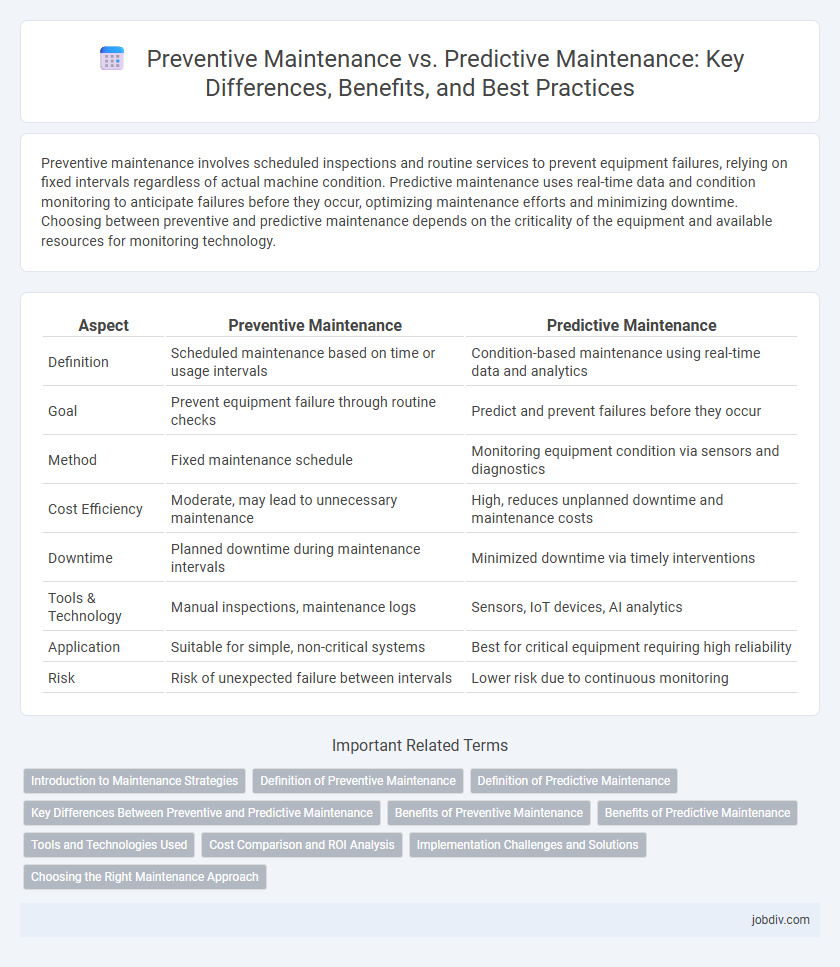

Preventive maintenance involves scheduled inspections and routine services to prevent equipment failures, relying on fixed intervals regardless of actual machine condition. Predictive maintenance uses real-time data and condition monitoring to anticipate failures before they occur, optimizing maintenance efforts and minimizing downtime. Choosing between preventive and predictive maintenance depends on the criticality of the equipment and available resources for monitoring technology.

Table of Comparison

| Aspect | Preventive Maintenance | Predictive Maintenance |

|---|---|---|

| Definition | Scheduled maintenance based on time or usage intervals | Condition-based maintenance using real-time data and analytics |

| Goal | Prevent equipment failure through routine checks | Predict and prevent failures before they occur |

| Method | Fixed maintenance schedule | Monitoring equipment condition via sensors and diagnostics |

| Cost Efficiency | Moderate, may lead to unnecessary maintenance | High, reduces unplanned downtime and maintenance costs |

| Downtime | Planned downtime during maintenance intervals | Minimized downtime via timely interventions |

| Tools & Technology | Manual inspections, maintenance logs | Sensors, IoT devices, AI analytics |

| Application | Suitable for simple, non-critical systems | Best for critical equipment requiring high reliability |

| Risk | Risk of unexpected failure between intervals | Lower risk due to continuous monitoring |

Introduction to Maintenance Strategies

Preventive maintenance involves scheduled inspections and routine tasks aimed at reducing equipment failures by addressing potential issues before they occur. Predictive maintenance leverages real-time data and advanced analytics such as vibration analysis and thermal imaging to forecast equipment degradation and optimize repair timing. Both strategies are essential for maximizing asset lifespan, minimizing downtime, and improving operational efficiency within industrial and manufacturing environments.

Definition of Preventive Maintenance

Preventive maintenance involves routine, scheduled inspections and servicing of equipment to prevent unexpected failures and prolong asset lifespan. It is based on time or usage intervals, addressing potential issues before they manifest into breakdowns. This approach reduces downtime by systematically replacing parts and performing adjustments regardless of equipment condition.

Definition of Predictive Maintenance

Predictive maintenance involves using advanced data analysis techniques and real-time monitoring to forecast equipment failures before they occur, enabling timely interventions. This approach relies on sensors, machine learning algorithms, and historical data to assess the actual condition of assets, minimizing unplanned downtime. Unlike preventive maintenance, which follows fixed schedules, predictive maintenance enhances efficiency by targeting maintenance activities based on asset health and performance trends.

Key Differences Between Preventive and Predictive Maintenance

Preventive maintenance involves scheduled inspections and servicing based on time or usage intervals to reduce equipment failure, while predictive maintenance relies on real-time data and condition monitoring to forecast potential breakdowns. Preventive maintenance reduces downtime through routine tasks, whereas predictive maintenance optimizes resource allocation by addressing issues only when indicators show a decline in performance. The key differences lie in their approach: preventive is time-based and generalized, predictive is data-driven and specific to equipment condition.

Benefits of Preventive Maintenance

Preventive maintenance reduces equipment downtime by scheduling regular inspections and servicing before failures occur, enhancing asset longevity and operational reliability. It lowers repair costs by addressing potential issues early, minimizing unexpected breakdowns and costly emergency interventions. Implementing preventive maintenance improves safety by ensuring machinery operates within optimal parameters, preventing accidents caused by equipment malfunctions.

Benefits of Predictive Maintenance

Predictive maintenance leverages real-time data and advanced analytics to accurately forecast equipment failures, reducing unplanned downtime and maintenance costs. This approach optimizes asset lifespan by enabling targeted interventions based on actual wear conditions rather than fixed schedules. Enhanced operational efficiency and improved safety are key benefits, as maintenance is performed only when necessary, preventing catastrophic failures.

Tools and Technologies Used

Preventive maintenance relies on scheduled inspections and routine tools such as vibration analyzers, thermal imaging cameras, and lubricants to detect and address equipment wear before failure occurs. Predictive maintenance employs advanced technologies like IoT sensors, machine learning algorithms, and real-time data analytics platforms to monitor asset conditions continuously and forecast potential breakdowns accurately. Combining these tools ensures optimized asset performance, reduced downtime, and efficient resource allocation in industrial maintenance.

Cost Comparison and ROI Analysis

Preventive maintenance typically involves scheduled inspections and part replacements, resulting in higher routine costs but predictable budgeting, whereas predictive maintenance uses data analytics and real-time monitoring to address issues only when necessary, reducing unexpected downtime expenses. The ROI of predictive maintenance often surpasses that of preventive maintenance due to extended equipment lifespan, fewer unplanned outages, and optimized resource allocation. Cost comparison studies indicate that predictive maintenance can reduce maintenance costs by up to 30% while increasing overall asset utilization.

Implementation Challenges and Solutions

Preventive maintenance faces challenges like scheduling downtime and over-maintaining equipment, which can lead to unnecessary costs and resource allocation inefficiencies. Predictive maintenance encounters difficulties in integrating advanced sensor technologies and interpreting complex data analytics for accurate failure predictions. Implementing IoT-enabled monitoring systems and machine learning algorithms offers effective solutions to optimize maintenance schedules and improve decision-making accuracy.

Choosing the Right Maintenance Approach

Selecting the optimal maintenance strategy depends on factors like equipment criticality, operational uptime requirements, and resource availability. Preventive maintenance schedules regular inspections and part replacements to avoid failures, while predictive maintenance uses real-time data and condition monitoring to foresee and address issues before they occur. Integrating asset management software and leveraging IoT sensors enhances decision-making between the two approaches, maximizing equipment lifespan and minimizing operational disruptions.

Preventive Maintenance vs Predictive Maintenance Infographic

jobdiv.com

jobdiv.com