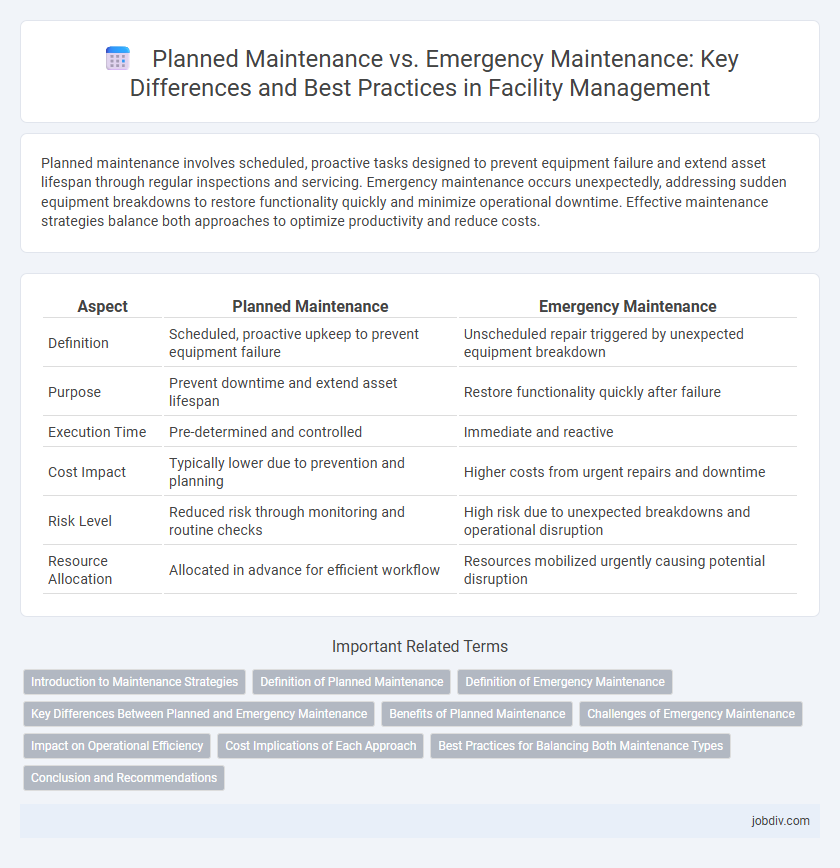

Planned maintenance involves scheduled, proactive tasks designed to prevent equipment failure and extend asset lifespan through regular inspections and servicing. Emergency maintenance occurs unexpectedly, addressing sudden equipment breakdowns to restore functionality quickly and minimize operational downtime. Effective maintenance strategies balance both approaches to optimize productivity and reduce costs.

Table of Comparison

| Aspect | Planned Maintenance | Emergency Maintenance |

|---|---|---|

| Definition | Scheduled, proactive upkeep to prevent equipment failure | Unscheduled repair triggered by unexpected equipment breakdown |

| Purpose | Prevent downtime and extend asset lifespan | Restore functionality quickly after failure |

| Execution Time | Pre-determined and controlled | Immediate and reactive |

| Cost Impact | Typically lower due to prevention and planning | Higher costs from urgent repairs and downtime |

| Risk Level | Reduced risk through monitoring and routine checks | High risk due to unexpected breakdowns and operational disruption |

| Resource Allocation | Allocated in advance for efficient workflow | Resources mobilized urgently causing potential disruption |

Introduction to Maintenance Strategies

Planned maintenance involves scheduled inspections and repairs aimed at preventing equipment failures and optimizing operational efficiency, reducing unexpected downtime. Emergency maintenance occurs in response to sudden equipment breakdowns, requiring immediate attention to restore functionality and minimize production impact. Implementing a balanced maintenance strategy integrates both planned and emergency approaches to enhance asset lifespan and operational reliability.

Definition of Planned Maintenance

Planned maintenance refers to scheduled inspections, servicing, and repairs systematically organized to prevent equipment failure and extend asset lifespan. It involves routine tasks based on time intervals or usage metrics to ensure operational efficiency and safety. This proactive approach minimizes downtime and reduces the likelihood of costly emergency interventions.

Definition of Emergency Maintenance

Emergency maintenance refers to unplanned, urgent repairs required to address sudden equipment failures or critical system breakdowns that disrupt operations. This type of maintenance prioritizes immediate action to prevent safety hazards, extensive damage, or prolonged downtime. It contrasts with planned maintenance, which is scheduled and performed to prevent such emergencies through regular inspections and servicing.

Key Differences Between Planned and Emergency Maintenance

Planned maintenance involves scheduled inspections and repairs aimed at preventing equipment failures and prolonging asset life, while emergency maintenance addresses unexpected breakdowns requiring immediate attention. Planned maintenance relies on predictive data and routine checkups, reducing downtime and optimizing resource allocation, whereas emergency maintenance incurs higher costs and operational disruptions due to its reactive nature. The key differences lie in timing, cost efficiency, and the impact on production continuity.

Benefits of Planned Maintenance

Planned maintenance significantly reduces equipment downtime by proactively addressing potential issues before they escalate into failures, ensuring consistent operational efficiency. It extends the lifespan of machinery through regular inspections and scheduled repairs, minimizing the risk of costly emergency interventions. This strategic approach improves safety standards by preventing unexpected breakdowns that could lead to hazardous situations in the workplace.

Challenges of Emergency Maintenance

Emergency maintenance poses significant challenges, including unplanned downtime that disrupts operations and increases costs. Rapid diagnosis and repair under pressure often lead to incomplete fixes or repeated failures, impacting asset reliability. Limited resources and the need for immediate response complicate coordination and safety, contrasting with the more controlled environment of planned maintenance.

Impact on Operational Efficiency

Planned maintenance schedules minimize unexpected downtime, ensuring consistent operational efficiency by allowing resources to be allocated effectively and tasks to be performed during low-impact periods. Emergency maintenance disrupts workflows and often requires immediate resource reallocation, significantly reducing productivity and increasing operational costs. Implementing a robust planned maintenance strategy improves asset reliability and reduces the frequency of costly emergency repairs, thereby enhancing overall operational efficiency.

Cost Implications of Each Approach

Planned maintenance typically reduces overall costs by preventing equipment failures and minimizing unplanned downtime through scheduled inspections and repairs. Emergency maintenance incurs higher expenses due to urgent labor, expedited parts delivery, and potential production losses caused by unexpected breakdowns. Allocating budget towards proactive planned maintenance often results in substantial long-term savings compared to reactive emergency interventions.

Best Practices for Balancing Both Maintenance Types

Effective maintenance management requires a strategic balance between planned maintenance and emergency maintenance to optimize asset performance and minimize downtime. Employing predictive analytics and condition monitoring can reduce the frequency of emergency repairs by enabling timely scheduled interventions. Establishing clear protocols and resource allocation ensures swift response to unexpected failures while maintaining routine maintenance schedules for long-term reliability.

Conclusion and Recommendations

Planned maintenance ensures system reliability by scheduling regular inspections and repairs, reducing unexpected breakdowns and operational costs. Emergency maintenance, while necessary for unanticipated failures, often results in higher expenses and extended downtime due to its reactive nature. Prioritizing a robust planned maintenance program minimizes emergency repairs and enhances overall equipment effectiveness.

Planned Maintenance vs Emergency Maintenance Infographic

jobdiv.com

jobdiv.com