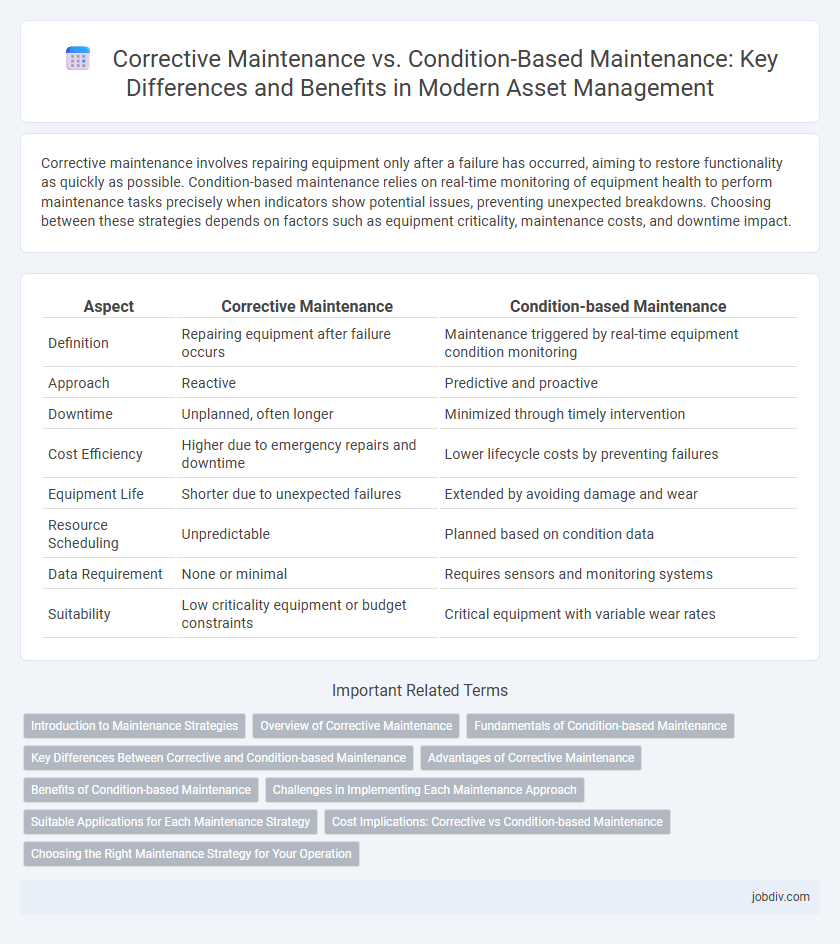

Corrective maintenance involves repairing equipment only after a failure has occurred, aiming to restore functionality as quickly as possible. Condition-based maintenance relies on real-time monitoring of equipment health to perform maintenance tasks precisely when indicators show potential issues, preventing unexpected breakdowns. Choosing between these strategies depends on factors such as equipment criticality, maintenance costs, and downtime impact.

Table of Comparison

| Aspect | Corrective Maintenance | Condition-based Maintenance |

|---|---|---|

| Definition | Repairing equipment after failure occurs | Maintenance triggered by real-time equipment condition monitoring |

| Approach | Reactive | Predictive and proactive |

| Downtime | Unplanned, often longer | Minimized through timely intervention |

| Cost Efficiency | Higher due to emergency repairs and downtime | Lower lifecycle costs by preventing failures |

| Equipment Life | Shorter due to unexpected failures | Extended by avoiding damage and wear |

| Resource Scheduling | Unpredictable | Planned based on condition data |

| Data Requirement | None or minimal | Requires sensors and monitoring systems |

| Suitability | Low criticality equipment or budget constraints | Critical equipment with variable wear rates |

Introduction to Maintenance Strategies

Corrective maintenance addresses equipment failures after they occur, focusing on repairing or replacing faulty components to restore functionality, which can lead to unplanned downtime and higher costs. Condition-based maintenance leverages real-time data and sensor monitoring to predict and prevent failures by performing maintenance only when specific indicators show signs of deterioration. Implementing condition-based strategies improves asset lifespan, reduces unexpected breakdowns, and optimizes maintenance resources by targeting interventions based on equipment condition rather than set schedules or reactive repairs.

Overview of Corrective Maintenance

Corrective Maintenance involves repairing equipment only after a failure has occurred, aiming to restore functionality as quickly as possible. It typically incurs higher downtime and unexpected costs compared to proactive strategies. This approach contrasts with Condition-based Maintenance, which monitors equipment health to prevent failures before they happen.

Fundamentals of Condition-based Maintenance

Condition-based maintenance (CBM) relies on real-time data and sensor monitoring to assess equipment health, enabling maintenance actions only when indicators show signs of deterioration or potential failure. This approach contrasts with corrective maintenance, which occurs after a fault is detected, often leading to unexpected downtime and higher repair costs. Implementing CBM improves asset reliability, optimizes maintenance schedules, and reduces unnecessary interventions by focusing on actual equipment conditions rather than fixed time intervals.

Key Differences Between Corrective and Condition-based Maintenance

Corrective maintenance involves repairing equipment after a failure has occurred, often leading to unexpected downtime and higher costs. Condition-based maintenance relies on continuous monitoring of asset conditions using sensors and data analysis to predict and address issues before failures happen. Key differences include the reactive nature of corrective maintenance versus the proactive, data-driven approach of condition-based maintenance that enhances equipment reliability and optimizes maintenance schedules.

Advantages of Corrective Maintenance

Corrective Maintenance offers advantages such as lower initial costs since repairs are performed only after equipment failure, reducing unnecessary preventive actions. It enables maintenance teams to focus resources on actual issues, minimizing downtime by addressing problems promptly when they arise. This approach also extends equipment life by fixing faults immediately, preventing further damage and ensuring operational reliability.

Benefits of Condition-based Maintenance

Condition-based maintenance enhances operational efficiency by monitoring real-time equipment health and performing repairs only when necessary, thereby reducing unexpected breakdowns and downtime. This approach extends asset lifespan and optimizes maintenance costs by preventing unnecessary interventions common in corrective maintenance. Implementing condition-based strategies leads to improved safety and reliability through early fault detection and timely maintenance actions.

Challenges in Implementing Each Maintenance Approach

Corrective maintenance faces challenges such as unexpected equipment failures leading to costly downtime and lack of predictive insights, making scheduling and resource allocation difficult. Condition-based maintenance requires advanced sensor technologies and continuous monitoring systems, which involve high initial investment and complex data analysis capabilities. Both approaches struggle with balancing cost efficiency and operational reliability while integrating with existing maintenance workflows and workforce skill sets.

Suitable Applications for Each Maintenance Strategy

Corrective Maintenance is suitable for non-critical equipment where unexpected failure has minimal impact on operations and repair costs remain manageable, such as simple machinery or utilities. Condition-based Maintenance is ideal for critical assets that require continuous monitoring to prevent costly downtime, including complex production machinery, turbines, and HVAC systems in industrial sectors. Selecting the appropriate maintenance strategy depends on factors like equipment criticality, operational impact, and available monitoring technology.

Cost Implications: Corrective vs Condition-based Maintenance

Corrective maintenance incurs higher costs due to unexpected equipment failures, unplanned downtime, and emergency repair expenses, often leading to production losses. In contrast, condition-based maintenance reduces costs by allowing timely interventions based on real-time equipment data, preventing major breakdowns and optimizing resource allocation. Investing in condition monitoring technologies typically results in lower overall maintenance expenses and improved asset lifespan.

Choosing the Right Maintenance Strategy for Your Operation

Corrective maintenance involves repairing equipment only after a failure occurs, which can lead to unplanned downtime and higher repair costs. Condition-based maintenance uses real-time monitoring data to perform maintenance activities proactively when specific indicators show deterioration, enhancing equipment reliability and reducing unnecessary interventions. Selecting the right maintenance strategy depends on factors such as operational criticality, equipment condition monitoring capabilities, and cost-benefit analyses to optimize asset longevity and minimize downtime.

Corrective Maintenance vs Condition-based Maintenance Infographic

jobdiv.com

jobdiv.com