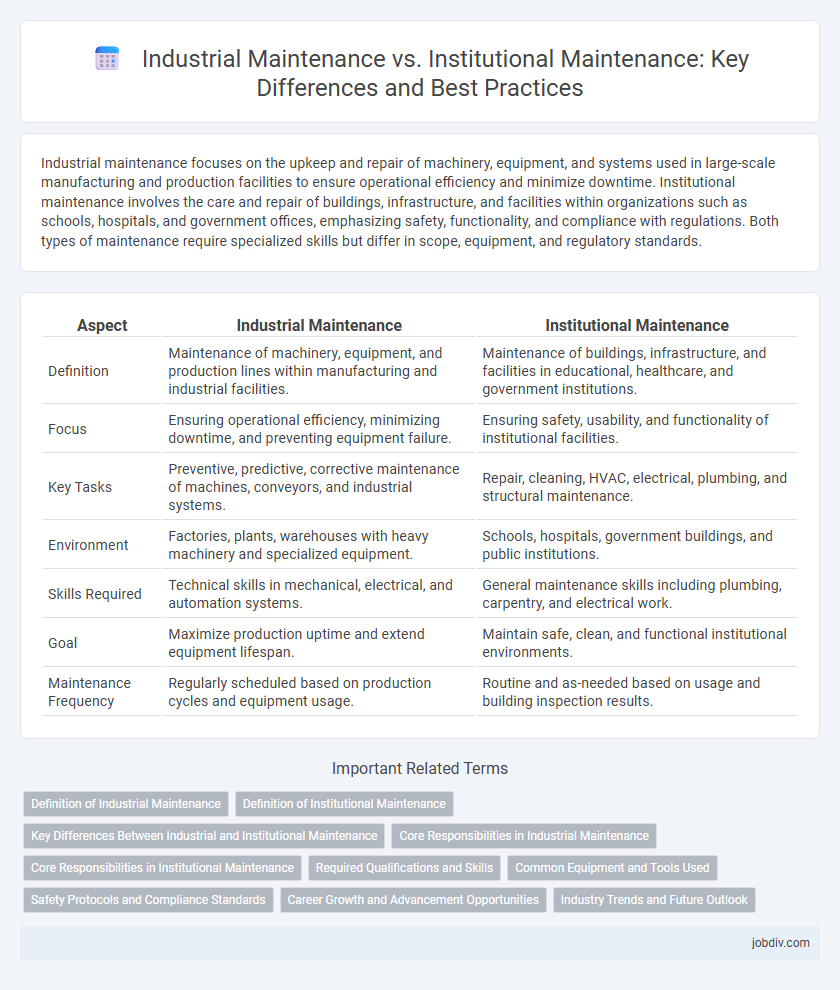

Industrial maintenance focuses on the upkeep and repair of machinery, equipment, and systems used in large-scale manufacturing and production facilities to ensure operational efficiency and minimize downtime. Institutional maintenance involves the care and repair of buildings, infrastructure, and facilities within organizations such as schools, hospitals, and government offices, emphasizing safety, functionality, and compliance with regulations. Both types of maintenance require specialized skills but differ in scope, equipment, and regulatory standards.

Table of Comparison

| Aspect | Industrial Maintenance | Institutional Maintenance |

|---|---|---|

| Definition | Maintenance of machinery, equipment, and production lines within manufacturing and industrial facilities. | Maintenance of buildings, infrastructure, and facilities in educational, healthcare, and government institutions. |

| Focus | Ensuring operational efficiency, minimizing downtime, and preventing equipment failure. | Ensuring safety, usability, and functionality of institutional facilities. |

| Key Tasks | Preventive, predictive, corrective maintenance of machines, conveyors, and industrial systems. | Repair, cleaning, HVAC, electrical, plumbing, and structural maintenance. |

| Environment | Factories, plants, warehouses with heavy machinery and specialized equipment. | Schools, hospitals, government buildings, and public institutions. |

| Skills Required | Technical skills in mechanical, electrical, and automation systems. | General maintenance skills including plumbing, carpentry, and electrical work. |

| Goal | Maximize production uptime and extend equipment lifespan. | Maintain safe, clean, and functional institutional environments. |

| Maintenance Frequency | Regularly scheduled based on production cycles and equipment usage. | Routine and as-needed based on usage and building inspection results. |

Definition of Industrial Maintenance

Industrial maintenance involves the systematic inspection, repair, and upkeep of machinery and equipment used in manufacturing and production facilities. It ensures optimal performance, reduces downtime, and extends the lifespan of critical industrial assets. This type of maintenance focuses on mechanical, electrical, and hydraulic systems essential for industrial operations.

Definition of Institutional Maintenance

Institutional maintenance refers to the scheduled upkeep and repair activities carried out within facilities such as schools, hospitals, government buildings, and other public institutions to ensure their operational efficiency and safety. This type of maintenance emphasizes preserving the building's infrastructure, systems, and equipment to meet regulatory standards and support continuous institutional functions. It often involves specialized tasks like HVAC servicing, plumbing repairs, electrical system checks, and routine inspections tailored to the unique needs of institutional environments.

Key Differences Between Industrial and Institutional Maintenance

Industrial maintenance primarily involves the upkeep and repair of machinery, equipment, and production systems in manufacturing plants, emphasizing minimizing downtime and ensuring operational efficiency. Institutional maintenance focuses on the maintenance of facilities such as schools, hospitals, and government buildings, prioritizing safety, cleanliness, and compliance with regulatory standards. Key differences include the complexity of machinery handled, the maintenance objectives, and the specialized skills required, with industrial maintenance demanding technical expertise in mechanical and electrical systems, while institutional maintenance requires knowledge of building systems and regulatory compliance.

Core Responsibilities in Industrial Maintenance

Industrial maintenance centers on the upkeep and repair of machinery, equipment, and production systems to ensure continuous manufacturing operations. Core responsibilities include preventive maintenance, troubleshooting mechanical failures, and optimizing equipment performance to minimize downtime. This contrasts with institutional maintenance, which primarily addresses building systems such as HVAC, plumbing, and electrical infrastructure in facilities like schools and hospitals.

Core Responsibilities in Institutional Maintenance

Core responsibilities in institutional maintenance include ensuring the operational efficiency of critical building systems such as HVAC, electrical, plumbing, and fire safety to support environments like schools, hospitals, and government facilities. Routine inspections, preventive maintenance schedules, and rapid response to repairs are essential to maintain safety, compliance with regulatory standards, and uninterrupted service delivery. Institutional maintenance teams also coordinate with facility management to implement upgrades and energy-efficient solutions tailored to the specific needs of public service buildings.

Required Qualifications and Skills

Industrial maintenance technicians require expertise in mechanical systems, electrical troubleshooting, and knowledge of heavy machinery to ensure seamless production processes. Institutional maintenance specialists focus on plumbing, HVAC systems, and facility management skills to maintain safe and functional environments in schools, hospitals, and government buildings. Both roles demand strong problem-solving abilities, but industrial maintenance necessitates specialized technical certifications such as PLC programming, whereas institutional maintenance prioritizes knowledge of building codes and safety regulations.

Common Equipment and Tools Used

Industrial maintenance typically utilizes heavy-duty tools such as hydraulic lifts, diagnostic scanners, and programmable logic controllers (PLCs) to service machinery like conveyors, compressors, and robotic arms. Institutional maintenance relies on versatile equipment including hand tools, power drills, and HVAC diagnostic devices to manage infrastructure systems such as boilers, elevators, and fire alarms. Both sectors prioritize safety gear, but industrial settings often require specialized personal protective equipment (PPE) due to higher operational risks.

Safety Protocols and Compliance Standards

Industrial maintenance demands strict adherence to OSHA regulations and NFPA safety standards to mitigate risks in high-risk environments such as manufacturing plants. Institutional maintenance prioritizes compliance with ADA requirements and fire safety codes specific to educational or healthcare facilities, ensuring occupant safety and accessibility. Both sectors require rigorous documentation and regular audits to maintain regulatory compliance and prevent operational hazards.

Career Growth and Advancement Opportunities

Industrial maintenance careers offer specialized skill development in machinery, automation, and manufacturing systems, providing robust opportunities for advancement into supervisory or technical expert roles. Institutional maintenance focuses on facilities management in schools, hospitals, or government buildings, with career growth often leading to facilities manager or operations coordinator positions. Both paths demand continuous training, but industrial maintenance generally offers faster progression due to high-tech equipment and industry demand.

Industry Trends and Future Outlook

Industrial maintenance increasingly integrates IoT-driven predictive analytics and automated robotics to minimize downtime and extend equipment lifecycle, aligning with Industry 4.0 advancements. Institutional maintenance trends prioritize energy-efficient systems and smart facility management platforms, driven by sustainability regulations and cost-reduction imperatives. Future outlook highlights converging technologies such as AI-powered diagnostics and augmented reality-enhanced repair workflows, revolutionizing both industrial and institutional maintenance landscapes.

Industrial Maintenance vs Institutional Maintenance Infographic

jobdiv.com

jobdiv.com