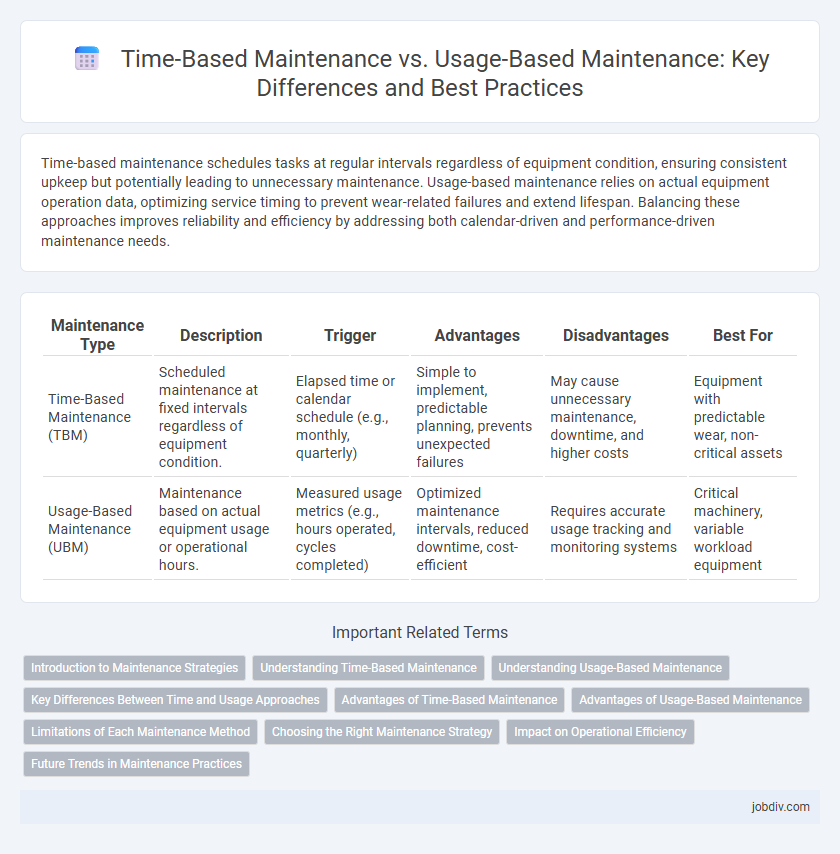

Time-based maintenance schedules tasks at regular intervals regardless of equipment condition, ensuring consistent upkeep but potentially leading to unnecessary maintenance. Usage-based maintenance relies on actual equipment operation data, optimizing service timing to prevent wear-related failures and extend lifespan. Balancing these approaches improves reliability and efficiency by addressing both calendar-driven and performance-driven maintenance needs.

Table of Comparison

| Maintenance Type | Description | Trigger | Advantages | Disadvantages | Best For |

|---|---|---|---|---|---|

| Time-Based Maintenance (TBM) | Scheduled maintenance at fixed intervals regardless of equipment condition. | Elapsed time or calendar schedule (e.g., monthly, quarterly) | Simple to implement, predictable planning, prevents unexpected failures | May cause unnecessary maintenance, downtime, and higher costs | Equipment with predictable wear, non-critical assets |

| Usage-Based Maintenance (UBM) | Maintenance based on actual equipment usage or operational hours. | Measured usage metrics (e.g., hours operated, cycles completed) | Optimized maintenance intervals, reduced downtime, cost-efficient | Requires accurate usage tracking and monitoring systems | Critical machinery, variable workload equipment |

Introduction to Maintenance Strategies

Time-based maintenance schedules inspections and servicing at regular, predetermined intervals regardless of equipment condition, optimizing predictable wear management. Usage-based maintenance relies on actual equipment usage data, such as hours of operation or production cycles, to trigger maintenance activities, enhancing efficiency and reducing unnecessary downtime. Both strategies aim to balance maintenance costs while ensuring equipment reliability and longevity.

Understanding Time-Based Maintenance

Time-Based Maintenance (TBM) schedules maintenance activities at fixed intervals regardless of equipment condition, optimizing reliability by preventing unexpected failures. It relies on historical data and manufacturer recommendations to determine maintenance frequency, ensuring components are serviced before wear causes defects. TBM reduces downtime by enabling pre-planned repairs but may lead to unnecessary part replacements if equipment usage varies significantly.

Understanding Usage-Based Maintenance

Usage-based maintenance relies on real-time data and sensor inputs to schedule upkeep based on equipment actual usage rather than fixed time intervals. This approach optimizes maintenance frequency by monitoring parameters like operating hours, cycles, or output levels, reducing unnecessary service and minimizing downtime. Understanding usage-based maintenance enables organizations to improve asset longevity, enhance operational efficiency, and lower maintenance costs through predictive decision-making.

Key Differences Between Time and Usage Approaches

Time-Based Maintenance schedules service intervals according to fixed time periods, ensuring consistent inspections regardless of equipment activity. Usage-Based Maintenance triggers maintenance based on actual operational data, such as hours run or output cycles, optimizing resource allocation and minimizing unnecessary downtime. The key difference lies in time-driven regularity versus condition-driven intervention for improved equipment reliability and efficiency.

Advantages of Time-Based Maintenance

Time-Based Maintenance ensures regular, scheduled inspections and servicing, reducing the risk of unexpected equipment failures by adhering to fixed maintenance intervals. This approach simplifies maintenance planning and resource allocation, making it easier to manage workloads and ensure consistent equipment performance. Predictable maintenance routines also extend asset lifespan by preventing wear-related damage before it occurs, enhancing overall operational reliability.

Advantages of Usage-Based Maintenance

Usage-Based Maintenance optimizes equipment longevity by scheduling upkeep based on actual operational data, reducing unnecessary service and downtime. This approach enhances cost-efficiency by targeting maintenance only when usage thresholds are met, preventing both over-maintenance and unexpected failures. Real-time monitoring enables predictive insights, improving asset reliability and overall maintenance planning accuracy.

Limitations of Each Maintenance Method

Time-Based Maintenance often leads to unnecessary part replacements and downtime since it relies on fixed schedules rather than actual equipment condition. Usage-Based Maintenance can result in unexpected failures if sensor data is inaccurate or if critical degradation occurs between measurement intervals. Both methods may incur higher costs and decreased reliability if not integrated with real-time monitoring and predictive analytics.

Choosing the Right Maintenance Strategy

Selecting the optimal maintenance strategy involves evaluating Time-Based Maintenance (TBM) against Usage-Based Maintenance (UBM), where TBM schedules services at fixed intervals while UBM relies on actual equipment usage data. For assets with predictable wear patterns, TBM reduces unexpected failures by adhering to strict maintenance timelines, whereas UBM enhances efficiency by minimizing unnecessary interventions through real-time monitoring. Incorporating sensor data and predictive analytics enables organizations to fine-tune maintenance plans, balancing cost-effectiveness and operational reliability.

Impact on Operational Efficiency

Time-Based Maintenance schedules repairs and inspections at fixed intervals, potentially leading to unnecessary downtime and excess resource allocation. Usage-Based Maintenance adjusts maintenance activities based on actual equipment usage and condition data, optimizing service timing to reduce unexpected failures and extend asset lifespan. Implementing Usage-Based Maintenance generally enhances operational efficiency by minimizing both unplanned outages and maintenance costs.

Future Trends in Maintenance Practices

Time-based maintenance, which schedules service at fixed intervals, faces limitations due to its lack of responsiveness to actual equipment condition, prompting a shift toward usage-based maintenance that triggers actions based on real operational data such as hours of use or cycles completed. Future trends indicate increased integration of IoT sensors and AI-driven analytics to enable predictive models that optimize maintenance timing, reducing downtime and costs. These advancements support a more dynamic and condition-driven approach that enhances asset reliability and extends equipment lifespan.

Time-Based Maintenance vs Usage-Based Maintenance Infographic

jobdiv.com

jobdiv.com