Planned maintenance involves scheduled inspections and servicing to prevent equipment failures, enhancing reliability and reducing downtime. Reactive maintenance occurs after a failure, addressing issues as they arise, which can lead to unexpected costs and extended equipment outages. Implementing planned maintenance strategies helps optimize operational efficiency and extend the lifespan of assets compared to relying solely on reactive approaches.

Table of Comparison

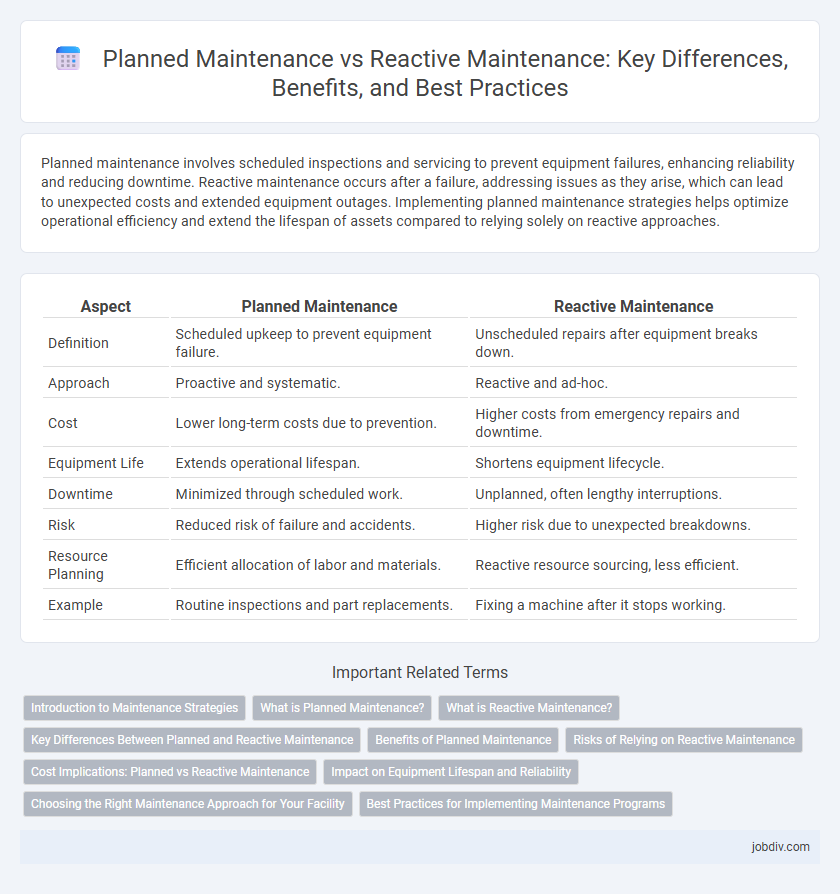

| Aspect | Planned Maintenance | Reactive Maintenance |

|---|---|---|

| Definition | Scheduled upkeep to prevent equipment failure. | Unscheduled repairs after equipment breaks down. |

| Approach | Proactive and systematic. | Reactive and ad-hoc. |

| Cost | Lower long-term costs due to prevention. | Higher costs from emergency repairs and downtime. |

| Equipment Life | Extends operational lifespan. | Shortens equipment lifecycle. |

| Downtime | Minimized through scheduled work. | Unplanned, often lengthy interruptions. |

| Risk | Reduced risk of failure and accidents. | Higher risk due to unexpected breakdowns. |

| Resource Planning | Efficient allocation of labor and materials. | Reactive resource sourcing, less efficient. |

| Example | Routine inspections and part replacements. | Fixing a machine after it stops working. |

Introduction to Maintenance Strategies

Planned maintenance involves scheduled inspections and servicing to prevent equipment failures, enhancing reliability and reducing downtime. Reactive maintenance, also known as corrective maintenance, occurs after equipment malfunctions, often leading to unexpected interruptions and higher repair costs. Choosing an effective maintenance strategy depends on balancing resource allocation, operational demands, and the criticality of assets to optimize productivity and minimize operational risks.

What is Planned Maintenance?

Planned maintenance involves scheduling routine inspections, servicing, and repairs based on time intervals or equipment usage to prevent unexpected failures and extend asset lifespan. It relies on detailed maintenance plans and historical performance data to optimize resource allocation and minimize unplanned downtime. This proactive strategy improves operational efficiency by addressing potential issues before they escalate into costly breakdowns.

What is Reactive Maintenance?

Reactive maintenance refers to the process of repairing equipment or systems only after a failure or breakdown occurs, without prior scheduling or preventive action. This approach often leads to unexpected downtime and higher repair costs compared to planned maintenance strategies. It is commonly used in situations where immediate repairs are essential, but it can negatively impact overall operational efficiency and asset lifespan.

Key Differences Between Planned and Reactive Maintenance

Planned maintenance involves scheduled inspections and routine servicing to prevent equipment failures, enhancing reliability and minimizing unplanned downtime. Reactive maintenance occurs after a failure has happened, focusing on repairing or replacing equipment, which often leads to higher costs and extended outages. The key differences lie in cost predictability, equipment lifespan extension, and overall operational efficiency, with planned maintenance optimizing long-term asset performance and reactive maintenance addressing immediate repair needs.

Benefits of Planned Maintenance

Planned maintenance reduces equipment downtime by scheduling regular inspections and repairs, enhancing operational efficiency and prolonging asset lifespan. It minimizes unexpected breakdowns, resulting in cost savings on emergency repairs and production interruptions. This proactive approach improves safety standards and ensures regulatory compliance by maintaining machinery in optimal condition.

Risks of Relying on Reactive Maintenance

Relying on reactive maintenance significantly increases the risk of unexpected equipment failures, leading to costly downtime and production losses. This approach often results in higher repair expenses due to emergency fixes and potential collateral damage to other system components. In industries such as manufacturing and aerospace, unplanned breakdowns compromise safety standards and can cause extended operational disruptions.

Cost Implications: Planned vs Reactive Maintenance

Planned maintenance typically reduces overall costs by preventing unexpected equipment failures and minimizing downtime, leading to more predictable budget allocation. Reactive maintenance often incurs higher expenses due to emergency repairs, unplanned work stoppages, and expedited parts procurement. Investing in planned maintenance strategies enhances asset longevity and operational efficiency, resulting in significant long-term cost savings compared to reactive approaches.

Impact on Equipment Lifespan and Reliability

Planned maintenance significantly extends equipment lifespan by systematically addressing wear and potential failures before they escalate, thereby enhancing overall reliability. Reactive maintenance often leads to unexpected breakdowns, causing accelerated equipment deterioration and reduced operational lifespan. Strategically implemented planned maintenance reduces downtime and repair costs, contributing to consistent equipment performance and improved reliability.

Choosing the Right Maintenance Approach for Your Facility

Selecting the appropriate maintenance strategy is crucial for maximizing equipment uptime and operational efficiency in your facility. Planned maintenance schedules routine inspections and repairs to prevent breakdowns, while reactive maintenance addresses issues only after failures occur, often causing costly downtime. Analyzing equipment criticality, maintenance costs, and operational impact helps determine the optimal balance between planned and reactive approaches, ensuring reliability and cost-effectiveness.

Best Practices for Implementing Maintenance Programs

Effective maintenance programs prioritize planned maintenance over reactive maintenance to minimize equipment downtime and extend asset lifespan. Best practices include scheduling regular inspections based on manufacturer recommendations and historical data, using predictive analytics for early fault detection, and training personnel in proactive maintenance procedures. Integrating computerized maintenance management systems (CMMS) enhances tracking, resource allocation, and continuous optimization of maintenance activities.

Planned Maintenance vs Reactive Maintenance Infographic

jobdiv.com

jobdiv.com