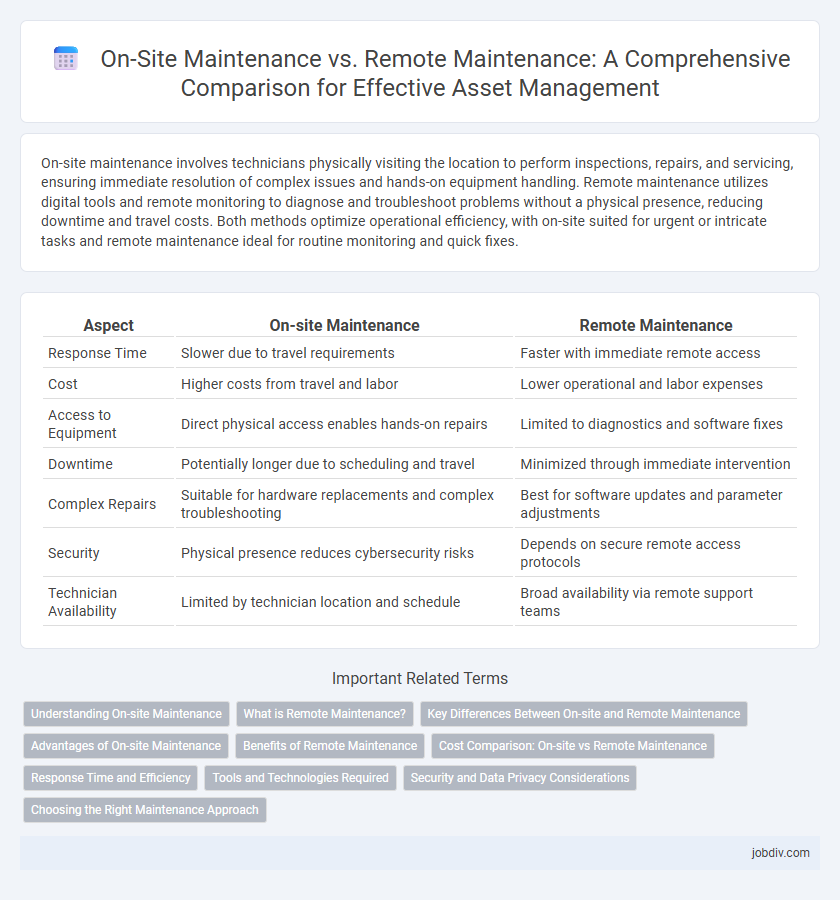

On-site maintenance involves technicians physically visiting the location to perform inspections, repairs, and servicing, ensuring immediate resolution of complex issues and hands-on equipment handling. Remote maintenance utilizes digital tools and remote monitoring to diagnose and troubleshoot problems without a physical presence, reducing downtime and travel costs. Both methods optimize operational efficiency, with on-site suited for urgent or intricate tasks and remote maintenance ideal for routine monitoring and quick fixes.

Table of Comparison

| Aspect | On-site Maintenance | Remote Maintenance |

|---|---|---|

| Response Time | Slower due to travel requirements | Faster with immediate remote access |

| Cost | Higher costs from travel and labor | Lower operational and labor expenses |

| Access to Equipment | Direct physical access enables hands-on repairs | Limited to diagnostics and software fixes |

| Downtime | Potentially longer due to scheduling and travel | Minimized through immediate intervention |

| Complex Repairs | Suitable for hardware replacements and complex troubleshooting | Best for software updates and parameter adjustments |

| Security | Physical presence reduces cybersecurity risks | Depends on secure remote access protocols |

| Technician Availability | Limited by technician location and schedule | Broad availability via remote support teams |

Understanding On-site Maintenance

On-site maintenance involves technicians physically visiting the equipment location to perform inspections, repairs, and upgrades, ensuring immediate hands-on troubleshooting and resolution. This approach facilitates direct interaction with machinery, enabling accurate diagnostics and quick response to complex technical issues that remote methods may not address effectively. Understanding on-site maintenance is crucial for optimizing operational uptime and maintaining equipment integrity in environments where physical presence is necessary.

What is Remote Maintenance?

Remote maintenance involves monitoring, diagnosing, and repairing equipment or systems from a distant location using internet connectivity and specialized software. This approach reduces downtime by allowing technicians to quickly identify issues and implement solutions without the need for physical presence on-site. Remote maintenance enhances efficiency, lowers travel costs, and supports real-time data analysis for proactive system management.

Key Differences Between On-site and Remote Maintenance

On-site maintenance requires physical presence of technicians at the equipment's location, enabling direct inspection, hands-on repairs, and immediate troubleshooting, which is crucial for complex or hardware-intensive issues. Remote maintenance leverages digital tools and connectivity to diagnose and resolve problems without on-site visits, reducing downtime and travel costs while enabling rapid response for software or configuration-related tasks. The key differences center on accessibility, cost efficiency, and the nature of the maintenance task, with on-site maintenance excelling in hardware interventions and remote maintenance optimizing speed and operational continuity.

Advantages of On-site Maintenance

On-site maintenance enables technicians to perform immediate diagnostics and repairs, reducing downtime and minimizing disruption to operations. Physical presence allows for hands-on access to equipment, facilitating thorough inspections and complex troubleshooting that remote methods may not handle effectively. This approach also enhances communication with on-site staff, ensuring precise understanding of issues and faster resolution.

Benefits of Remote Maintenance

Remote maintenance reduces downtime by enabling instant diagnostics and software updates without the need for physical presence, leading to faster issue resolution. It minimizes travel costs and resource allocation, allowing technicians to manage multiple sites more efficiently. Enhanced data collection and real-time monitoring improve predictive maintenance, preventing failures before they occur.

Cost Comparison: On-site vs Remote Maintenance

On-site maintenance typically incurs higher costs due to labor, travel expenses, and equipment transport, whereas remote maintenance reduces these expenses by enabling technicians to diagnose and resolve issues digitally. Remote maintenance leverages tools such as remote monitoring systems and VR diagnostics, minimizing downtime and operational disruptions. Companies often save up to 40% in maintenance costs by adopting remote services compared to traditional on-site interventions.

Response Time and Efficiency

On-site maintenance offers faster initial response times due to immediate physical presence, enabling quick diagnosis and repair of complex equipment failures. Remote maintenance enhances overall efficiency by providing real-time monitoring and troubleshooting without travel delays, reducing downtime and operational costs. Combining both approaches can optimize response time and maintenance efficiency, ensuring critical issues are resolved promptly while routine monitoring remains cost-effective.

Tools and Technologies Required

On-site maintenance requires specialized diagnostic tools, calibrated instruments, and physical replacement parts to troubleshoot and repair equipment directly at the location. Remote maintenance leverages advanced software platforms, IoT sensors, and real-time data analytics to monitor system performance and perform virtual diagnostics without physical presence. Integration of AI-powered remote assistance tools and cloud-based management systems enhances efficiency in identifying and resolving technical issues remotely.

Security and Data Privacy Considerations

On-site maintenance ensures direct physical control over sensitive systems, reducing risks related to unauthorized data access and enhancing compliance with strict security protocols. Remote maintenance relies heavily on secure communication channels and encryption technologies to protect data integrity and confidentiality during troubleshooting. Implementing multi-factor authentication and rigorous access controls is critical to safeguarding against potential cyber threats in remote maintenance environments.

Choosing the Right Maintenance Approach

Selecting the appropriate maintenance strategy involves evaluating factors such as equipment complexity, urgency, and available resources to determine whether on-site or remote maintenance is more effective. On-site maintenance provides hands-on diagnostics and repairs for critical or complex issues, while remote maintenance offers faster troubleshooting and cost efficiency for software updates and minor fixes. Businesses must balance downtime costs, technician accessibility, and security protocols to optimize maintenance response and operational continuity.

On-site Maintenance vs Remote Maintenance Infographic

jobdiv.com

jobdiv.com