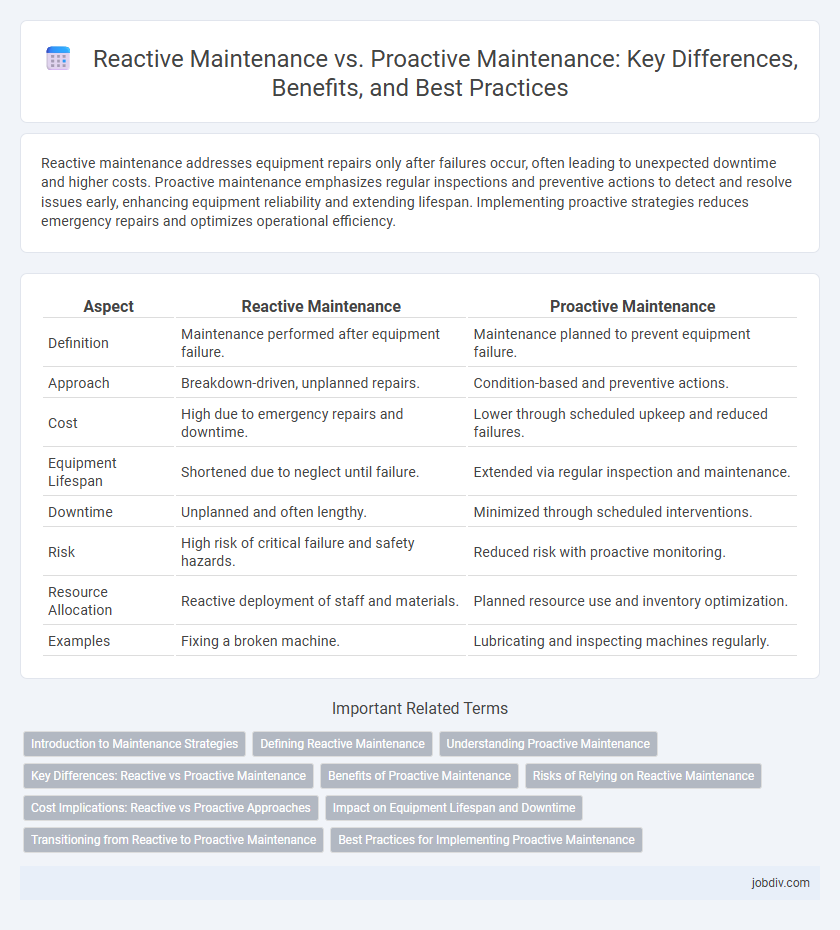

Reactive maintenance addresses equipment repairs only after failures occur, often leading to unexpected downtime and higher costs. Proactive maintenance emphasizes regular inspections and preventive actions to detect and resolve issues early, enhancing equipment reliability and extending lifespan. Implementing proactive strategies reduces emergency repairs and optimizes operational efficiency.

Table of Comparison

| Aspect | Reactive Maintenance | Proactive Maintenance |

|---|---|---|

| Definition | Maintenance performed after equipment failure. | Maintenance planned to prevent equipment failure. |

| Approach | Breakdown-driven, unplanned repairs. | Condition-based and preventive actions. |

| Cost | High due to emergency repairs and downtime. | Lower through scheduled upkeep and reduced failures. |

| Equipment Lifespan | Shortened due to neglect until failure. | Extended via regular inspection and maintenance. |

| Downtime | Unplanned and often lengthy. | Minimized through scheduled interventions. |

| Risk | High risk of critical failure and safety hazards. | Reduced risk with proactive monitoring. |

| Resource Allocation | Reactive deployment of staff and materials. | Planned resource use and inventory optimization. |

| Examples | Fixing a broken machine. | Lubricating and inspecting machines regularly. |

Introduction to Maintenance Strategies

Reactive maintenance involves addressing equipment failures only after they occur, leading to unplanned downtime and potentially higher repair costs. Proactive maintenance focuses on condition monitoring and predictive techniques to prevent breakdowns, increasing asset lifespan and operational efficiency. Implementing a balanced maintenance strategy enhances reliability and reduces unexpected disruptions in industrial settings.

Defining Reactive Maintenance

Reactive maintenance refers to the strategy of addressing equipment failures and malfunctions only after they occur, often leading to unplanned downtime and higher repair costs. This approach relies heavily on immediate response to breakdowns rather than preventive measures, which can increase the risk of extended operational interruptions. Reactive maintenance is typically utilized in situations where equipment redundancy exists or when preventive maintenance is cost-prohibitive.

Understanding Proactive Maintenance

Proactive maintenance focuses on preventing equipment failures by regularly inspecting, servicing, and predicting potential issues using data analysis and condition monitoring. This approach minimizes downtime and extends asset lifespan by addressing problems before they occur, leveraging technologies like IoT sensors and predictive analytics. Implementing proactive maintenance strategies leads to improved operational efficiency and reduced overall maintenance costs compared to reactive maintenance.

Key Differences: Reactive vs Proactive Maintenance

Reactive maintenance involves repairing equipment only after a failure occurs, leading to unexpected downtime and higher repair costs, whereas proactive maintenance emphasizes regular inspections and preventive actions to avoid breakdowns. Proactive maintenance utilizes data-driven strategies such as predictive analytics and condition monitoring to extend asset lifespan and improve reliability. Reactive approaches typically result in emergency repairs and increased operational disruptions, while proactive methods optimize maintenance schedules and reduce long-term expenses.

Benefits of Proactive Maintenance

Proactive maintenance significantly reduces equipment downtime by identifying and addressing potential issues before they escalate into costly failures. This approach extends asset lifespan, improves safety, and lowers overall maintenance costs through scheduled inspections and predictive analytics. Implementing proactive maintenance enhances operational efficiency and ensures consistent production quality.

Risks of Relying on Reactive Maintenance

Relying on reactive maintenance significantly increases the risk of unexpected equipment failures, leading to costly downtime and emergency repair expenses. This approach often results in reduced asset lifespan and compromised safety due to delayed detection of underlying issues. Organizations that depend solely on reactive maintenance face higher operational disruptions and unpredictable maintenance costs compared to those implementing proactive strategies.

Cost Implications: Reactive vs Proactive Approaches

Reactive maintenance often incurs higher costs due to unexpected equipment failures, emergency repairs, and unplanned downtime, which disrupt operations and escalate labor expenses. Proactive maintenance minimizes these expenses by scheduling regular inspections, early problem detection, and timely interventions, preventing costly breakdowns and extending asset lifespan. Implementing proactive strategies results in improved budget predictability and reduced total cost of ownership for industrial machinery and infrastructure.

Impact on Equipment Lifespan and Downtime

Reactive maintenance, often triggered by equipment failure, typically leads to shorter equipment lifespan and increased downtime due to unplanned repairs and emergency interventions. Proactive maintenance, including preventive and predictive strategies, extends equipment lifespan by addressing issues before they cause failure, significantly reducing downtime and enhancing operational efficiency. Implementing proactive maintenance practices results in lower repair costs and improved asset reliability compared to reactive maintenance approaches.

Transitioning from Reactive to Proactive Maintenance

Transitioning from reactive to proactive maintenance involves shifting from fixing equipment only after failure to implementing scheduled inspections and predictive analytics to prevent breakdowns. Emphasizing condition monitoring technologies and data-driven decision-making enhances asset reliability and reduces downtime. This strategic evolution optimizes maintenance costs and extends machinery lifespan by addressing issues before they escalate.

Best Practices for Implementing Proactive Maintenance

Implementing proactive maintenance requires establishing a comprehensive asset management system that leverages real-time data monitoring and predictive analytics to identify potential equipment failures before they occur. Best practices include scheduling regular inspections, utilizing condition-based maintenance techniques, and investing in employee training for early fault detection. Prioritizing proactive approaches reduces downtime, lowers repair costs, and extends asset lifespan compared to reactive maintenance strategies.

Reactive Maintenance vs Proactive Maintenance Infographic

jobdiv.com

jobdiv.com