Proactive maintenance involves regularly scheduled inspections and repairs to prevent equipment failures and extend asset lifespan. Deferred maintenance occurs when necessary upkeep is postponed, often leading to increased repair costs and unexpected downtime. Prioritizing proactive maintenance reduces long-term expenses and enhances operational efficiency.

Table of Comparison

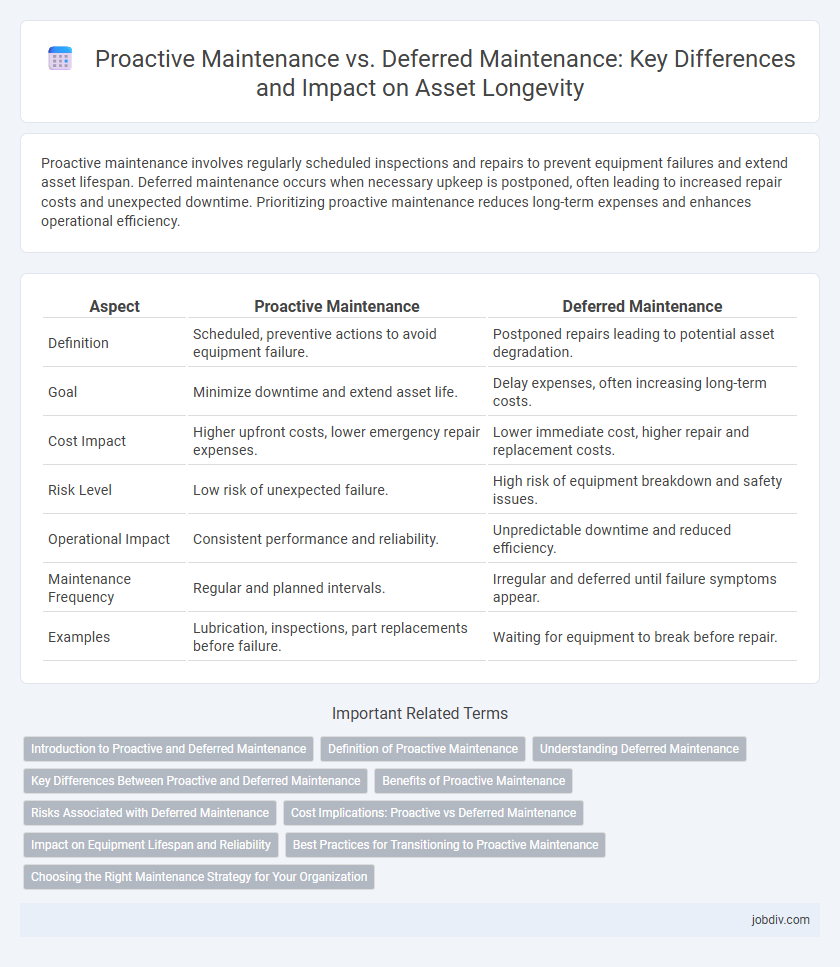

| Aspect | Proactive Maintenance | Deferred Maintenance |

|---|---|---|

| Definition | Scheduled, preventive actions to avoid equipment failure. | Postponed repairs leading to potential asset degradation. |

| Goal | Minimize downtime and extend asset life. | Delay expenses, often increasing long-term costs. |

| Cost Impact | Higher upfront costs, lower emergency repair expenses. | Lower immediate cost, higher repair and replacement costs. |

| Risk Level | Low risk of unexpected failure. | High risk of equipment breakdown and safety issues. |

| Operational Impact | Consistent performance and reliability. | Unpredictable downtime and reduced efficiency. |

| Maintenance Frequency | Regular and planned intervals. | Irregular and deferred until failure symptoms appear. |

| Examples | Lubrication, inspections, part replacements before failure. | Waiting for equipment to break before repair. |

Introduction to Proactive and Deferred Maintenance

Proactive maintenance involves regularly scheduled inspections and repairs to prevent equipment failures and extend asset life, emphasizing early detection and correction. Deferred maintenance refers to postponing necessary repairs or upkeep due to budget constraints or operational priorities, which can lead to increased downtime and higher long-term costs. Understanding these approaches is crucial for optimizing maintenance strategies and ensuring operational efficiency.

Definition of Proactive Maintenance

Proactive maintenance involves regularly scheduled inspections and servicing to prevent equipment failures before they occur, ensuring optimal operational efficiency and extending asset lifespan. This strategy uses condition-monitoring tools and predictive analytics to identify potential issues early and address them promptly. By focusing on prevention, proactive maintenance reduces unplanned downtime and lowers long-term repair costs compared to deferred maintenance approaches.

Understanding Deferred Maintenance

Deferred maintenance refers to the deliberate postponement of preventive or corrective maintenance tasks due to budget constraints, resource limitations, or operational demands. This practice can lead to increased equipment failures, higher repair costs, and reduced asset lifespan if not managed properly. Understanding deferred maintenance involves evaluating the risks and potential impacts on system reliability and prioritizing critical repairs to avoid costly downtime.

Key Differences Between Proactive and Deferred Maintenance

Proactive maintenance involves scheduled inspections and repairs aimed at preventing equipment failures, while deferred maintenance is the postponement of necessary repairs due to budget constraints or resource limitations. Key differences include the impact on asset lifespan, with proactive maintenance extending operational efficiency and deferred maintenance increasing the risk of unexpected breakdowns and higher long-term costs. Proactive maintenance prioritizes early detection and resolution, whereas deferred maintenance focuses on immediate cost savings at the expense of future reliability.

Benefits of Proactive Maintenance

Proactive maintenance enhances equipment reliability by identifying and addressing potential issues before they lead to failures, reducing unexpected downtime and costly emergency repairs. It extends asset lifespan and optimizes operational efficiency through scheduled inspections and timely interventions. This approach minimizes production disruptions, improves safety standards, and lowers total maintenance costs compared to deferred maintenance strategies.

Risks Associated with Deferred Maintenance

Deferred maintenance significantly increases the risk of equipment failure, leading to costly emergency repairs and unexpected downtime. Ignoring regular upkeep accelerates asset deterioration, reducing operational efficiency and lifespan. Deferred maintenance also raises safety hazards for workers and compliance issues with regulatory standards, dramatically impacting overall facility performance.

Cost Implications: Proactive vs Deferred Maintenance

Proactive maintenance minimizes long-term costs by addressing equipment issues early, preventing expensive breakdowns and production downtime. Deferred maintenance often leads to higher repair expenses, accelerated asset degradation, and increased operational disruptions. Investing in proactive strategies enhances budget predictability and reduces the financial risks associated with unexpected failures.

Impact on Equipment Lifespan and Reliability

Proactive maintenance significantly extends equipment lifespan by addressing issues before they cause failures, enhancing overall reliability and reducing downtime costs. Deferred maintenance leads to increased wear and tear, escalating the risk of unexpected breakdowns and costly repairs that shorten equipment life. Prioritizing proactive strategies results in more consistent performance and long-term asset value preservation.

Best Practices for Transitioning to Proactive Maintenance

Establishing a comprehensive asset management system is essential for transitioning to proactive maintenance, enabling real-time monitoring and predictive analytics to anticipate equipment failures before they occur. Training maintenance personnel on data-driven decision-making and integrating Internet of Things (IoT) sensors ensures timely detection of anomalies and reduces unplanned downtime. Implementing a phased approach with clear performance metrics allows organizations to gradually shift resources from deferred maintenance tasks to proactive strategies, optimizing maintenance budgets and extending asset lifespan.

Choosing the Right Maintenance Strategy for Your Organization

Selecting the appropriate maintenance strategy requires evaluating factors such as equipment criticality, budget constraints, and downtime tolerance. Proactive maintenance minimizes unexpected failures through regular inspections and early issue detection, reducing long-term costs and extending asset lifespan. Deferred maintenance, while cost-saving in the short term, increases risk of costly breakdowns and operational disruptions, making it vital to balance immediate expenses against potential future losses.

Proactive Maintenance vs Deferred Maintenance Infographic

jobdiv.com

jobdiv.com