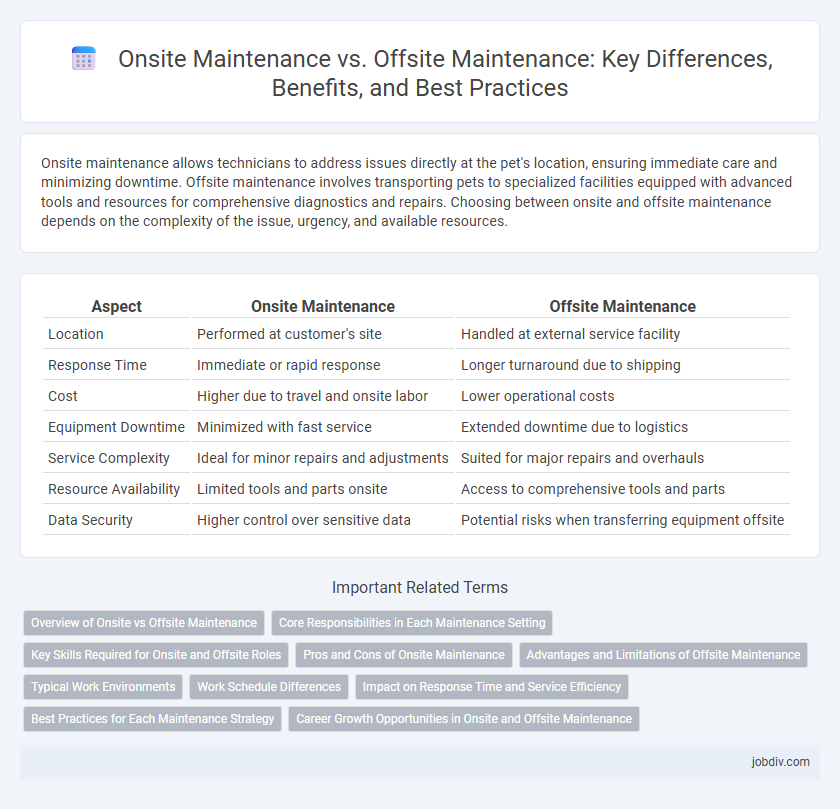

Onsite maintenance allows technicians to address issues directly at the pet's location, ensuring immediate care and minimizing downtime. Offsite maintenance involves transporting pets to specialized facilities equipped with advanced tools and resources for comprehensive diagnostics and repairs. Choosing between onsite and offsite maintenance depends on the complexity of the issue, urgency, and available resources.

Table of Comparison

| Aspect | Onsite Maintenance | Offsite Maintenance |

|---|---|---|

| Location | Performed at customer's site | Handled at external service facility |

| Response Time | Immediate or rapid response | Longer turnaround due to shipping |

| Cost | Higher due to travel and onsite labor | Lower operational costs |

| Equipment Downtime | Minimized with fast service | Extended downtime due to logistics |

| Service Complexity | Ideal for minor repairs and adjustments | Suited for major repairs and overhauls |

| Resource Availability | Limited tools and parts onsite | Access to comprehensive tools and parts |

| Data Security | Higher control over sensitive data | Potential risks when transferring equipment offsite |

Overview of Onsite vs Offsite Maintenance

Onsite maintenance involves technicians performing repairs and preventive services directly at the equipment location, ensuring immediate response and minimal downtime. Offsite maintenance requires transporting equipment to a specialized facility where in-depth diagnostics and repairs are conducted under controlled conditions. The choice between onsite and offsite maintenance depends on factors such as equipment complexity, urgency, cost, and availability of technical resources.

Core Responsibilities in Each Maintenance Setting

Onsite maintenance primarily focuses on immediate equipment repairs, routine inspections, and real-time troubleshooting to minimize downtime and maintain operational efficiency within the facility. Offsite maintenance involves comprehensive overhauls, specialized testing, and advanced diagnostics often requiring equipment to be transported to dedicated service centers with specialized tools. Both settings demand meticulous documentation and adherence to safety protocols, but onsite tasks emphasize rapid response, while offsite tasks prioritize thorough analysis and component refurbishing.

Key Skills Required for Onsite and Offsite Roles

Onsite maintenance requires strong troubleshooting skills, hands-on technical expertise, and the ability to work independently under varying environmental conditions. Offsite maintenance demands proficiency in remote diagnostics, data analysis, and communication skills to guide onsite personnel or clients effectively. Both roles benefit from knowledge of equipment standards, safety protocols, and real-time problem-solving abilities.

Pros and Cons of Onsite Maintenance

Onsite maintenance offers immediate issue resolution and minimizes equipment downtime by having technicians present at the location, which is crucial for critical systems requiring fast response times. It provides hands-on diagnostics and real-time adjustments but often involves higher costs due to travel expenses and longer technician hours onsite. Limited access to specialized tools or expertise compared to offsite facilities can sometimes restrict the complexity of repairs handled onsite.

Advantages and Limitations of Offsite Maintenance

Offsite maintenance offers the advantage of specialized repair facilities with advanced tools and skilled technicians, resulting in faster turnaround times and higher quality service. It reduces the need for onsite disruptions, allowing companies to maintain regular operations without downtime. However, offsite maintenance can lead to delays due to transportation logistics and may incur additional costs related to shipping and handling of equipment.

Typical Work Environments

Onsite maintenance typically occurs within the client's facilities, such as manufacturing plants, data centers, or office buildings, allowing technicians direct access to equipment and systems. Offsite maintenance is performed at specialized service centers or remote workshops where complex repairs or diagnostics can be conducted with advanced tools and controlled conditions. The choice between onsite and offsite maintenance depends on the urgency, complexity, and type of equipment needing service.

Work Schedule Differences

Onsite maintenance typically follows a fixed work schedule aligned with regular business hours to ensure immediate response and minimal downtime. Offsite maintenance offers more flexible scheduling options, often conducted during off-peak hours or weekends to reduce operational disruption. These differences impact resource allocation, response time, and overall maintenance efficiency.

Impact on Response Time and Service Efficiency

Onsite maintenance offers faster response times by allowing technicians to address issues directly at the location, minimizing downtime and improving overall service efficiency. Offsite maintenance may involve delays due to transportation and setup, potentially extending repair durations and reducing operational productivity. Choosing onsite support is critical for time-sensitive systems, while offsite maintenance suits less urgent repairs where resource availability and cost savings are prioritized.

Best Practices for Each Maintenance Strategy

Onsite maintenance requires skilled technicians equipped with specialized tools to perform immediate diagnostics and repairs, minimizing downtime and ensuring equipment reliability. Offsite maintenance excels when complex or extensive repairs are needed, leveraging dedicated facilities with advanced diagnostic equipment to enhance repair quality and component lifespan. Implementing clear communication protocols and detailed documentation optimizes both strategies by enabling efficient resource allocation and timely decision-making.

Career Growth Opportunities in Onsite and Offsite Maintenance

Onsite maintenance offers direct access to equipment and real-time problem-solving, enhancing hands-on skills critical for advancing to supervisory or technical specialist roles. Offsite maintenance promotes analytical expertise and remote diagnostics, fostering career growth in technical consulting and system design positions. Both paths provide distinct opportunities for professional development, with onsite roles emphasizing practical experience and offsite roles focusing on strategic and analytical competencies.

Onsite Maintenance vs Offsite Maintenance Infographic

jobdiv.com

jobdiv.com