Condition-based maintenance relies on real-time data and sensor monitoring to perform repairs only when equipment shows signs of wear or failure, optimizing resource use and minimizing downtime. Time-based maintenance schedules routine service at fixed intervals regardless of equipment condition, which can lead to unnecessary maintenance or unexpected breakdowns. Choosing between condition-based and time-based maintenance depends on factors such as equipment criticality, cost constraints, and available technology for accurate condition monitoring.

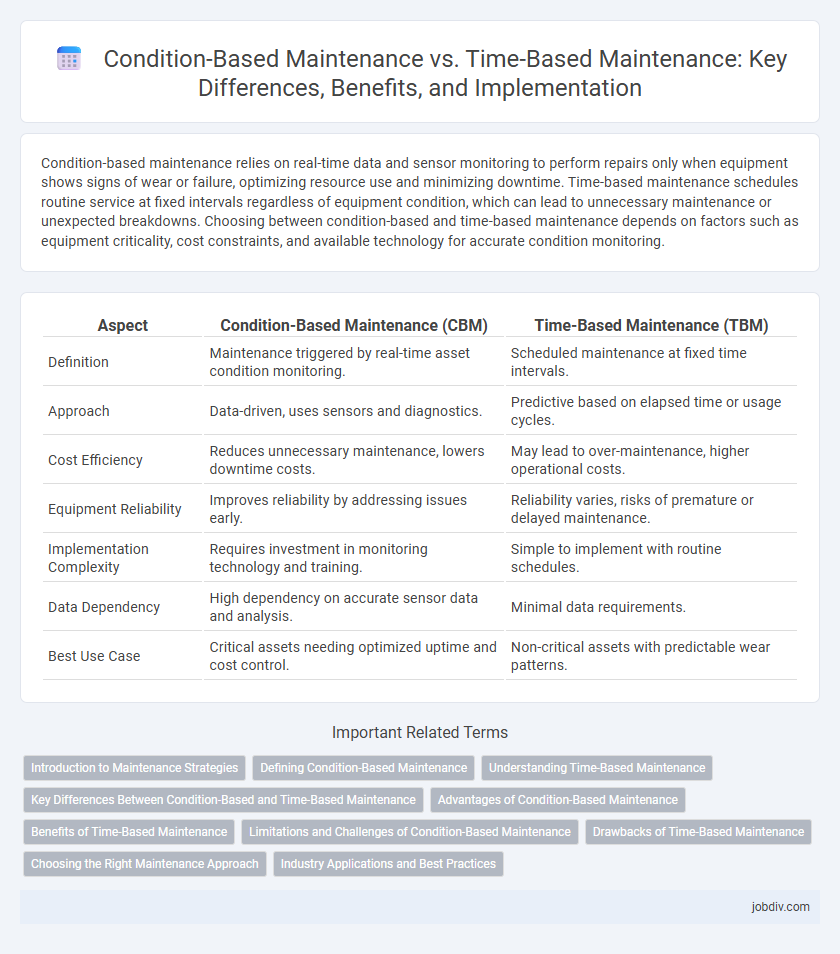

Table of Comparison

| Aspect | Condition-Based Maintenance (CBM) | Time-Based Maintenance (TBM) |

|---|---|---|

| Definition | Maintenance triggered by real-time asset condition monitoring. | Scheduled maintenance at fixed time intervals. |

| Approach | Data-driven, uses sensors and diagnostics. | Predictive based on elapsed time or usage cycles. |

| Cost Efficiency | Reduces unnecessary maintenance, lowers downtime costs. | May lead to over-maintenance, higher operational costs. |

| Equipment Reliability | Improves reliability by addressing issues early. | Reliability varies, risks of premature or delayed maintenance. |

| Implementation Complexity | Requires investment in monitoring technology and training. | Simple to implement with routine schedules. |

| Data Dependency | High dependency on accurate sensor data and analysis. | Minimal data requirements. |

| Best Use Case | Critical assets needing optimized uptime and cost control. | Non-critical assets with predictable wear patterns. |

Introduction to Maintenance Strategies

Condition-Based Maintenance (CBM) utilizes real-time data from sensors and diagnostic tools to monitor equipment health and predict failures, optimizing maintenance schedules and reducing downtime. Time-Based Maintenance (TBM), on the other hand, relies on predetermined intervals regardless of actual equipment condition, often leading to unnecessary maintenance or unexpected breakdowns. Implementing CBM can enhance operational efficiency and extend asset lifespan compared to the traditional TBM approach.

Defining Condition-Based Maintenance

Condition-Based Maintenance (CBM) utilizes real-time data from sensors and diagnostic tools to monitor equipment health, enabling maintenance actions only when specific indicators show signs of potential failure. This proactive approach contrasts with Time-Based Maintenance, which schedules service at predetermined intervals regardless of actual equipment condition. Implementing CBM reduces downtime and lowers maintenance costs by targeting resources efficiently and preventing unexpected breakdowns.

Understanding Time-Based Maintenance

Time-Based Maintenance (TBM) schedules maintenance activities at predetermined intervals regardless of equipment condition, ensuring systematic upkeep to prevent failures. This approach relies on historical data and usage patterns to define specific timeframes for inspections, replacements, or servicing, optimizing asset reliability and lifespan. TBM is effective for equipment with predictable wear rates but may result in unnecessary maintenance if actual conditions remain optimal.

Key Differences Between Condition-Based and Time-Based Maintenance

Condition-Based Maintenance (CBM) relies on real-time data and sensor monitoring to predict equipment failures, optimizing maintenance schedules based on actual machine conditions. Time-Based Maintenance (TBM) follows a fixed schedule dictated by predetermined intervals regardless of equipment status, often leading to unnecessary maintenance or unexpected breakdowns. The key differences lie in CBM's reliance on continuous condition monitoring for proactive interventions versus TBM's routine, calendar-driven approach without direct consideration of equipment health.

Advantages of Condition-Based Maintenance

Condition-Based Maintenance (CBM) optimizes asset performance by utilizing real-time data from sensors and IoT devices to predict failures and schedule maintenance precisely when needed. This approach reduces unplanned downtime and maintenance costs compared to Time-Based Maintenance, which relies on fixed schedules regardless of equipment condition. Enhanced operational efficiency and extended equipment lifespan are direct benefits of implementing CBM in industrial settings.

Benefits of Time-Based Maintenance

Time-Based Maintenance (TBM) offers predictable scheduling that minimizes unexpected equipment failures and reduces downtime by adhering to fixed service intervals. Implementing TBM can streamline maintenance operations and facilitate efficient resource allocation, improving overall operational reliability. Regular, time-driven servicing also helps extend asset lifespan by preventing wear-related issues before critical faults occur.

Limitations and Challenges of Condition-Based Maintenance

Condition-Based Maintenance (CBM) faces limitations such as reliance on accurate real-time data and sophisticated sensor technology, which may lead to increased implementation costs and complexity. Challenges include difficulty in predicting failures for components lacking clear condition indicators and the need for skilled personnel to interpret diagnostic data effectively. Inconsistent sensor performance and data integration issues can also compromise maintenance decision accuracy in CBM systems.

Drawbacks of Time-Based Maintenance

Time-Based Maintenance (TBM) often leads to unnecessary part replacements and increased downtime due to fixed schedules that do not account for actual equipment condition. This approach can result in higher operational costs and reduced asset lifespan because maintenance may be performed either too early or too late. In contrast, Condition-Based Maintenance (CBM) uses real-time data to optimize maintenance intervals, minimizing unnecessary interventions and improving reliability.

Choosing the Right Maintenance Approach

Choosing the right maintenance approach depends on factors such as equipment criticality, operational environment, and cost implications. Condition-Based Maintenance (CBM) leverages real-time data and predictive analytics to address issues before failure, optimizing uptime and resource allocation. Time-Based Maintenance (TBM) applies scheduled interventions based on fixed intervals, providing simplicity and reliability when condition monitoring is impractical or cost-prohibitive.

Industry Applications and Best Practices

Condition-Based Maintenance (CBM) leverages real-time data from sensors and IoT devices to predict equipment failures, optimizing maintenance schedules in industries such as manufacturing, aerospace, and energy. Time-Based Maintenance (TBM) relies on predefined intervals, suitable for simpler systems with predictable wear patterns commonly found in automotive and HVAC sectors. Best practices involve integrating CBM with advanced analytics for critical assets while using TBM for non-critical equipment to balance cost-efficiency and operational reliability.

Condition-Based Maintenance vs Time-Based Maintenance Infographic

jobdiv.com

jobdiv.com